A preparation and processing system of polycarboxylate water reducer

A processing system and water reducer technology, applied in the field of polycarboxylate water reducer preparation and processing systems, can solve the problems of difficult discharge, easy blocking of polycarboxylate water reducer filtration, polycarboxylate water reducer cannot be filtered, etc. , to achieve the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

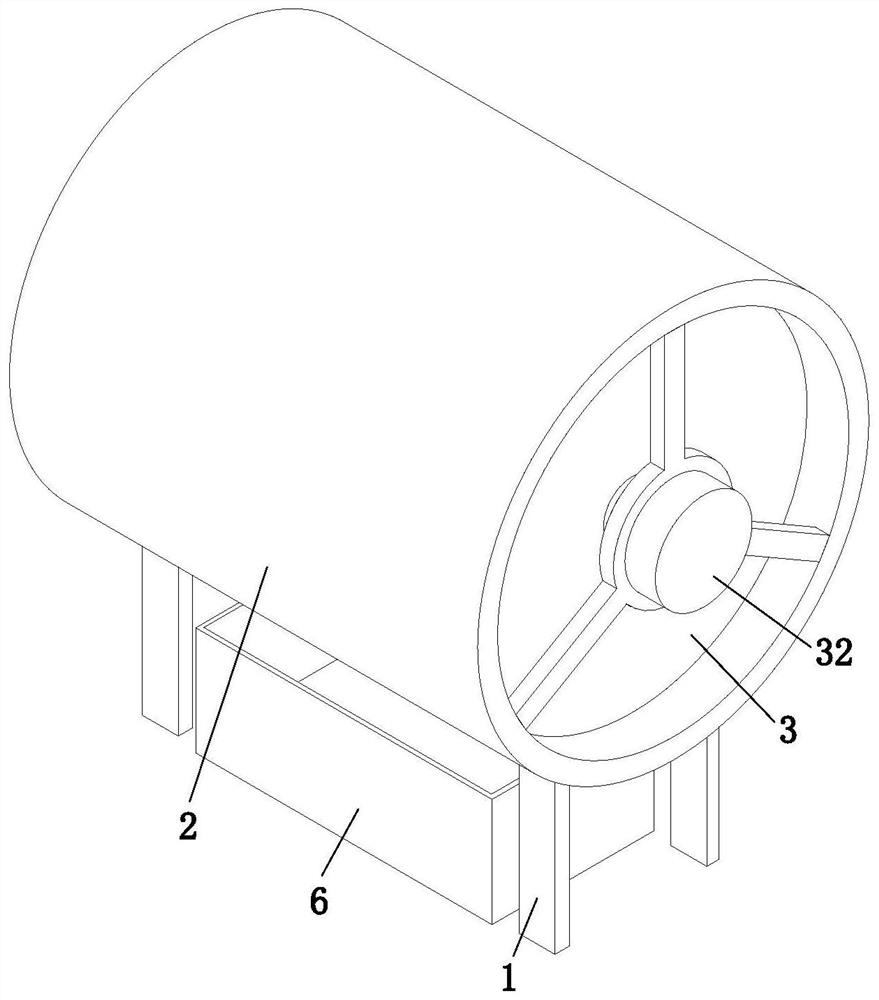

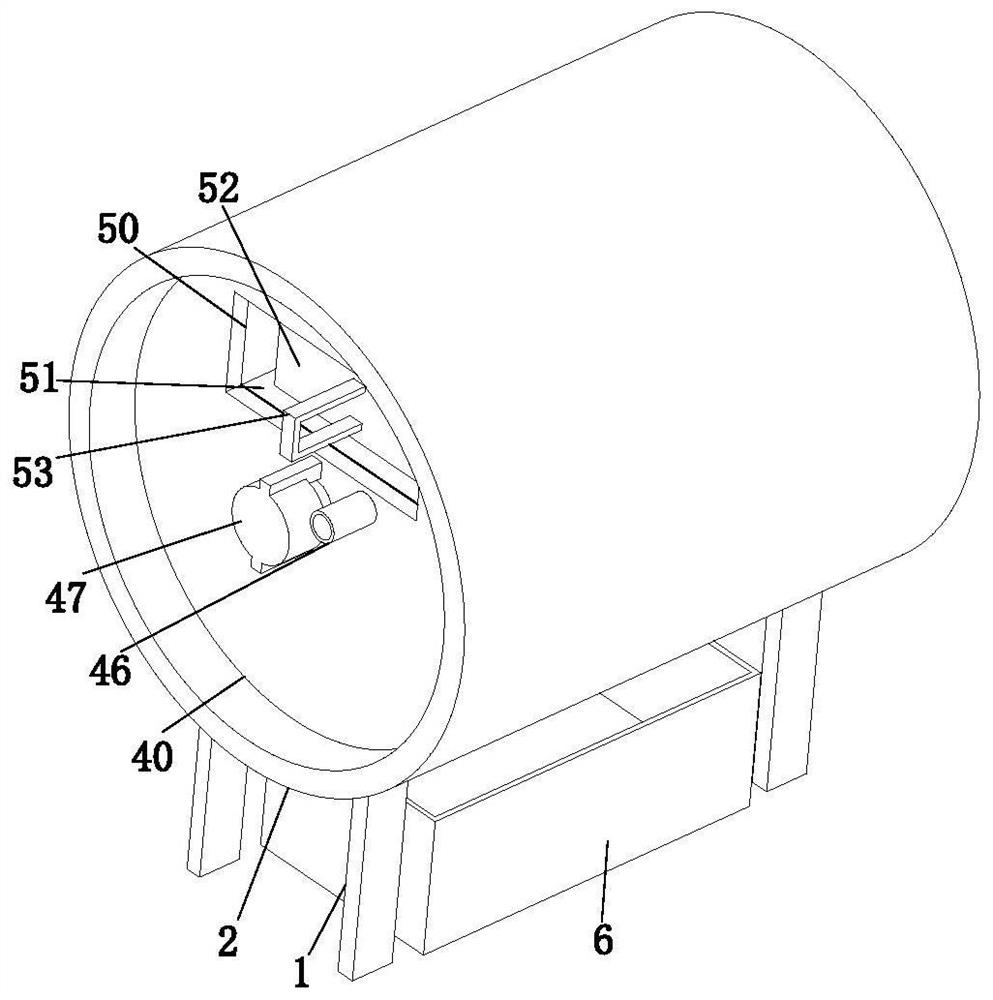

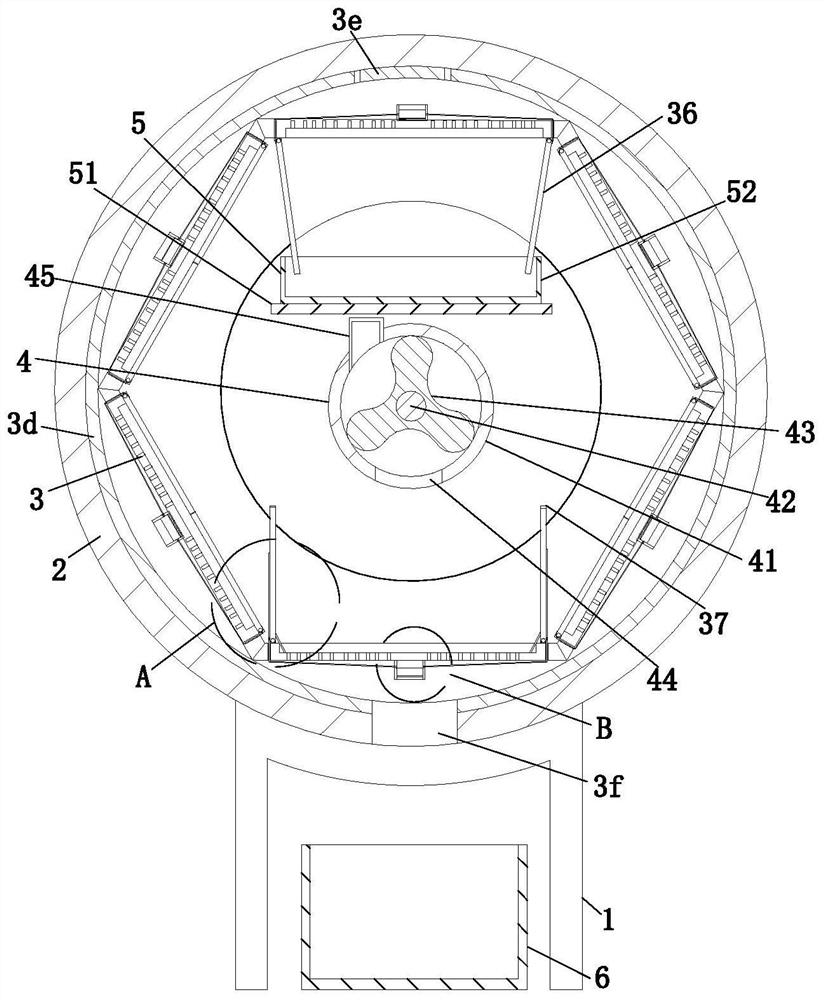

[0026] Such as Figure 1 to Figure 7 As shown, a polycarboxylate superplasticizer preparation and processing system includes a cylindric support frame 1, a preparation barrel 2, a filter mechanism 3, a feeding mechanism 4, a waste residue collection mechanism 5, and a polycarboxylate superplasticizer collection pool 6. The above-mentioned U-shaped support frame 1 is symmetrically arranged left and right. The U-shaped support frame 1 is a structure with an opening downward, and the horizontal section is an arc-shaped structure. The upper end surface of the U-shaped support frame 1 is equipped with a preparation bucket 2. End opening structure, the preparation tank 2 is provided with a filter mechanism 3, the filter mechanism 3 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com