Water cooling system for thermal load chopper

A chopper and thermal load technology, applied in the field of thermal load chopper water cooling cooling system, can solve the problems of small high-energy X-ray beam spot, inability to work for a long time, small divergence, etc., to improve heat dissipation effect and prolong continuous work The effect of duration and avoiding heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

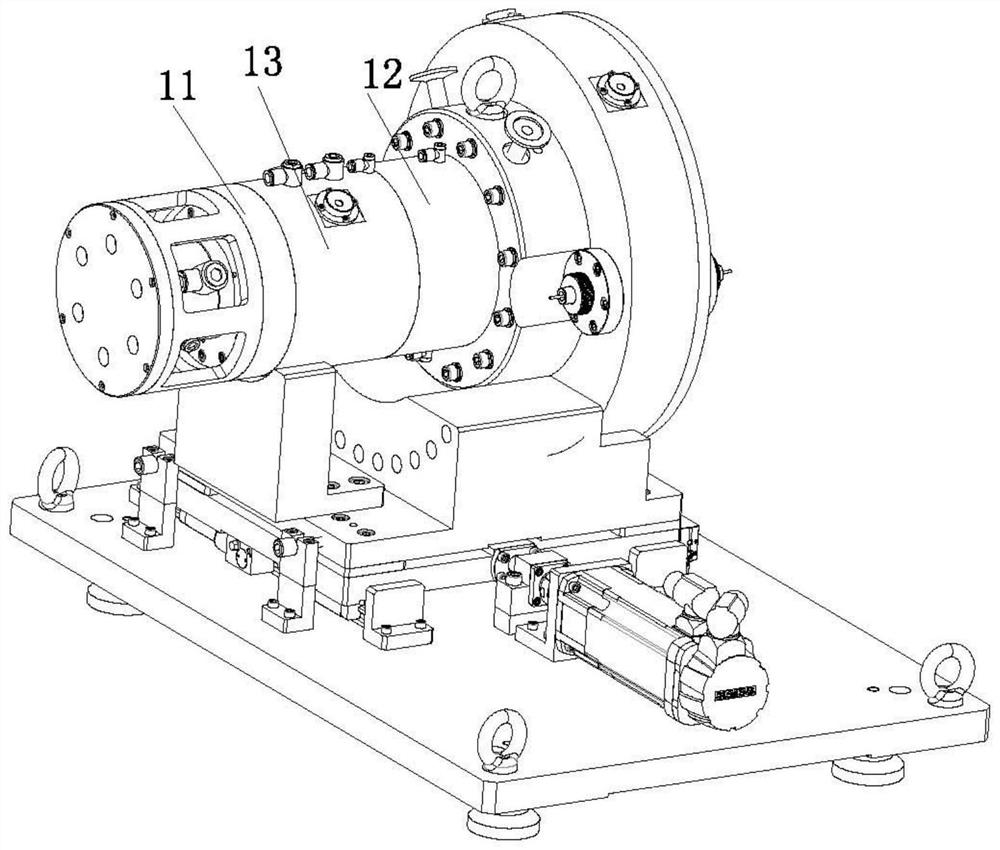

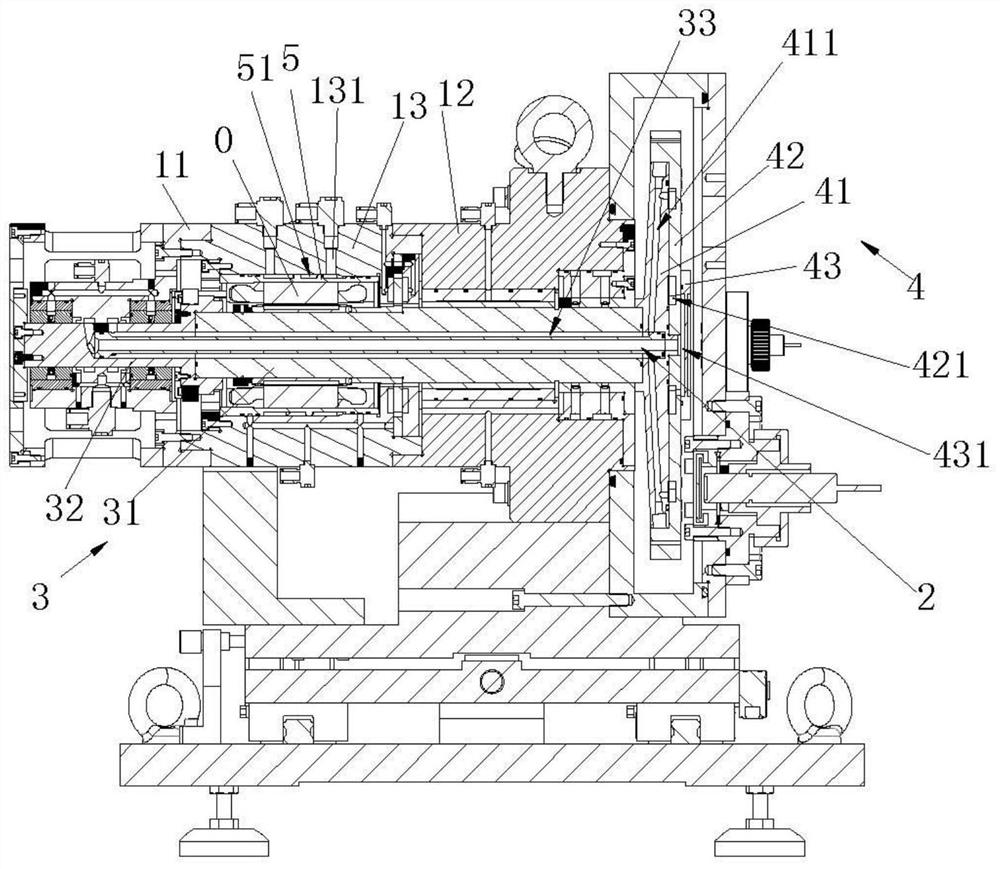

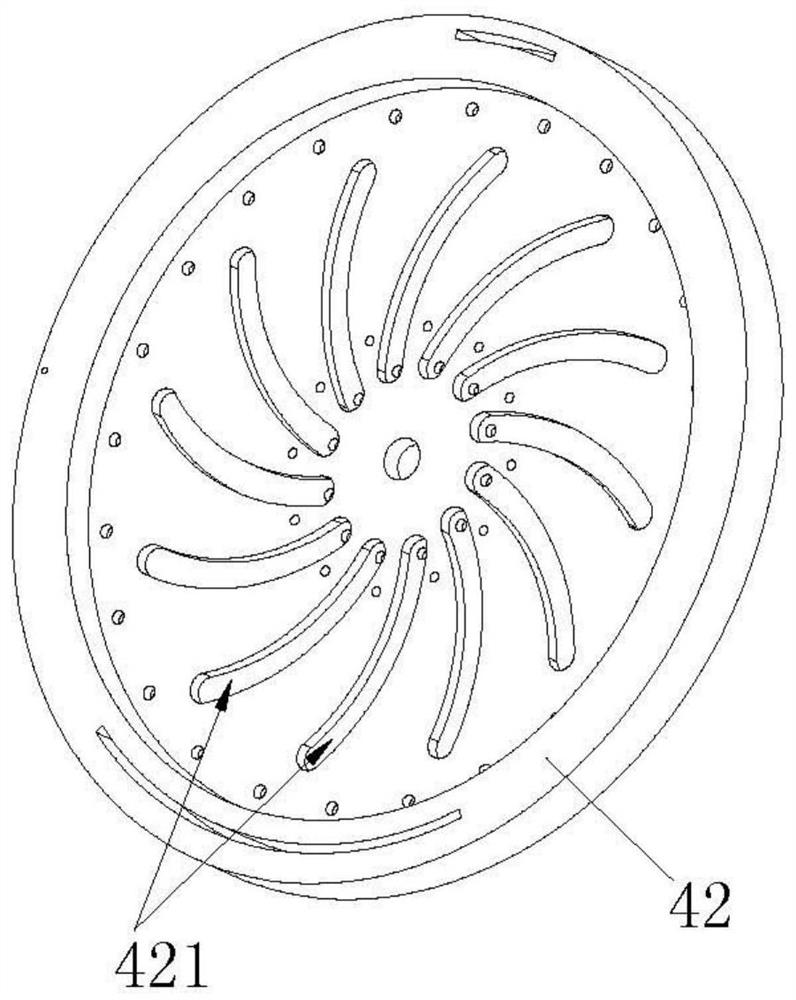

[0028] Such as Figure 1-3 As shown, the heat load chopper water cooling cooling system of the present invention includes a main shaft part 3, an X-ray absorption backflow assembly 4, an air-water rotary joint and a cooling water inlet nozzle, the main shaft part 3 can be rotatably arranged, and the X-ray absorption backflow assembly 4 It is arranged at the head end of the main shaft part 3, and the X-ray absorption backflow assembly 4 is located in the vacuum chamber; the middle part of the main shaft part 3 is provided with an axially extending shaft body cooling channel, and the X-ray absorption backflow assembly 4 is provided with a radial cooling channel 411, The cooling water inlet nozzle is conductively connected with the radial cooling channel 411 via the shaft body cooling channel and the air-water rotary joint. The heat load chopper water-cooling cooling s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap