Welding pipeline flaw detection clamping device

A clamping device and pipeline technology, applied in workpiece clamping devices, material analysis using radiation, manufacturing tools, etc., can solve problems such as lack of flaw detection pipeline clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

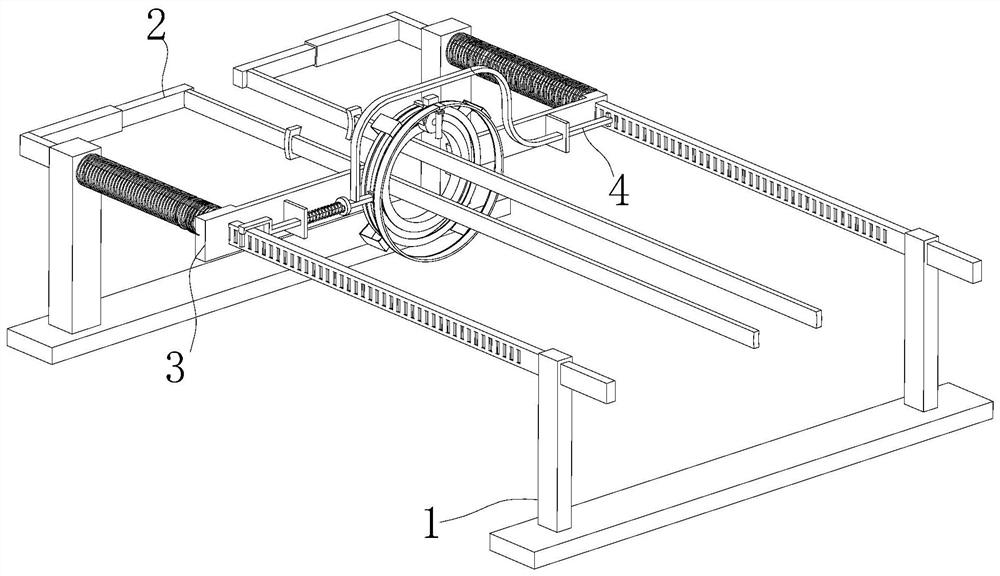

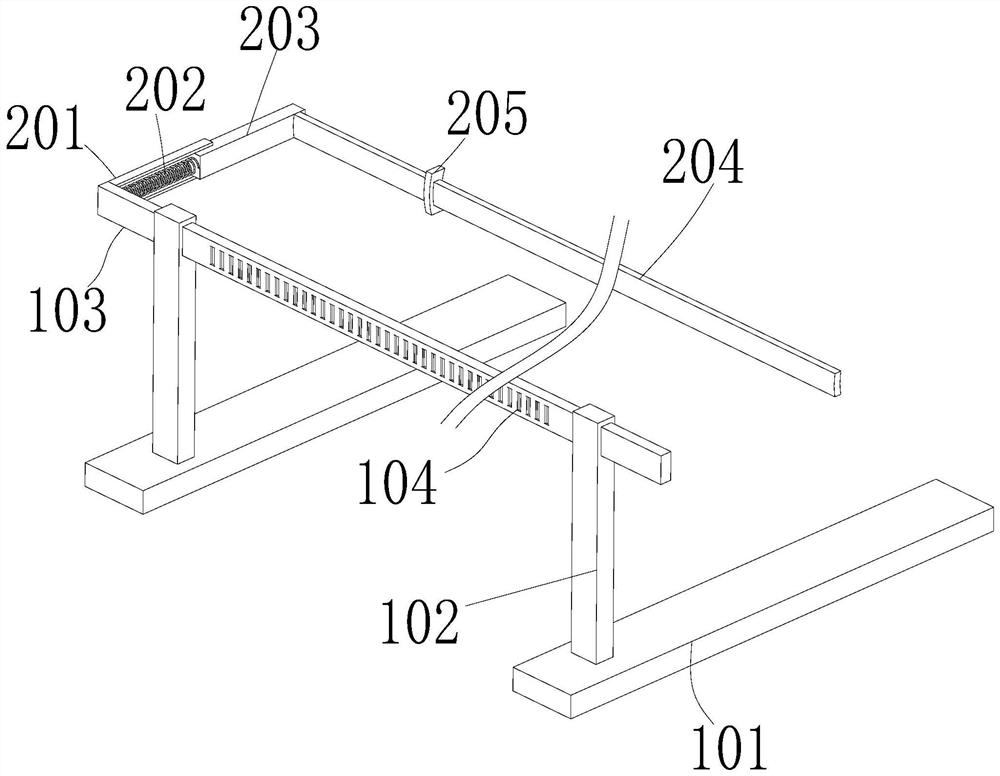

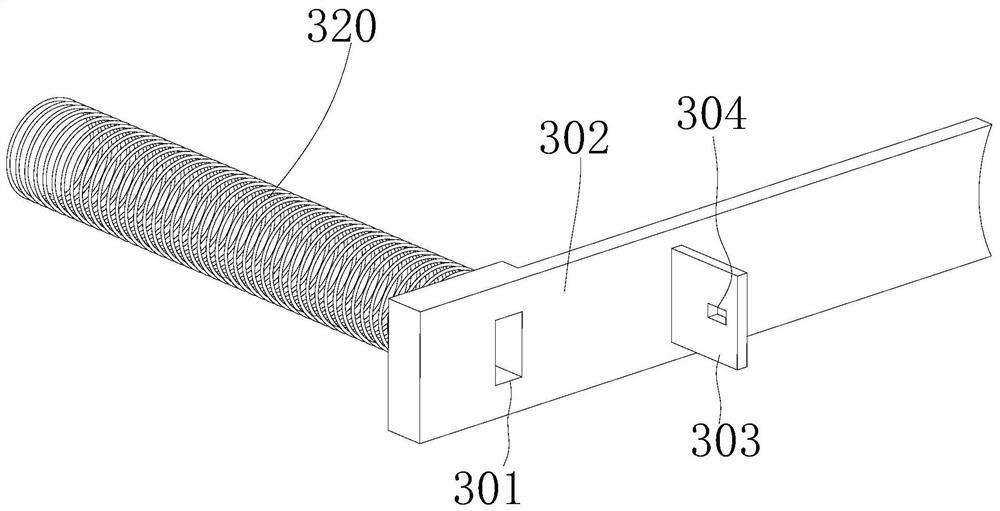

[0026] Embodiment one, such as Figure 1-4As shown, it includes a supporting mechanism 1. The function of the supporting mechanism 1 is to support the whole device. The inner rear end of the supporting mechanism 1 is fixedly installed with a clamping mechanism 2. The function of the clamping mechanism 2 is to clamp, and the clamping mechanism 2 is socketed Inside the detection pipeline, the outer surface of the support mechanism 1 is slidably connected with a fixing mechanism 3, and the front end of the fixing mechanism 3 is slidably connected with a limit mechanism 4, and the limit mechanism 4 can control the fixed mechanism 3 to move forward. The support mechanism 1 is clamped, and the support mechanism 1 includes two base plates 101, which are arranged symmetrically front and rear, and support rods 102 are fixedly installed on the upper surface of the base plate 101, and the tops of the front and rear two support rods 102 are fixedly connected by rail rods 103, The left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com