Semiconductor processing apparatus having linear conveyor system

A technology of conveying system and processing device, applied in conveyor control device, semiconductor/solid-state device manufacturing, storage device, etc., can solve problems such as semiconductor device defect, failure, uneven copper layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

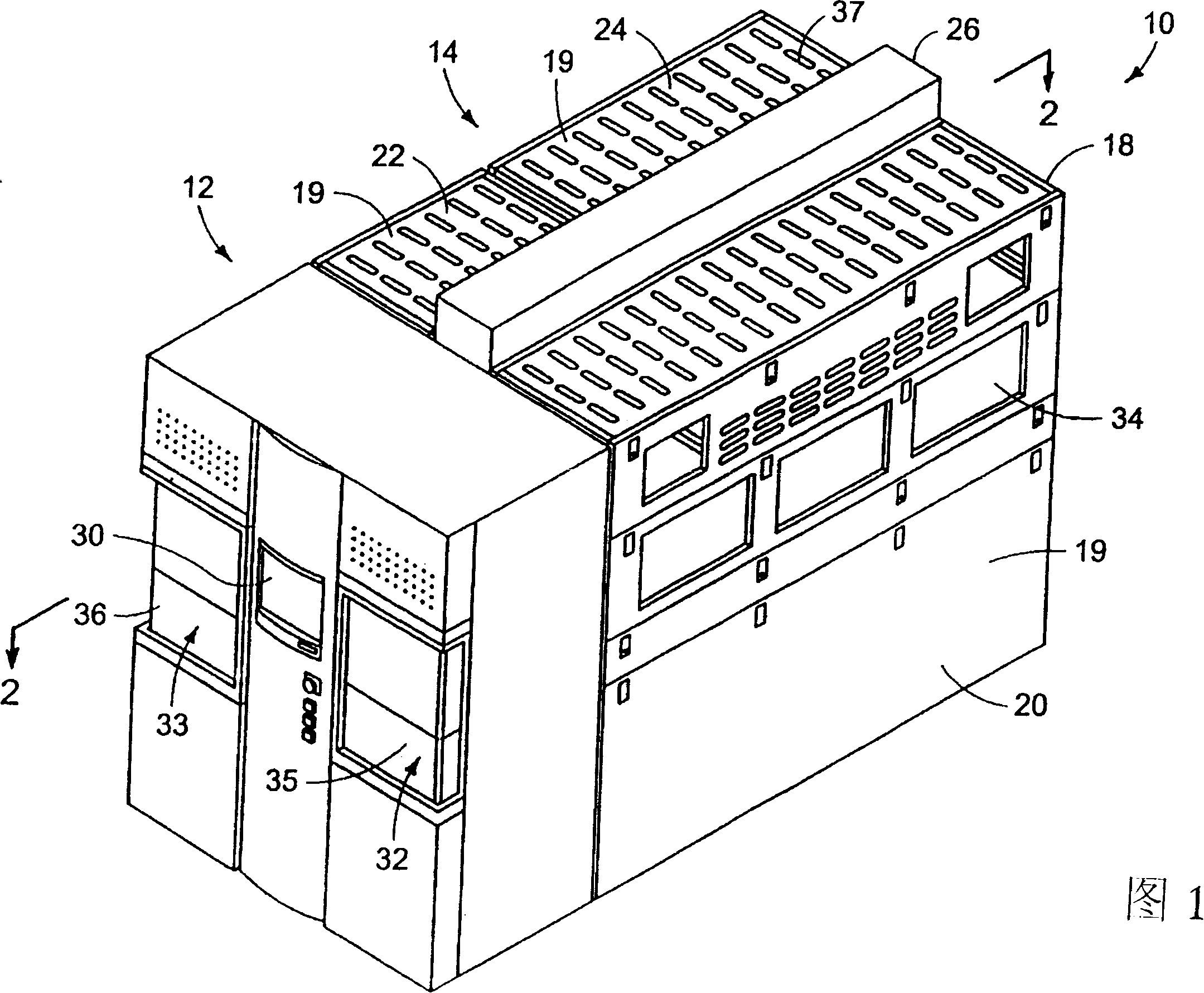

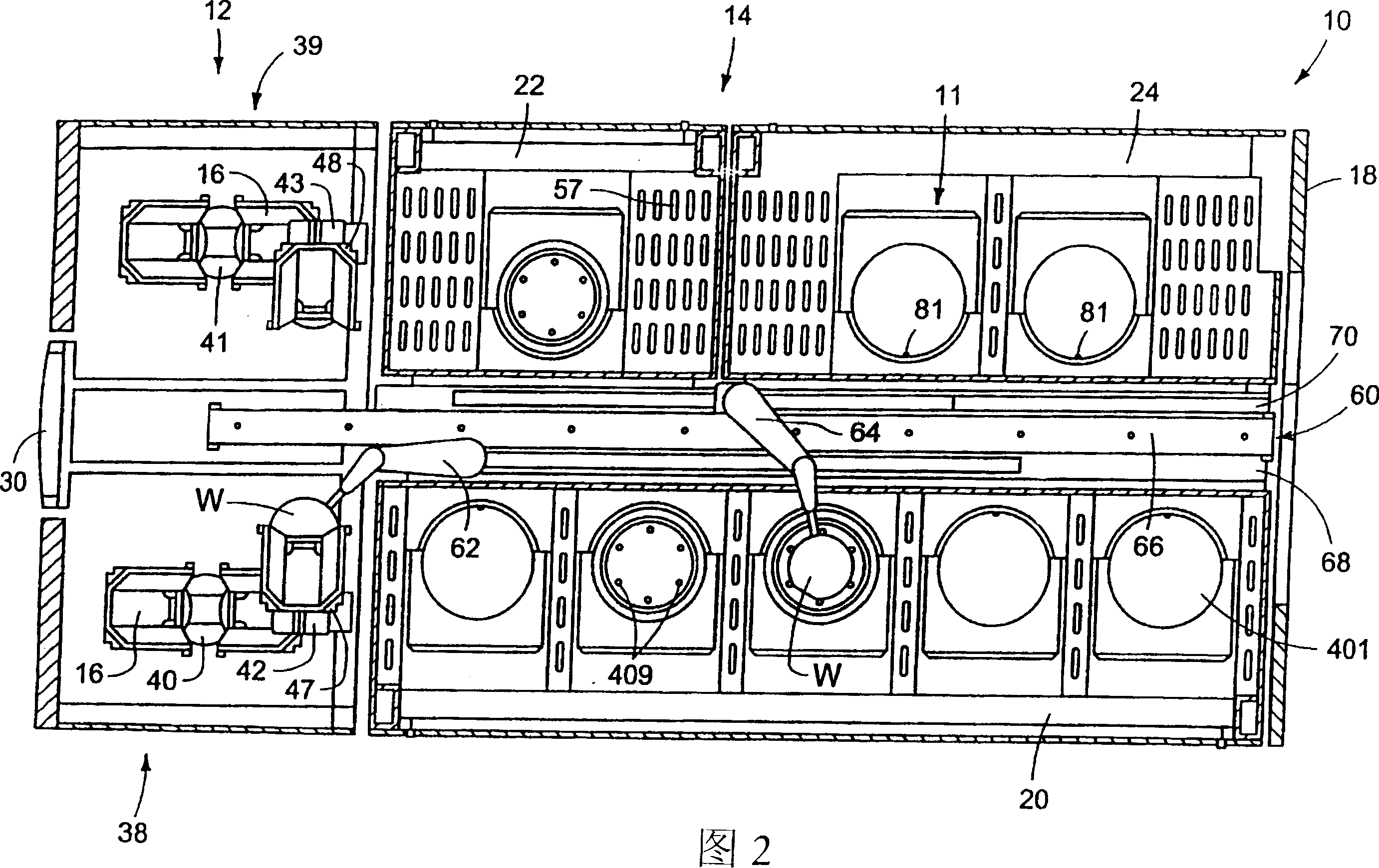

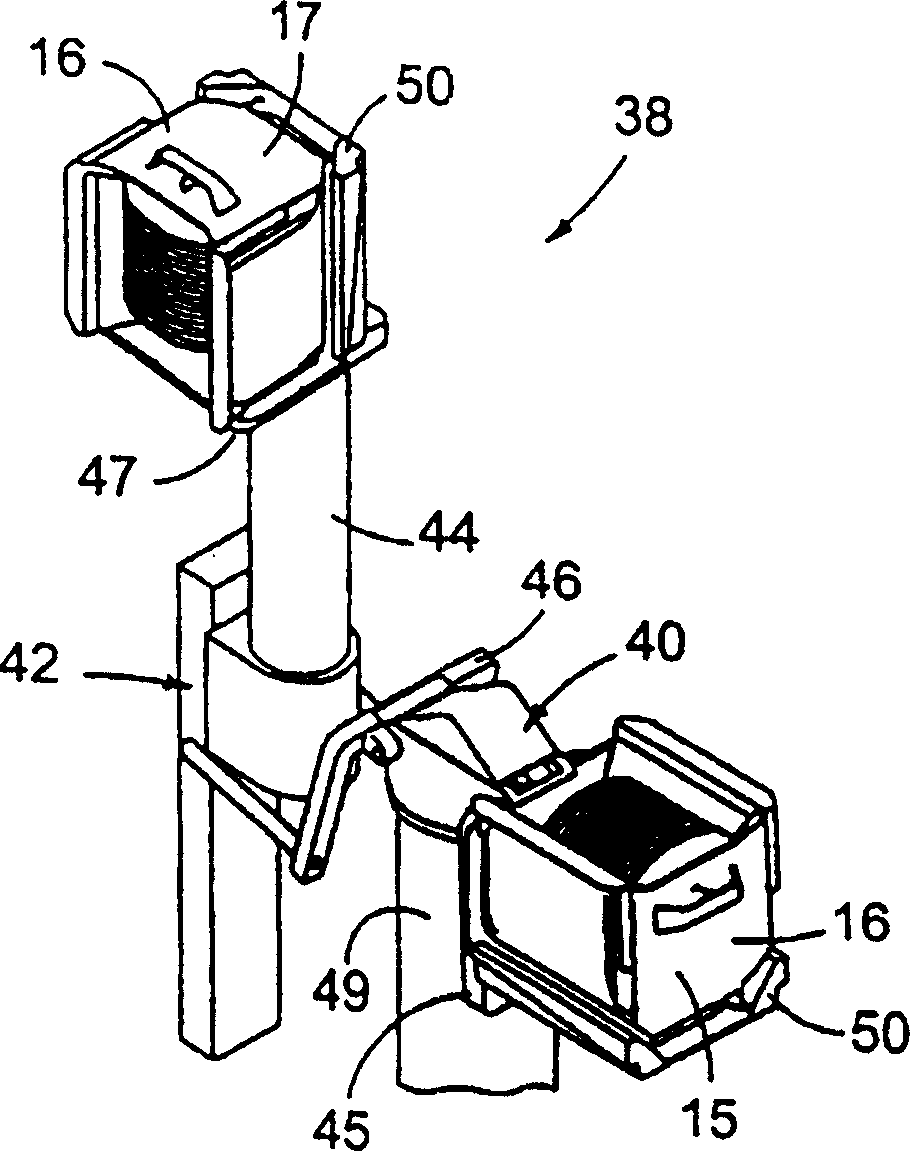

[0024] Referring to FIG. 1, a presently preferred embodiment of a semiconductor wafer processing tool 10 is shown. The processing tool 10 may include an interface portion 12 and a processing portion 14 . A semiconductor wafer cassette 16 containing a plurality of semiconductor wafers, generally designated W, may be loaded into or unloaded from the processing tool 10 through the interface portion 12 . In particular, loading or unloading of wafer cassette 16 is preferably done through at least one port, such as first port 32, in the front exterior surface of the wall facing process tool 10. An additional second port 33 may be provided in the interface portion 12 of the processing tool 10 to improve access, port 32 may be used as an input port and port 33 may be used as an output port.

[0025] The access ports 32, 33 may be covered with respective powered doors 35, 36, thereby isolating the interior of the process tool 10 from the clean room. Each door 35, 36 may comprise two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com