Connecting device used between airport trailers

A connecting device and workshop technology, which is applied in the direction of equipment for transporting goods, traction connectors, vehicle parts, etc., can solve the problem that the towing pin does not have automatic spring-off and locking, it is inconvenient to automatically lock and prevent falling, and the work efficiency is low and other issues to achieve the effect of improving fixing efficiency, facilitating use and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

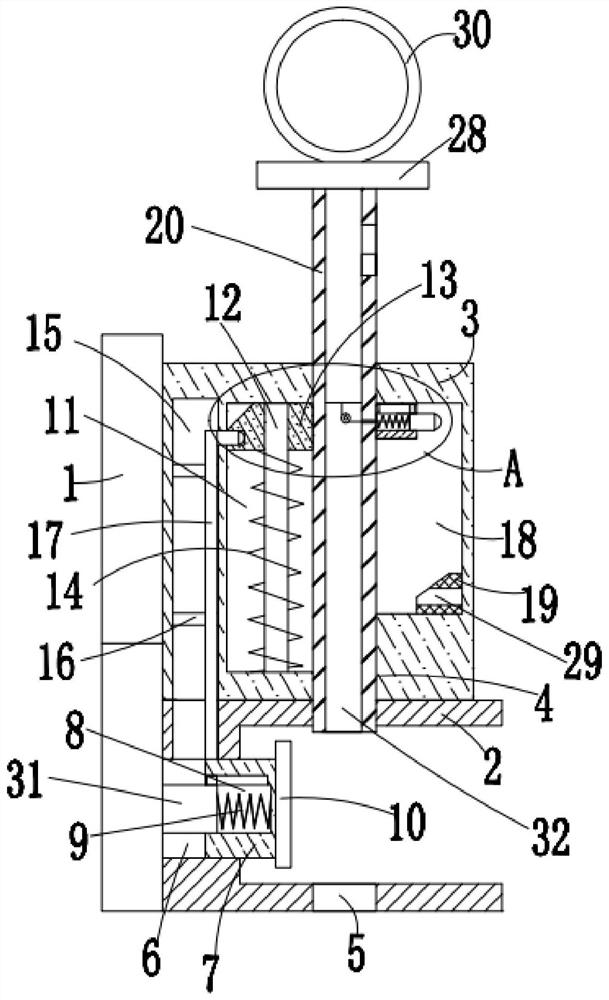

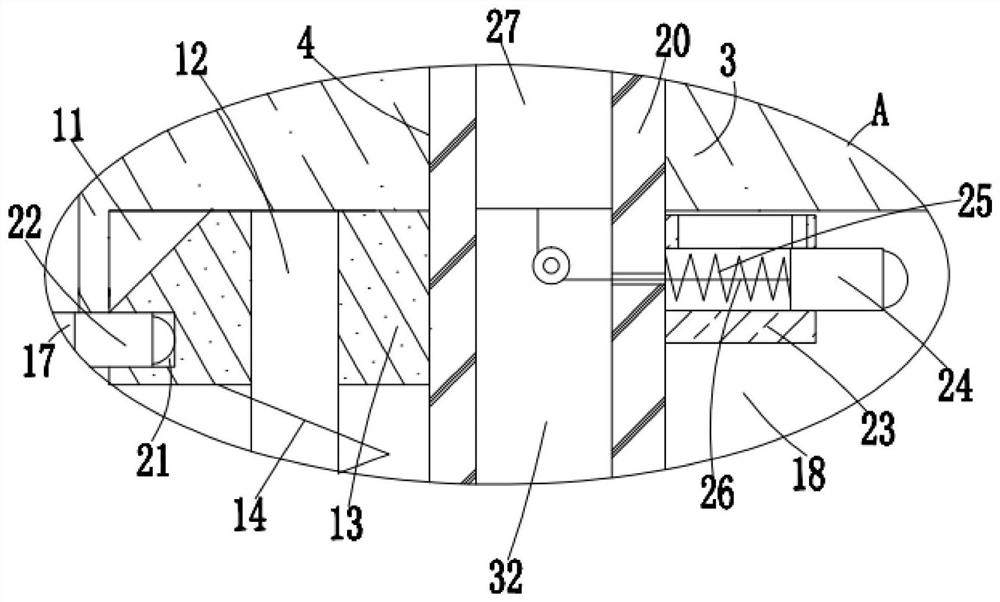

[0026] refer to Figure 1-5 , this embodiment proposes a connection device for airport trailer workshops, including a T-shaped mounting base 1, a U-shaped mounting base 2 is fixedly connected to the right side of the T-shaped mounting base 1, and the top of the U-shaped mounting base 2 is fixedly connected to There is a mounting block 3, the right side of the T-shaped fixed seat 1 is provided with a towing pin 20, the top of the mounting block 3 is provided with a circular hole 4, and the towing pin 20 is slidingly sleeved in the circular hole 4, and the towing pin 20 The bottom end of the U-shaped installation seat 2 extends into the U-shaped installation seat 2, and the inner wall of the bottom of the U-shaped installation seat 2 is provided with a socket 5, and the towing pin 20 is matched with the socket 5. Coordinated automatic pop-up insertion mechanism and automatic locking mechanism;

[0027]The automatic pop-up insertion mechanism includes a first rectangular hole 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com