System and method for real-time workpiece surface detection and tool life prediction

A tool life, workpiece surface technology, applied in the field of edge computing and CNC machine tools, can solve the problems of low accuracy of tool life prediction and poor real-time performance of cloud data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

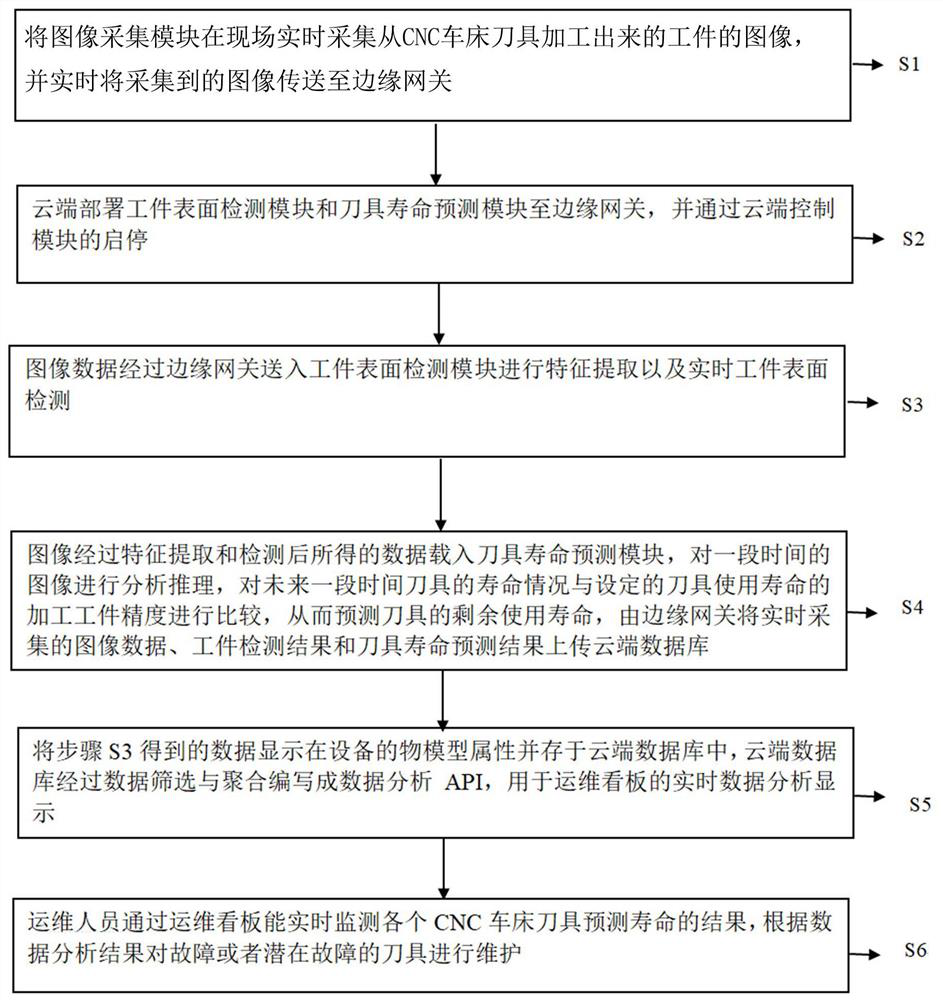

[0032] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

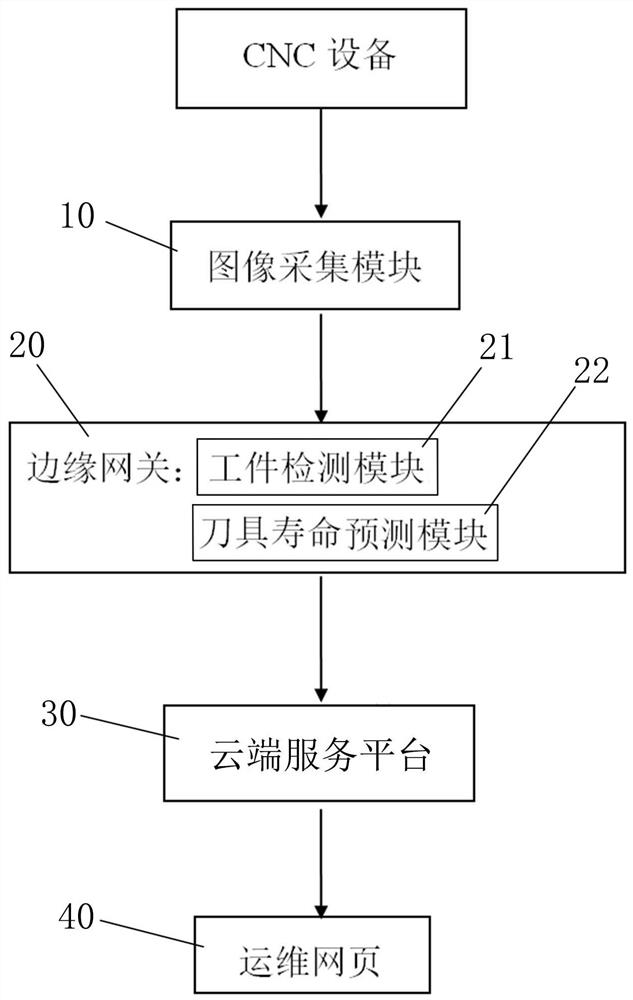

[0033] refer to figure 1Shown is a schematic diagram of the system framework of the present invention. The present invention relates to a system for real-time workpiece surface detection and tool life prediction. Based on edge computing, the system includes an image acquisition module 10, a workpiece surface detection module 21, a tool life prediction module 22, an edge gateway 20, a cloud service platform 30 and Operations and Maintenance Page 40. The image acquisition module 10 collects images of workpieces processed by CNC lathe tools in real time. The image acquisition module includes industrial cameras, lenses and light sources and is installed and fixed on the industrial manipulator together to facilitate image acquisition. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com