Automatic press-fitting system and assembling method for ball screw pair bearings

A ball screw pair and screw pair technology, applied in the field of automatic assembly, can solve the problems of poor consistency of installation accuracy, improper installation of bearings, and small force-bearing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

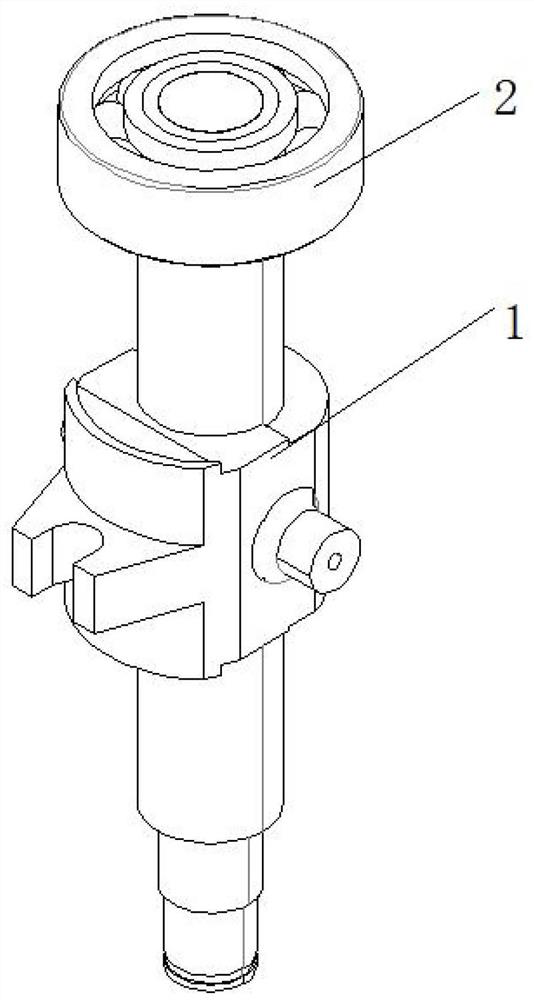

[0047] Such as figure 1 As shown, the end of the ball screw pair 1 needs to be installed with the bearing 2, and the screw end of the ball screw pair and the bearing 2 are installed in an interference fit manner. The automatic press-fitting system of the bearing of the ball screw pair of the present invention is used to realize the automatic press-fitting of the bearing on the ball screw pair 1 .

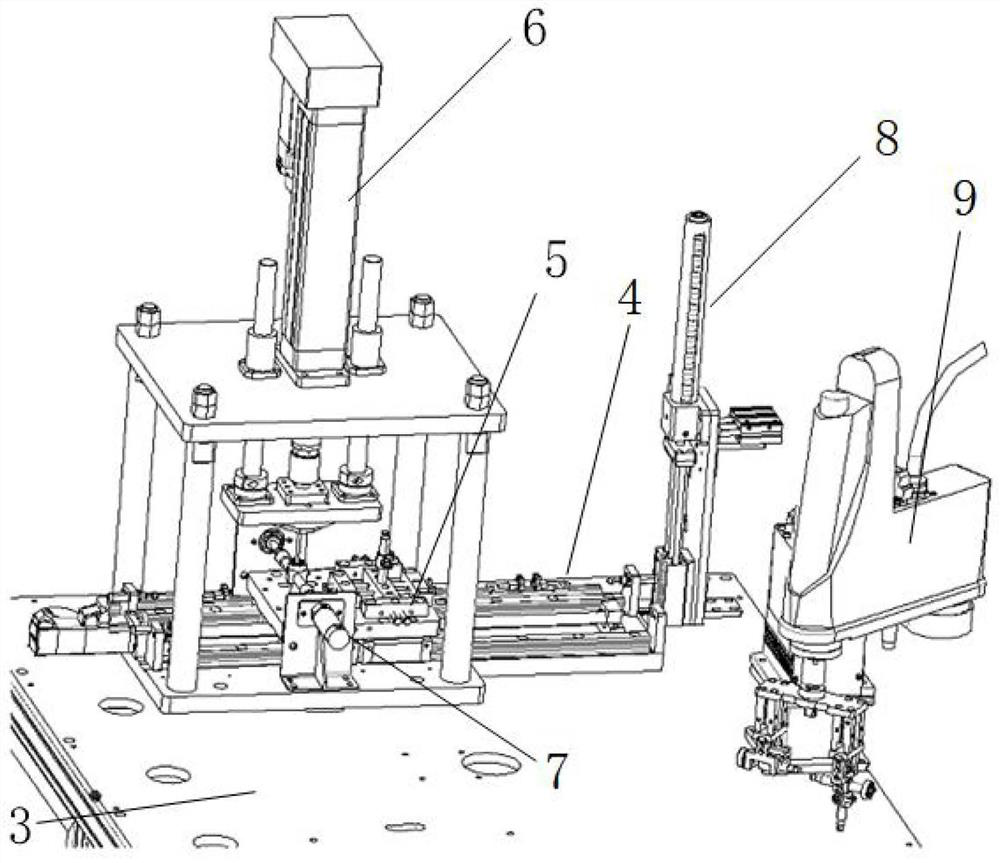

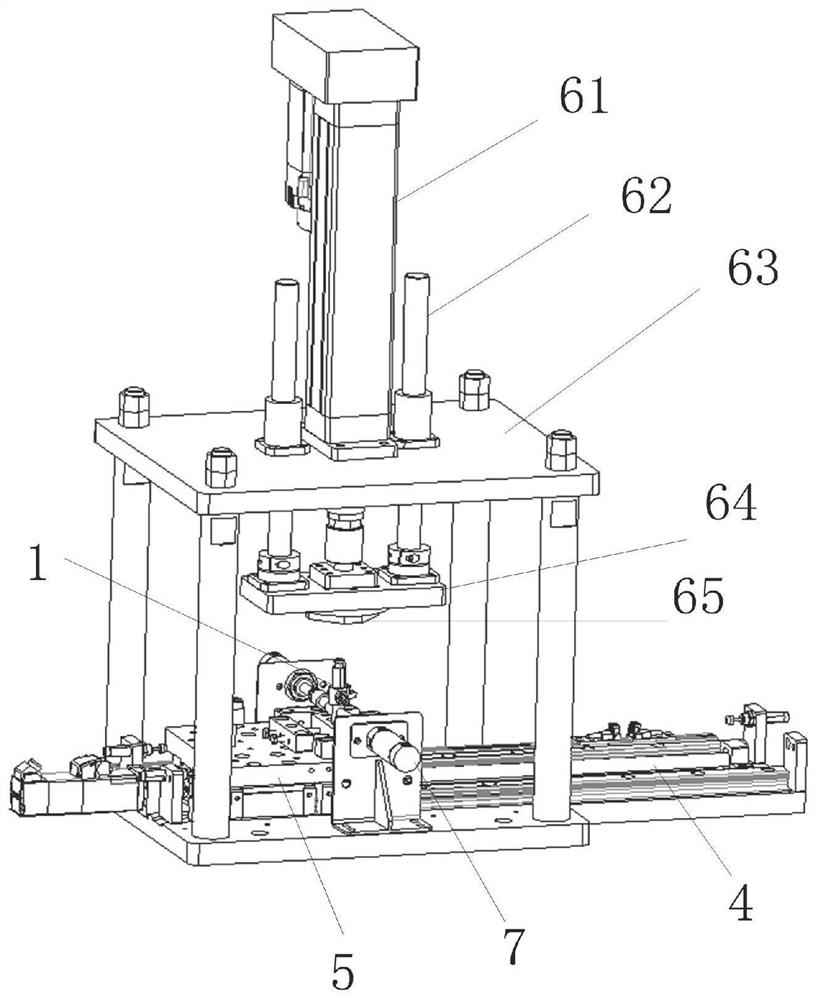

[0048] A specific embodiment of the present invention discloses an automatic press-fitting system for a ball screw sub-bearing, including: a slide rail mechanism 4 , a sliding fixture 5 , a press-fitting mechanism 6 and a screw sub-positioning mechanism 7 . Among them, the sliding fixture 5 is used for loading and positioning the bearing 2 and the ball screw pair 1, the sliding fixture 5 is arranged on the slide rail mechanism 4, and can be driven to slide through the slide rail mechanism 4; the press-fitting mechanism 6 is erected on the slide rail mechanism 4; the press-fit mecha...

Embodiment 2

[0080] A specific embodiment of the present invention provides an automatic press-fit assembly method for a ball screw pair bearing. The ball screw pair 1 and bearing 2 are assembled using the ball screw pair bearing automatic press-fit system in Embodiment 1, including The following steps:

[0081] Step S1: drive the sliding fixture 5 to slide to the first station along the linear guide rail 41; place the ball screw pair 1 on the screw pair positioning block 53 of the sliding fixture 5; take out a bearing 2 from the bearing bin 8, And place the bearing 2 on the bearing positioning pin 52 of the sliding fixture 5;

[0082] Step S2: Drive the sliding fixture 5 to slide to the second station along the linear guide rail 41, so that the bearing positioning pin 52 is axially aligned with the magnetic indenter 65 of the press-fitting mechanism 6; the press-fitting mechanism 6 drives the magnetic indenter 65 to move down, Adsorb the bearing 2 on the bearing positioning pin 52;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com