Soil environment-friendly treatment and remediation equipment for environment-friendly engineering

A technology of environmental protection treatment and environmental protection engineering, applied in the direction of grain treatment, etc., can solve the problems of inductive treatment, difficult separation and adhesion of stones and soil, and achieve the effect of convenient inductive treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 To attach Figure 5 Shown:

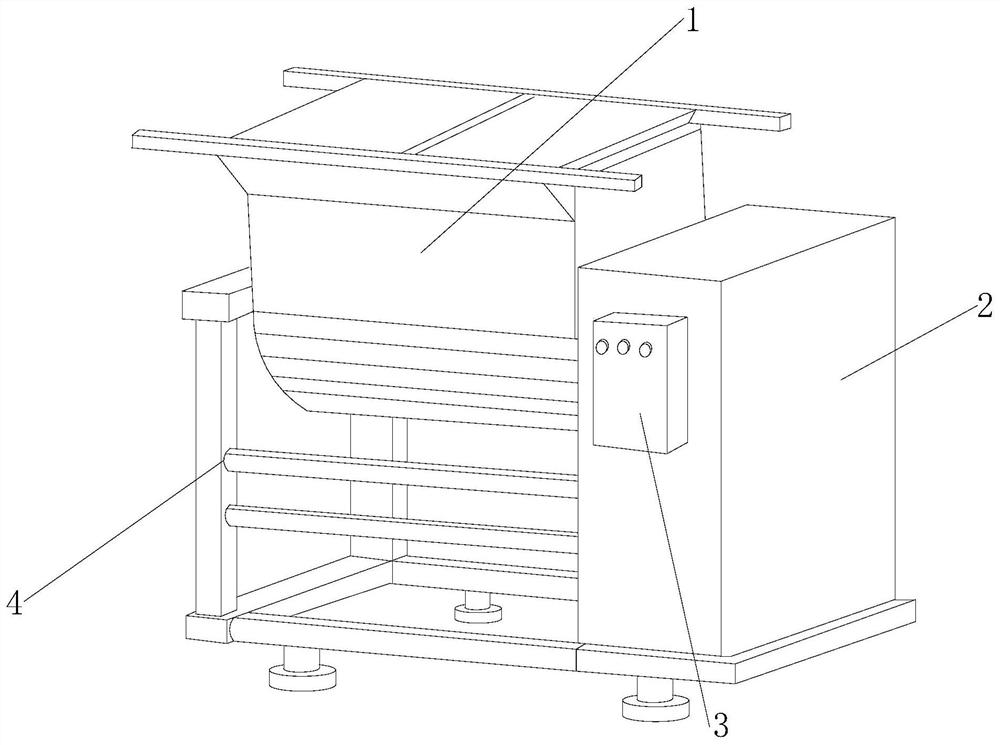

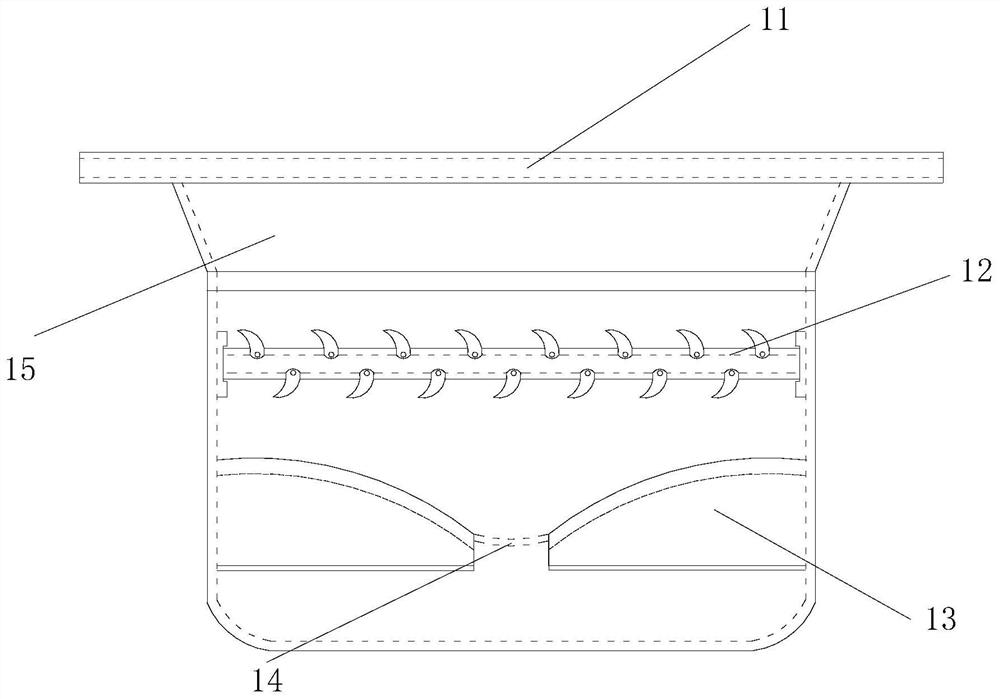

[0028] The invention provides a kind of soil environmental protection treatment and restoration equipment for environmental protection engineering. Its structure includes a crushing cabin 1, a control box 2, a button 3, and a chassis 4. The crushing cabin 1 is riveted and connected to the upper left side of the chassis 4. The control box 2 is movably engaged on the right side of the crushing cabin 1, and the button 3 is embedded and connected above the front end of the control box 2; the crushing cabin 1 is composed of a cross bar 11, a crushing knife 12, a separation device 13, and a drop point 14 , the cross bar 11 is embedded and connected to the top of 15, the left and right sides of the crushing knife 12 are embedded and connected to the upper inner side of 15, the separation device 13 is located directly below the crushing knife 12, and the falling part 14 is riveted and connected to Between the separation device...

Embodiment 2

[0035] as attached Figure 6 To attach Figure 8 Shown:

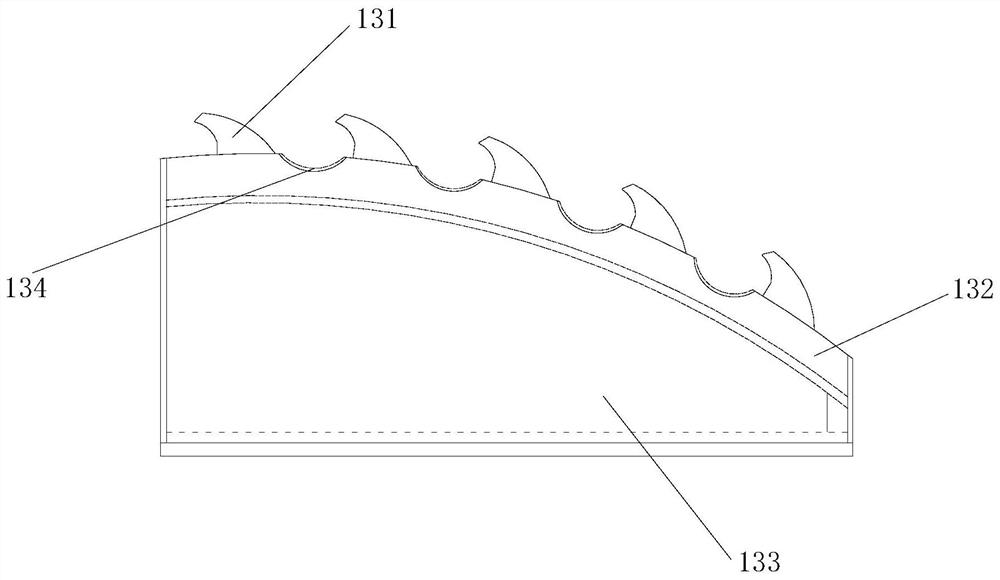

[0036] Wherein, the whereabouts 14 is composed of a corrugated ring 141, an outer ring 142, and a rotating piece 143. The corrugated ring 141 is movably engaged inside the outer ring 142, and the outer ring 142 is located outside the rotating piece 143. The rotating piece 143 is arranged on the inner side of the corrugated ring 141, and the surface of the corrugated ring 141 is corrugated and is arranged on the outer side of the rotating piece 143 and is relatively hard at the same time, so that when the stone falls, it is convenient to cooperate with the rotating piece 143 to rotate the stone to roll and help to peel off the outer surface of the stone. soil.

[0037]Wherein, the rotating piece 143 is composed of a rolling ring 431, a toggle piece 432, a control plate 433, and a rotating shaft 434. The upper and lower ends, the rotating shaft 434 is movably engaged in the middle part of the inner side of the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com