Integrated device with transmission shaft having rolling cleaning, coding and discharging functions

A drive shaft, clean technology, used in typewriters, transportation and packaging, printing and other directions, can solve the problems of large manual adjustment errors, cumbersome operations, high labor intensity, etc., to achieve the effect of pinpointing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

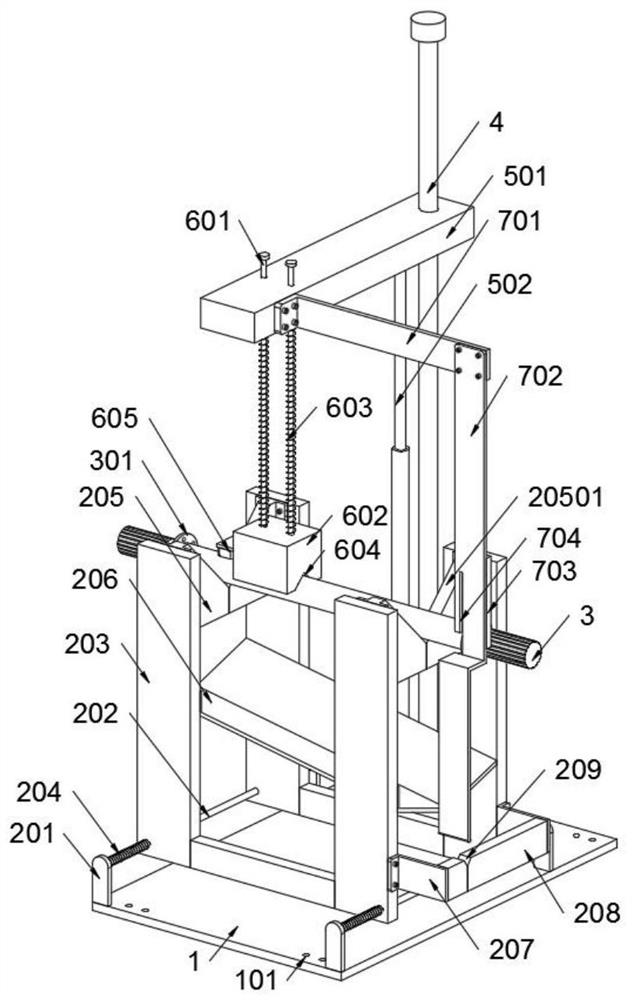

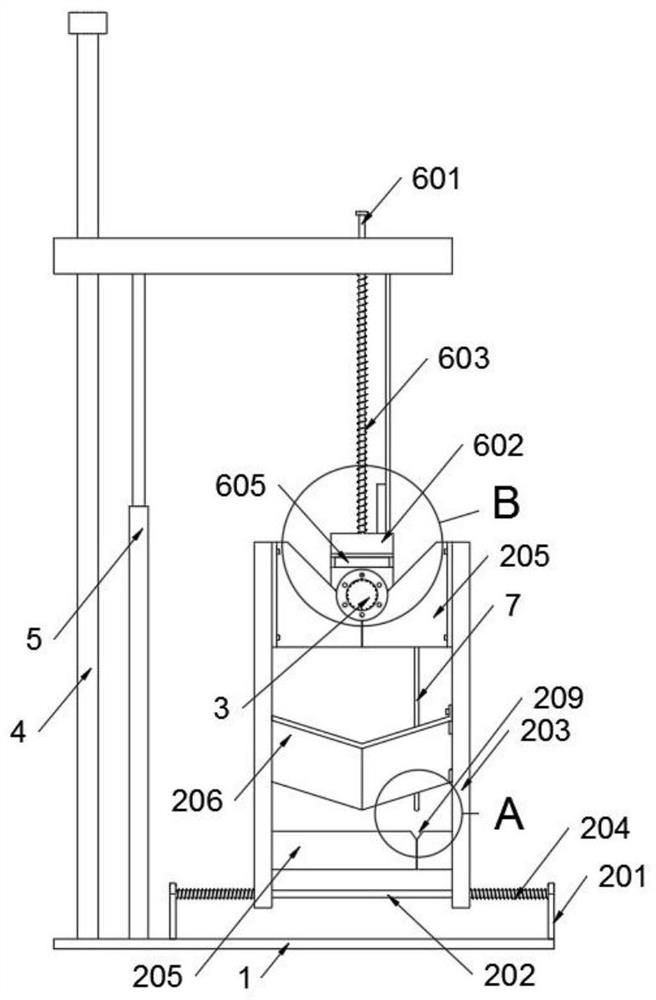

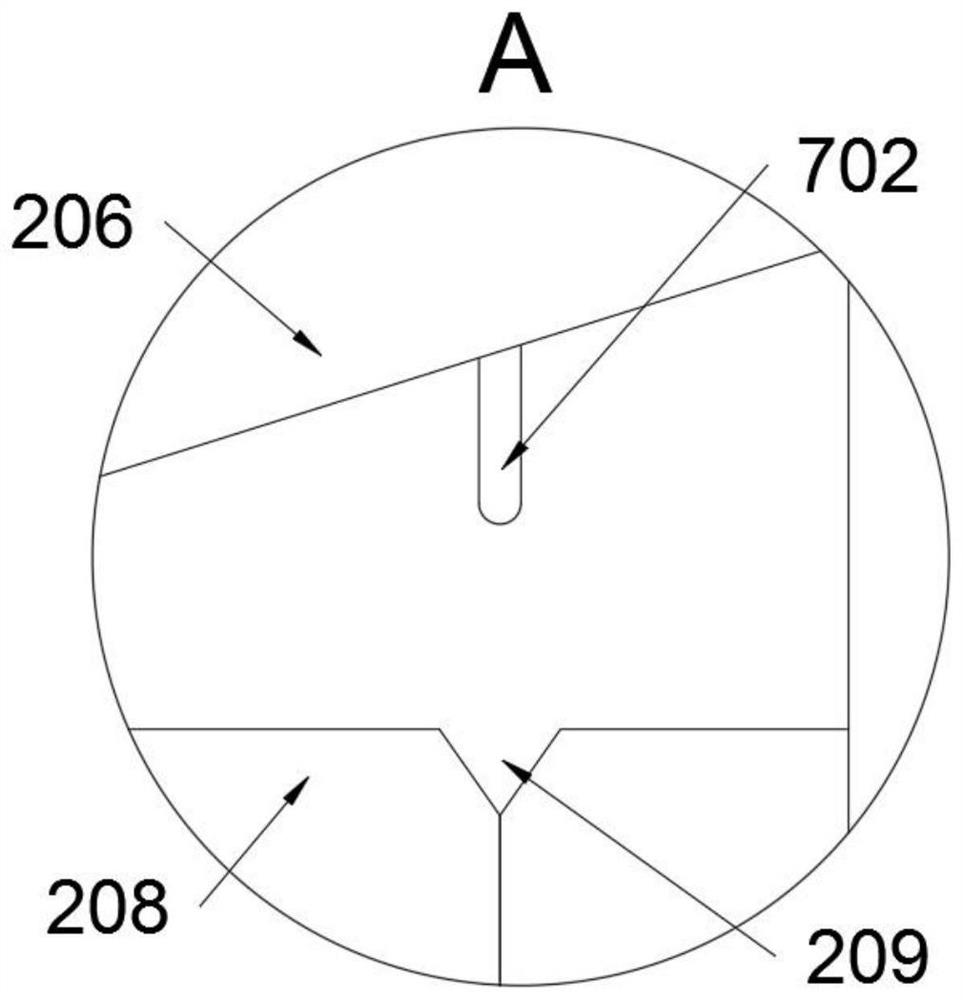

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034] The present invention provides an integrated device for transmission shafts with rolling, cleaning, coding and unloading, including a base 1; a placement structure 2 is welded on the base 1, and a transmission shaft 3 is placed on the placement structure 2, and a sliding bar B4 is welded on the base 1 ; The sliding bar B4 is slidingly connected with an adjustment structure 5, and the adjustment structure 5 is equipped with a coding structure 6, and the adjustment structure 5 is also equipped with a toggle structure 7; figure 1 The toggling structure 7 includes a connecting plate 701, a toggling arm 702 and a friction block 703, the connecting plate 701 is fixedly connected to the sliding arm 501 by bolts, and a toggling arm 702 is fixedly connected to the connecting plate 701 by bolts; The head end of the arm 702 is an arc-shaped structure, and the head end of the toggle arm 702 is aligned with the V-shaped stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com