Conductive plastic sensor

A conductive plastic and sensor technology, applied to instruments, electrical devices, electromagnetic means, etc., can solve the problems of overheating of conductive plastic sensors, easy to be bumped by external force, and no appearance protection of conductive plastic sensors, so as to be easy to connect and place. , the effect of increasing or decreasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

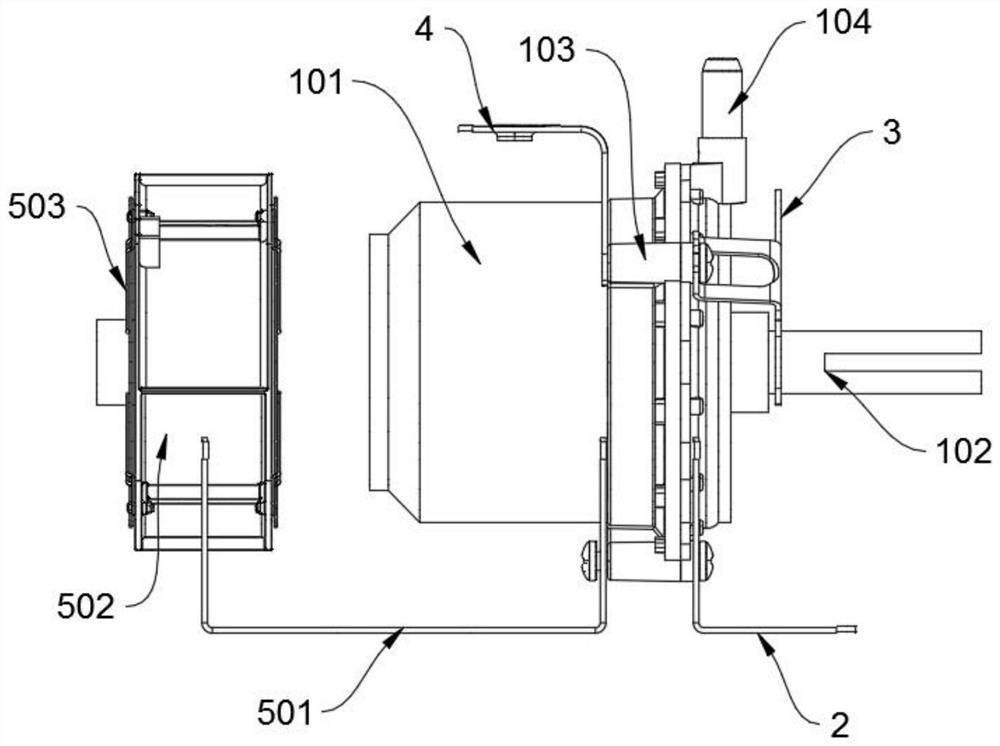

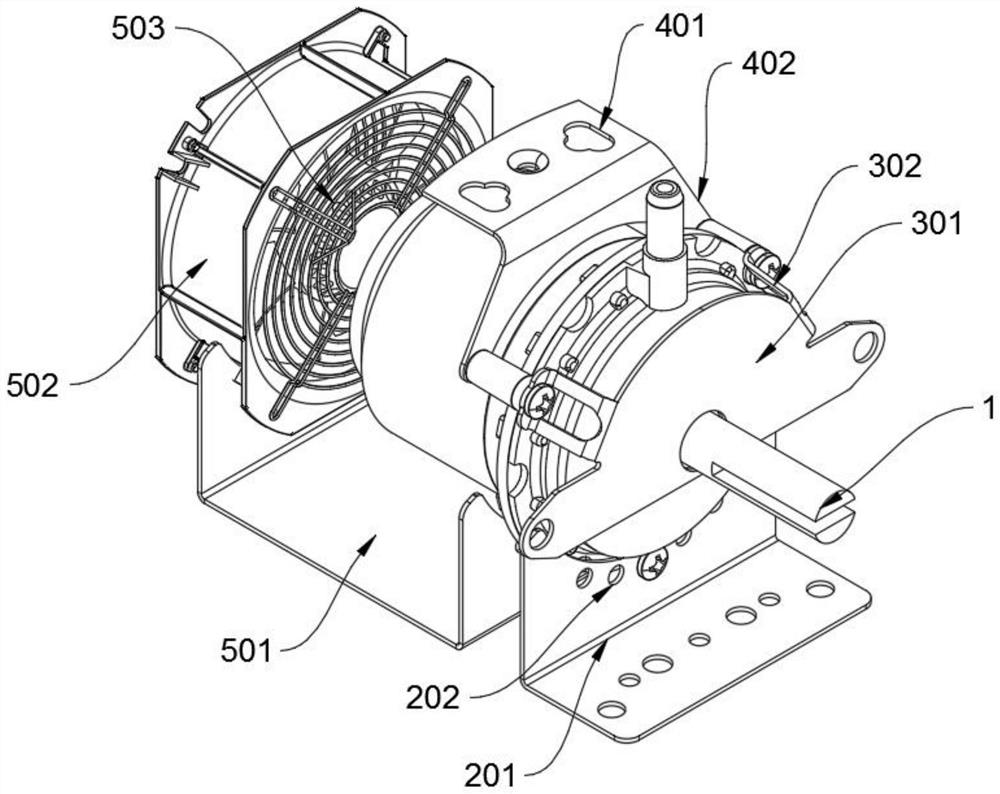

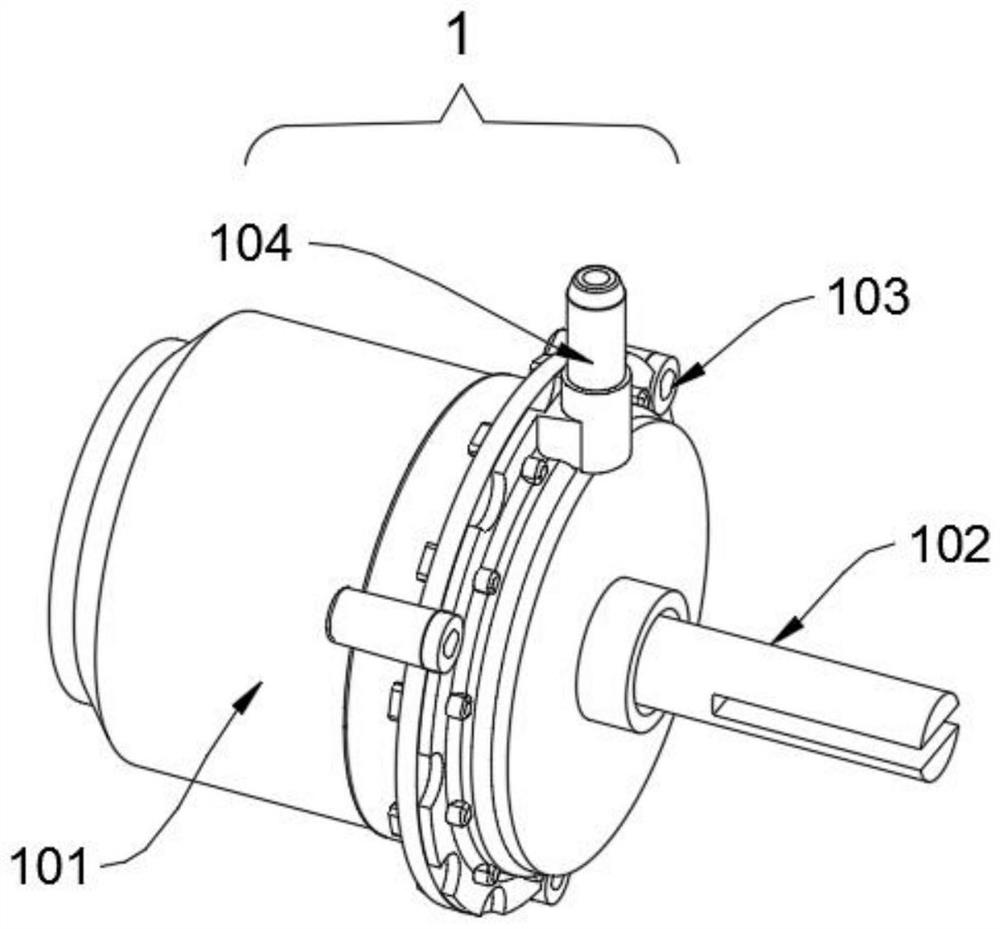

[0028] as attached figure 1 to attach Image 6 Shown:

[0029] The invention provides a conductive plastic sensor, comprising: a device main body 1, a front stop mechanism 3, an upper connection mechanism 4 and a rear connection mechanism 5, the position below the front end of the device main body 1 is fixedly connected to the rear end of the front connection mechanism 2; the front stop mechanism 3 is fixedly connected to the front end of the device main body 1, and the front stop mechanism 3 is located above the front connecting mechanism 2; the upper connecting mechanism 4 is fixedly connected to the top position of the device main body 1; connected, and the rear connection mechanism 5 is located directly behind the front connection mechanism 2; the rear connection mechanism 5 includes a rear connection plate 501, a fan 502 and a guard net 503, the rear connection plate 501 is in the shape of a square, and the back end of the rear connection plate 501 It is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com