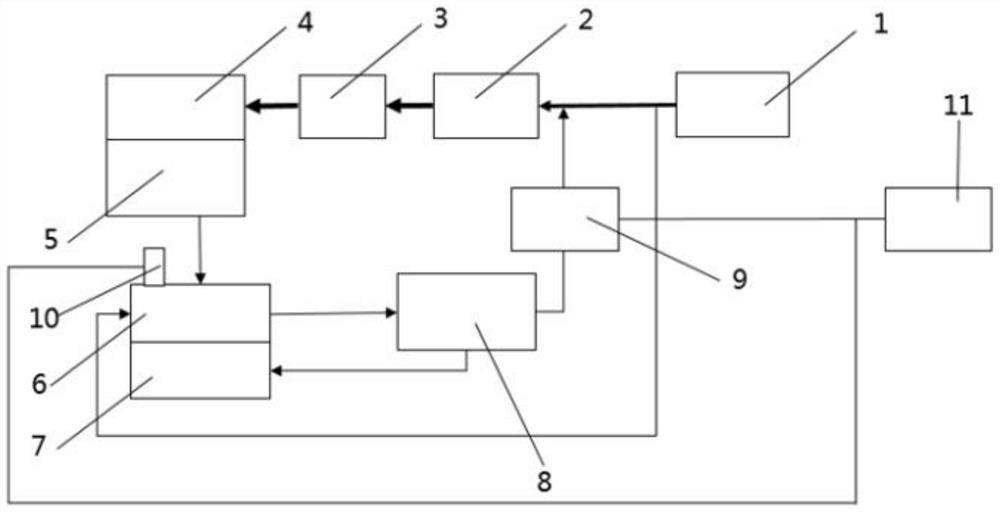

Active two-stroke engine crankcase ventilation system

A crankcase ventilation and engine technology, which is applied to crankcase ventilation, engine components, machines/engines, etc., can solve the problems that the engine crankcase does not meet the requirements of regulations, and achieve the effect of slowing down oxidation and deterioration and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In cold weather, the temperature inside the crankcase 6 is low, and water vapor condensation is likely to cause oil emulsification, but the use of the suction pump 9 can quickly pump out the mixed steam in the crankcase 6 to reduce the concentration, thereby reducing water vapor condensation and preventing oil emulsification and icing in the flex tube.

Embodiment 2

[0028] Part of the unburned mixture leaked through the piston ring in the crankcase 6 re-enters the intake port through the suction of the suction pump 9, and then enters the combustion chamber 5 for combustion, which can further improve the efficiency of the engine.

Embodiment 3

[0030] By controlling the suction pump 9 to create a negative pressure source, the mixture in the crankcase 6 is sucked into the intake passage, so that the pressure in the crankcase 6 is always controlled at a negative pressure state of -6~+3kPa, which meets the regulations requirements.

[0031] This technology solves the risk problem that the crankcase ventilation system of a DC scavenging two-stroke engine does not meet the requirements of emission regulations, and at the same time can accelerate the ventilation effect of crankcase pollutants and fresh air, and slow down the oxidation and deterioration of engine oil;

[0032] The present invention can utilize the pumping effect of the air pump 9, which is equivalent to forming a negative pressure source outside, and the mixed gas in the crankcase 6 re-enters the air inlet after oil-gas separation and then enters the combustion chamber 5 for combustion, thereby improving the crankcase 6. At the same time, after the mixed ga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap