Automatic bag making machine

An automatic bag making machine technology, applied in bag making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of low production efficiency, achieve the effects of improving production efficiency, reducing waste, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The embodiment of the present application discloses an automatic bag making machine.

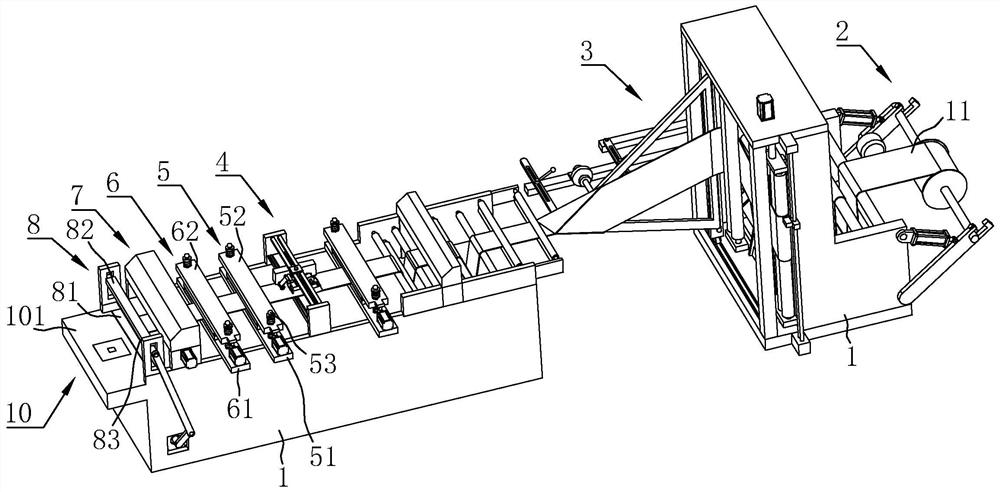

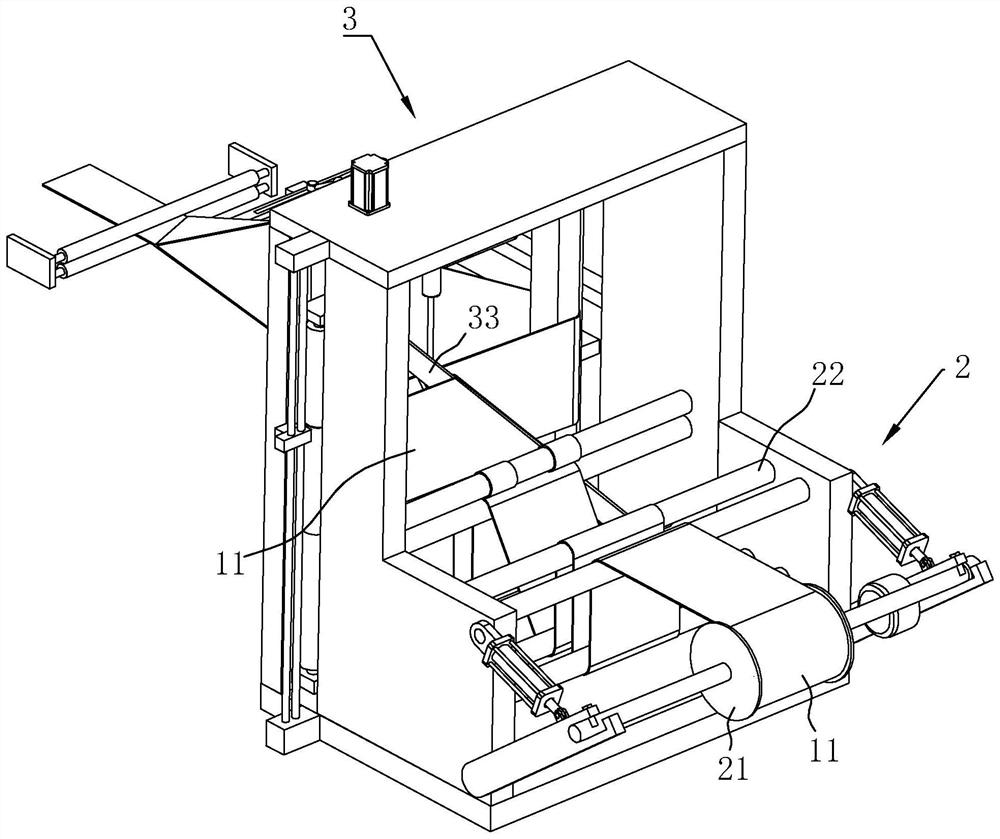

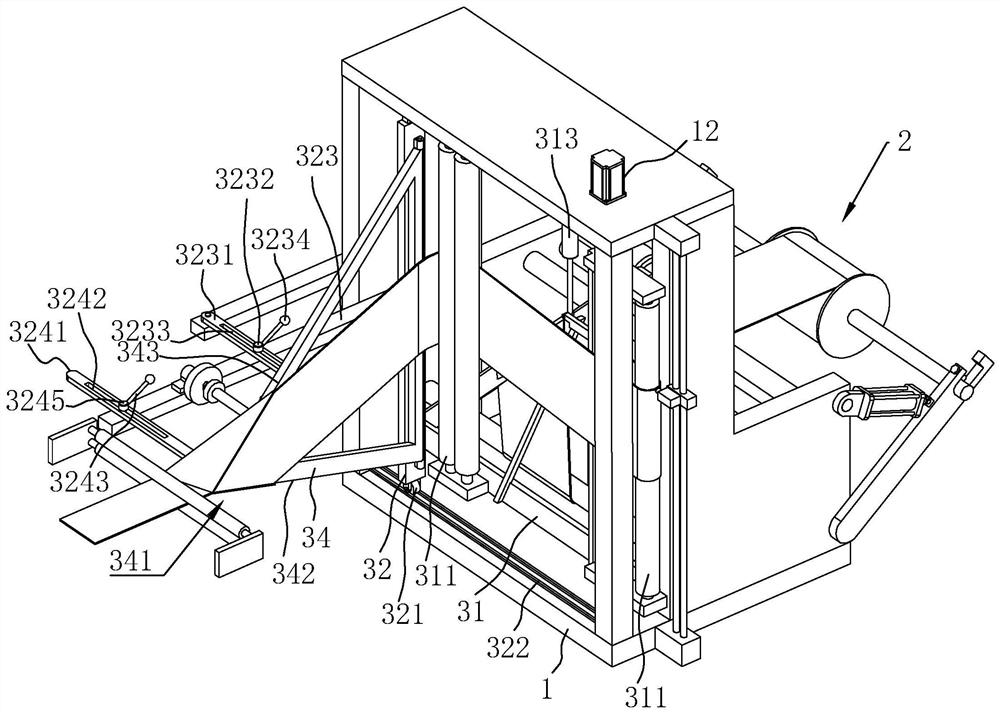

[0054] refer to figure 1 , an automatic bag making machine includes a frame 1 and a feeding mechanism 2, a folding mechanism 3, a bronzing mechanism 4, a heat-sealing mechanism 5, a cooling mechanism 6, a driving mechanism 7, and a material cutting mechanism arranged in sequence along the length direction of the frame 1 8. The receiving mechanism 10; the raw material belt 11 is a plastic film belt, and the raw material belt 11 is continuously transported forward under the action of the driving mechanism 7 to complete the processing of each process. Complete the half-folding of the width direction of the raw material belt 11, and then realize the stamping logo pattern on the surface of the raw material belt 11 through the bronzing mechanism 4, and then heat seal the raw material through the heat-sealing mechanism 5 to form an interval storage chamber after the bronzing is completed. T...

Embodiment 2

[0074] The embodiment of the present application discloses an automatic bag making machine.

[0075] refer to Figure 9 , the difference from Embodiment 1 is that there are three heat-sealing mechanisms 5 arranged at intervals along the length direction of the frame 1, and multiple heat-sealing mechanisms 5 can be selectively selected according to the needs of different products, and the heat-sealing mechanisms 5 and the cooling mechanism 6 are slidingly connected with the frame 1 along the length direction of the frame 1. In specific use, the distance from the cooling mechanism 6 to the material cutting mechanism 8, and the distance from the heat sealing mechanism 5 to the material cutting mechanism 8 are all plastic bag widths. That is, by adjusting the positions of the heat-sealing mechanism 5 and the cooling mechanism 6 before use, the cooling mechanism 6 can be accurately cooled to the heat-sealing strip formed by heat-sealing, and the subsequent cutting mechanism 8 can a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap