Automatic calibration, centering and bush press-fitting device for automobile torsion beam

An automatic calibration and press-fitting device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient bushing press-fitting and only one-sided press-fitting of bushings, etc., to achieve reliable press-fitting quality , The working environment is quiet and stable, and the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

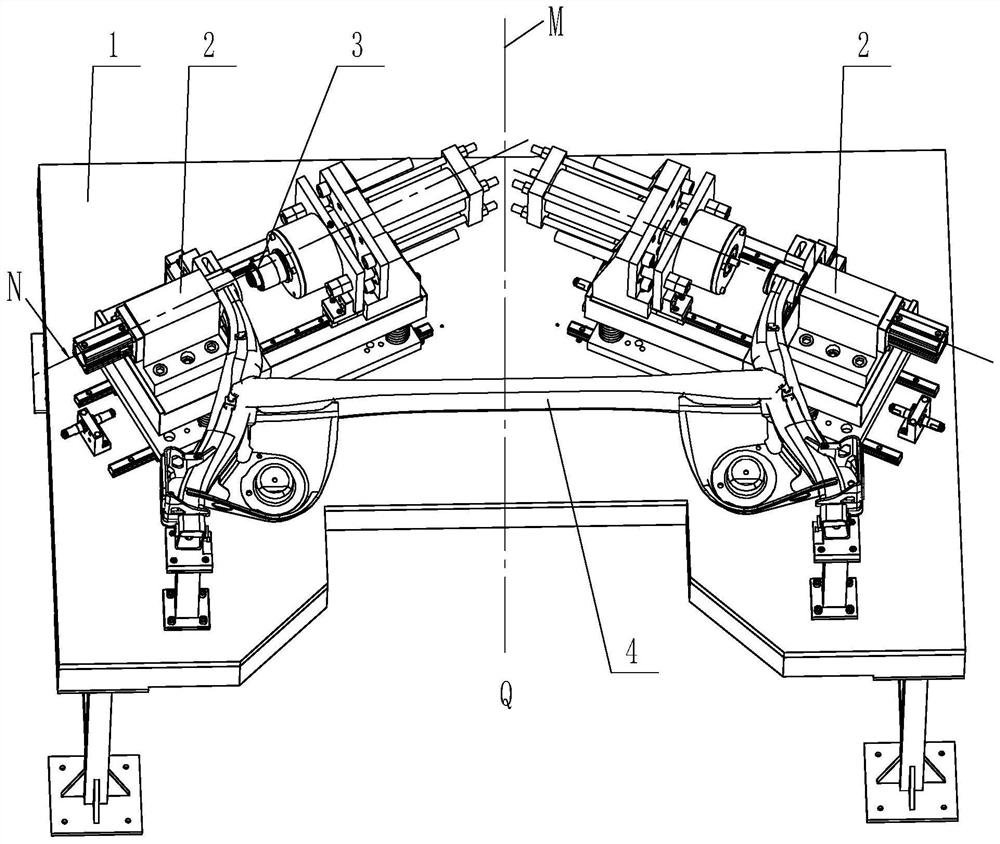

[0086] An automobile torsion beam automatic calibration centering press-fit bushing device (see figure 1 ), including a base device 1 and two sets of press-fitting devices 2 installed on the base device 1 in a figure-eight shape symmetrically left and right, wherein;

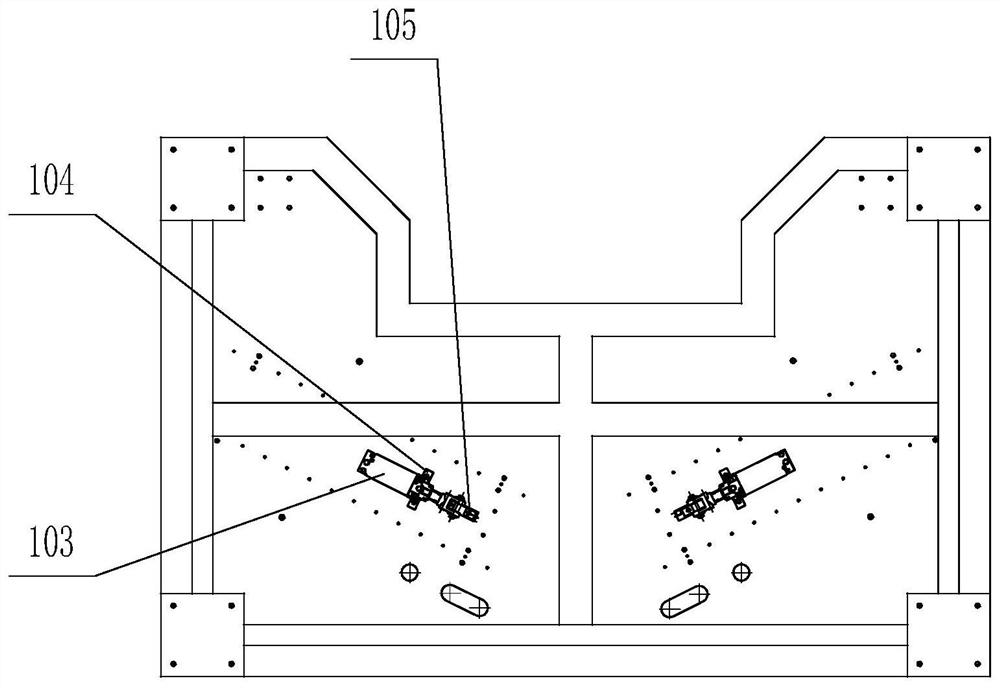

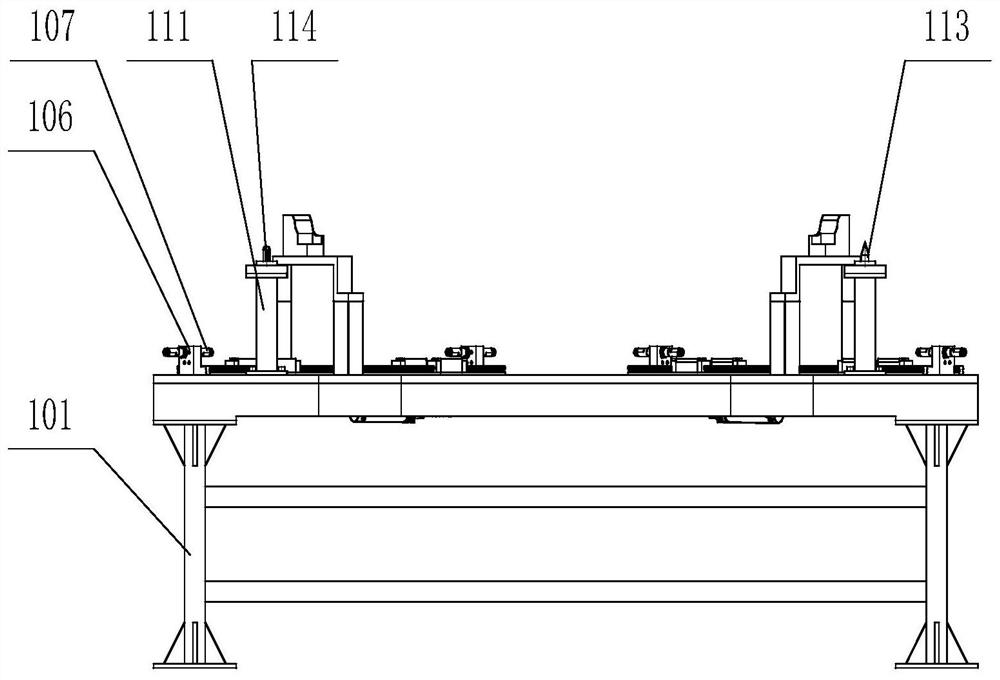

[0087] Two parallel guide rails 110 and a positioning device 11 for positioning the torsion beam are installed symmetrically on the left and right sides of the base device 1; 104, connection block 105, sensor mounting support 106, sensor 107 (see Figure 2 to Figure 5 ); the tripod 101 is installed on the bottom of the base plate 102, the base plate 102 is equipped with the guide rail I10 and the positioning device 11, and the base plate 102 is also provided with a connecting block avoidance groove 1021 (see Figure 6 ), the length of the connecting block avoidance groove 1021 is greater than the stroke of the first oil cylinder 103; the first oil cylinder bracket 104 is installed under the bottom plate 102, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com