Direct drive motor structure and motor

A direct-drive motor and motor shaft technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electric components, etc., can solve permanent magnet motor torque ripple, speed fluctuation, cogging Large torque and other problems, to achieve the effect of easy connection and reduce cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

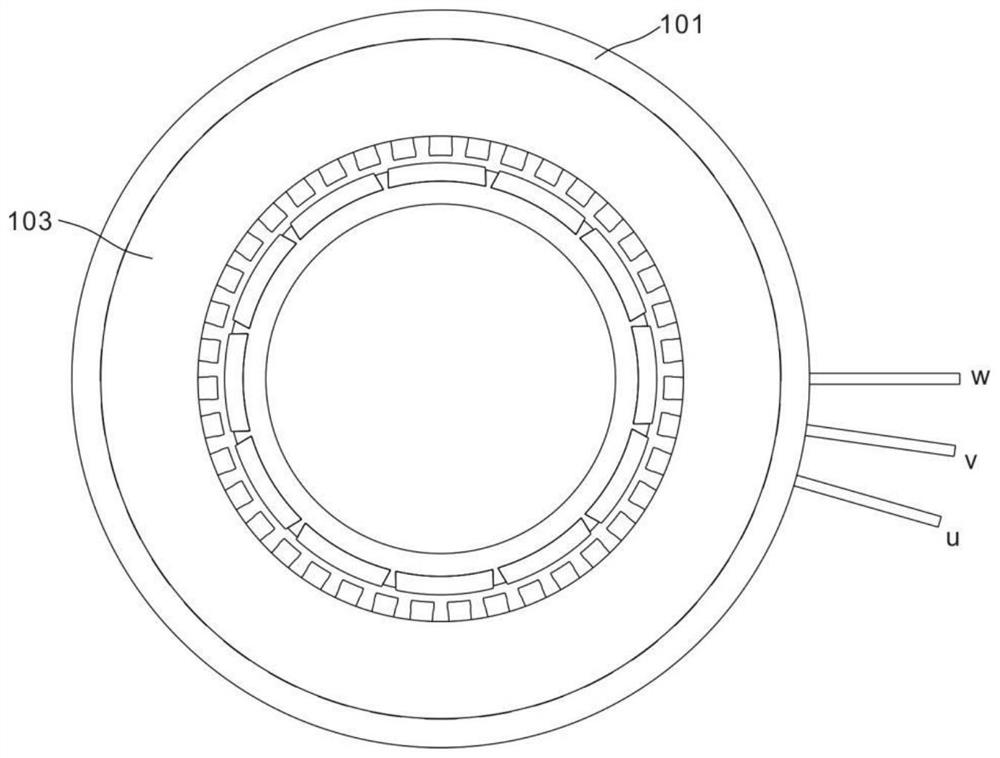

[0048] refer to Figure 1~5 , this embodiment provides a direct drive motor structure, including,

[0049] The stator component 100, the stator component 100 includes an outer ring 101 and a stator punching sheet 102 laminated in the outer ring 101;

[0050] The rotor component 200 , the rotor component 200 is disposed inside the stator component 100 , and the rotor component 200 includes a rotor core 201 and a magnetic steel 202 embedded outside the rotor core 201 .

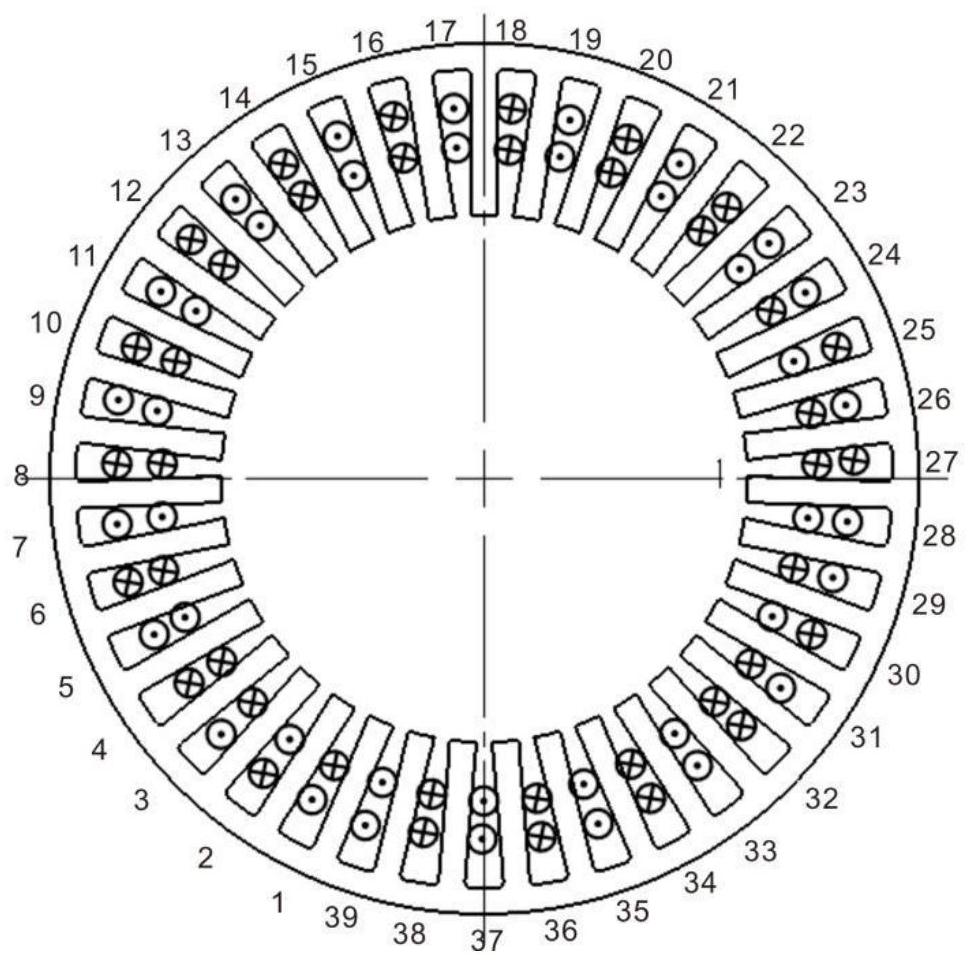

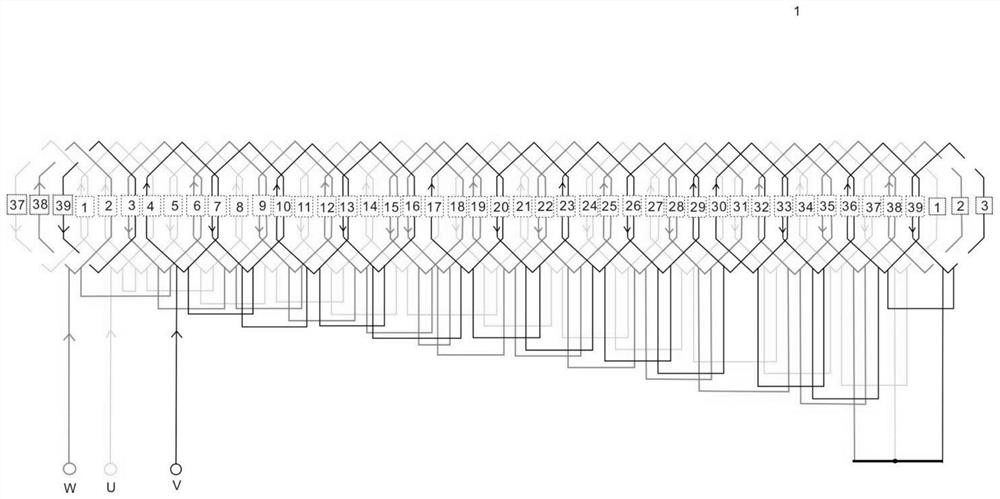

[0051] The stator stamping 102 includes a slot yoke 102a, stamping slots 102b and spacers 102c, and the stamping slots 102b and spacers 102c are arranged alternately inside the slot yoke 102a.

[0052]It should be noted that punching grooves 102b are provided on the groove yoke 102a, and spacers 102c are left between the punching grooves 102b to make the boundaries between the punching grooves 102c clear. The winding mode of the winding between the punching slots 102b is changed by taking the spacer bar 102c a...

Embodiment 2

[0069] refer to Figure 6-11 , this embodiment provides a direct-drive motor, including the above-mentioned structure of a direct-drive motor, and also includes,

[0070] A motor shaft 300, a ring sleeve 301 is fixed on the motor shaft 300, and an inner groove 302 is arranged between the ring sleeve 301 and the motor shaft 300;

[0071] A first through hole 303 is provided on the circumferential surface of the ring sleeve 301, a slot 304 is provided on the motor shaft 300, and the position of the first through hole 303 corresponds to the position of the slot 304;

[0072] The motor shaft 300 is disposed inside the rotor core 201 and connected to the rotor core 201 through a connector 400 .

[0073] The position of the first through hole 303 corresponds to the position of the slot 304 , which means that the projection positions of the first through hole 303 and the slot 304 coincide with each other along the axial direction of the motor shaft.

[0074] The plug connector 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com