Conical surface inner diameter measuring instrument and measuring method thereof

A measuring instrument and inner diameter technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of complex structure of parts, difficult measurement of general measuring tools, and only deep holes can be measured, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

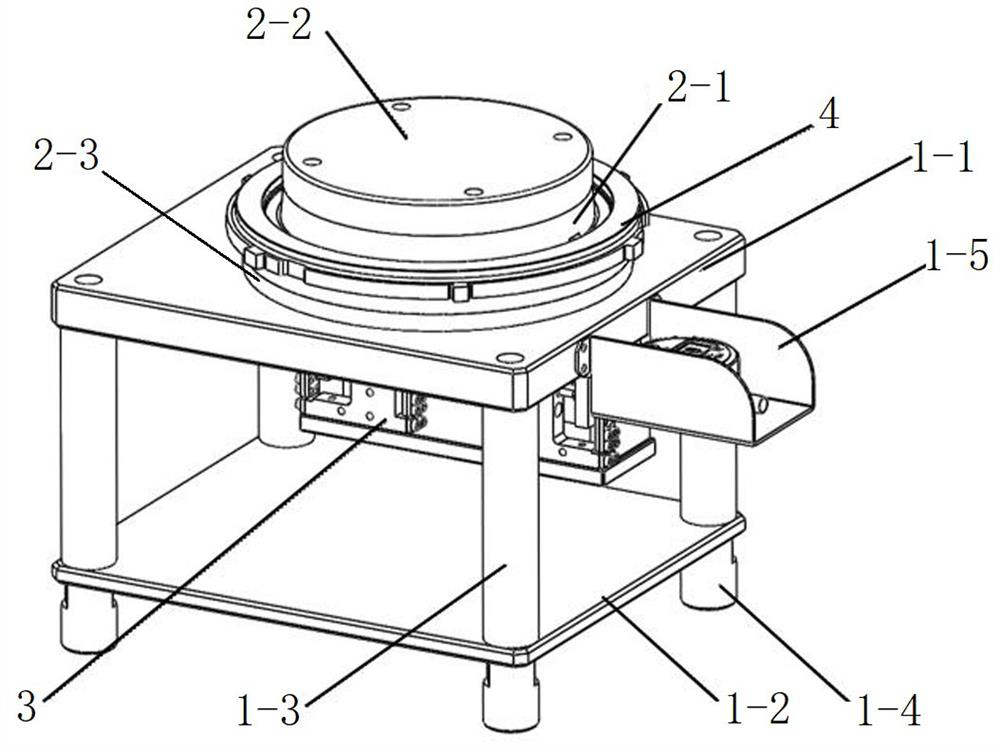

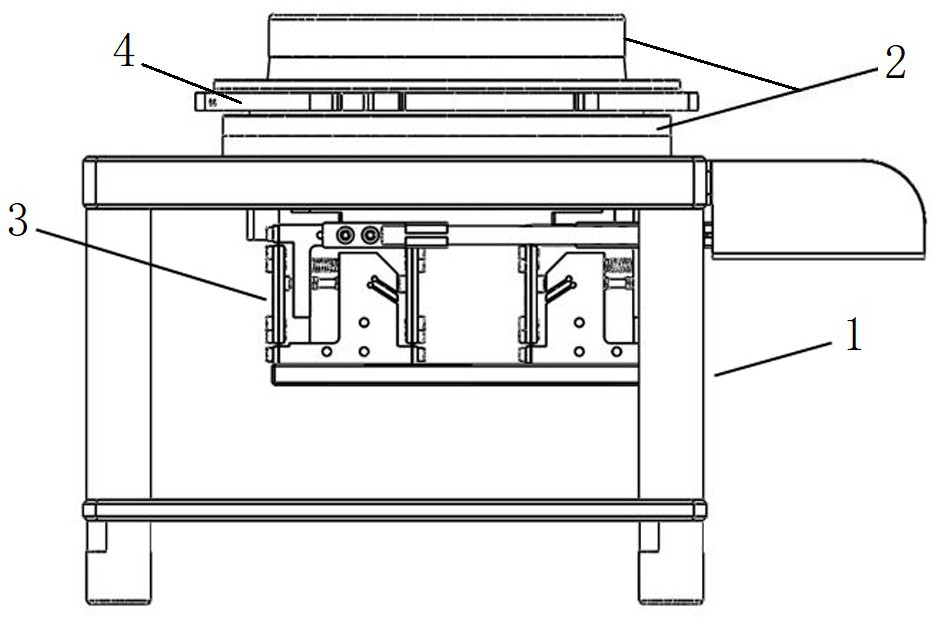

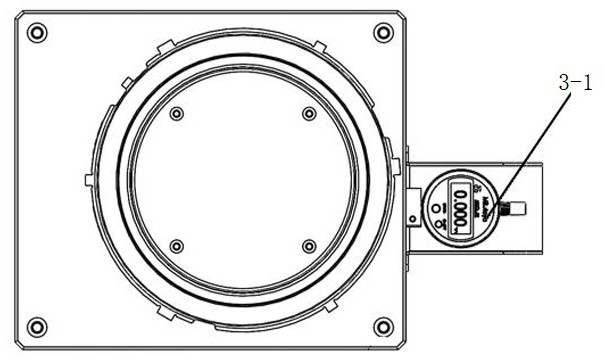

[0032] Such as Figure 1-12As shown, a cone inner diameter measuring instrument of the present invention includes a support base 1, a guide 2 and an inner diameter detection unit 3, and the support base 1 includes an upper orifice plate 1-1, a bottom plate 1-2, a column 1-3 and The ground feet 1-4, the upper orifice plate 1-1 and the bottom plate 1-2 are fixedly connected by four columns 1-3, and the four columns 1-3 are symmetrically installed on the four corners of the upper orifice plate 1-1 and the bottom plate 1-2 , the anchor 1-4 is fixedly installed at the four corners of the bottom surface of the bottom plate 1-2, the guide 2 includes a guide sleeve 2-1, a guide sleeve cover 2-2 and a positioning platform 2-3, and the positioning platform 2-3 is a hollow platform , the positioning table 2-3 is fixed on the upper orifice plate 1-1, and the inner hole of the positioning table 2-3 is aligned with the inner hole of the upper orifice plate 1-1, and the guide sleeve 2-1 is s...

Embodiment 2

[0034] Taking the cone inner diameter measuring instrument of embodiment 1 as an example, the measuring method of the cone inner diameter measuring instrument comprises the following steps:

[0035] S1. Zero correction of the cone surface standard part: the cone surface standard part is pierced with the guide sleeve 2-1 and supported on the positioning platform 2-3, and the two probes 3-21 are in contact with the surface of the inner hole of the cone surface standard part through displacement deformation. The displacement and deformation of the two probes 3-21 are transmitted to the T-shaped moving block 3-22 through the connecting rod 3-23, and the T-shaped moving block 3-22 is transmitted to the inner leaf spring unit and the outer leaf spring unit through the screw 3-42. The leaf spring unit and the outer leaf spring unit pass the displacement feedback to the T-shaped moving block 3-22 through the deformation of the leaf spring 3-45, and the left T-shaped moving block 3-22 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com