Double-primary coplanar multiphase linear permanent magnet synchronous motor

A permanent magnet synchronous motor, coplanar technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large deformation of secondary structure, poor stability of mover, low thrust density, etc., and achieve high output thrust and thrust High density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

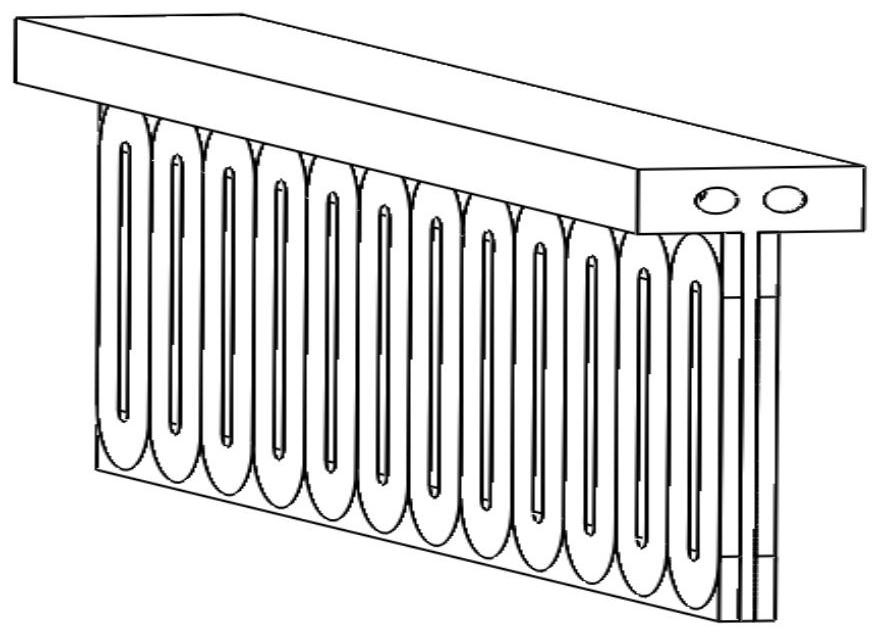

[0044] Specific implementation mode one: the following combination Figure 4-Figure 6 Describe this embodiment, a double-primary coplanar multi-phase linear permanent magnet synchronous motor described in this embodiment, which includes two primary, one secondary, a mover support mechanism and a base;

[0045] The primary includes a primary winding and a primary substrate on which the primary winding is disposed;

[0046] Secondary includes upper secondary, lower secondary and middle support plate;

[0047] The upper secondary includes an upper secondary yoke plate and an upper permanent magnet, and the upper permanent magnet is fixed on the lower side of the upper secondary yoke plate;

[0048] The lower stage includes a lower secondary yoke plate and a lower permanent magnet, and the lower permanent magnet is fixed on the upper side of the lower secondary yoke plate;

[0049] Both the upper permanent magnet and the lower permanent magnet include two arrays of permanent mag...

specific Embodiment approach 2

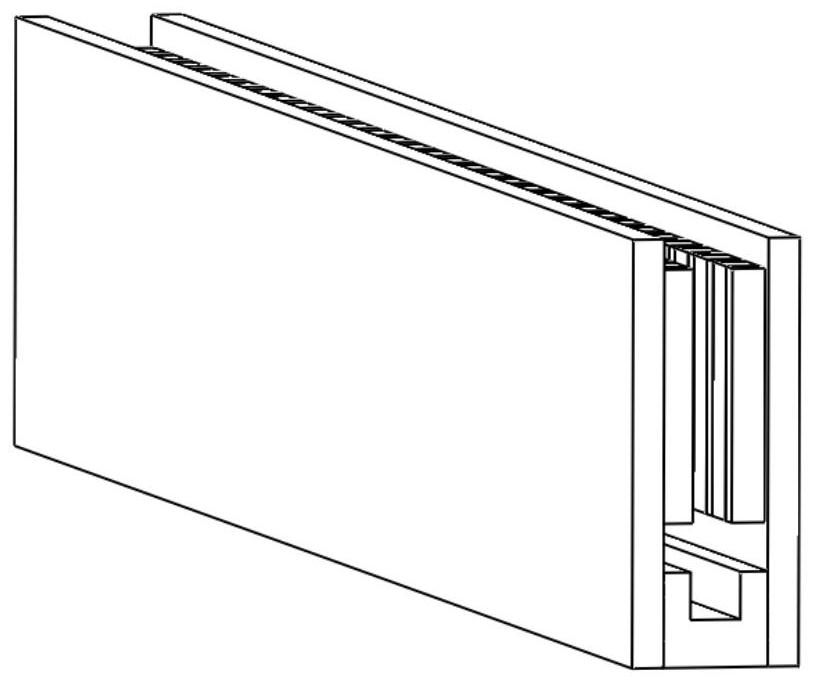

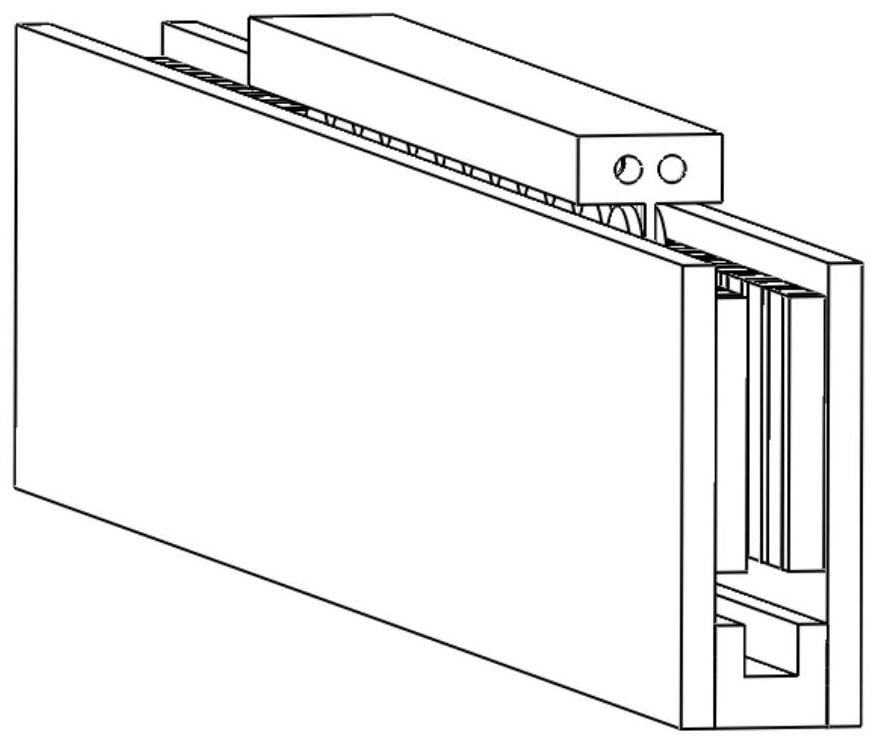

[0065] Specific implementation mode two: the following combination Figure 7-Figure 9 Describe this embodiment, another double-primary coplanar multi-phase linear permanent magnet synchronous motor described in this embodiment, which includes two primary, one secondary, mover support mechanism and base;

[0066] The primary includes a primary winding and a primary substrate on which the primary winding is arranged, and the primary substrates of the two primary are connected;

[0067] Secondary includes upper secondary, lower secondary and middle support plate;

[0068] The upper secondary includes an upper secondary yoke plate and an upper permanent magnet, and the upper permanent magnet is fixed on the lower side of the upper secondary yoke plate;

[0069] The lower sub-levels include symmetrically arranged lower left sub-levels and lower right sub-levels;

[0070] The lower left secondary includes the lower left yoke plate and the lower left permanent magnet, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com