Sewing machine and sewing machine control method

A sewing machine and sewing table technology, applied in the field of sewing machines, can solve the problems of scrapping, loss of fabrics, and cutting off the front end of the triangle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

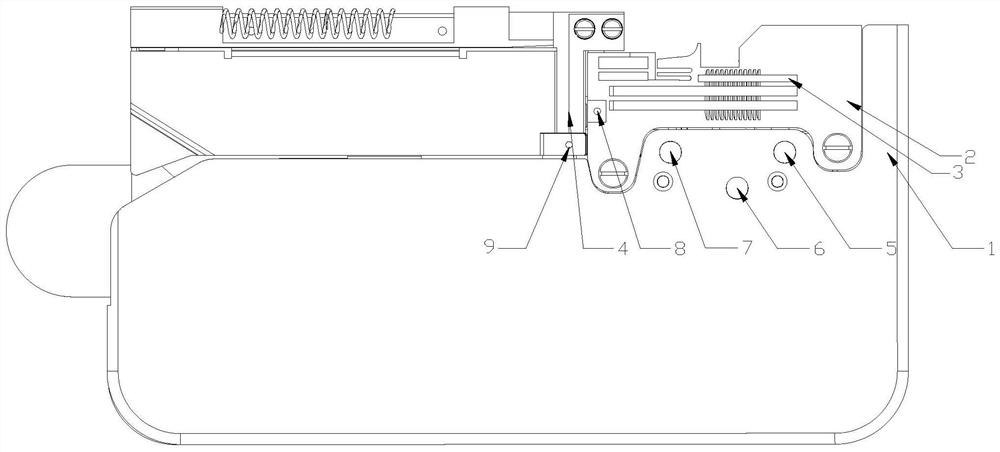

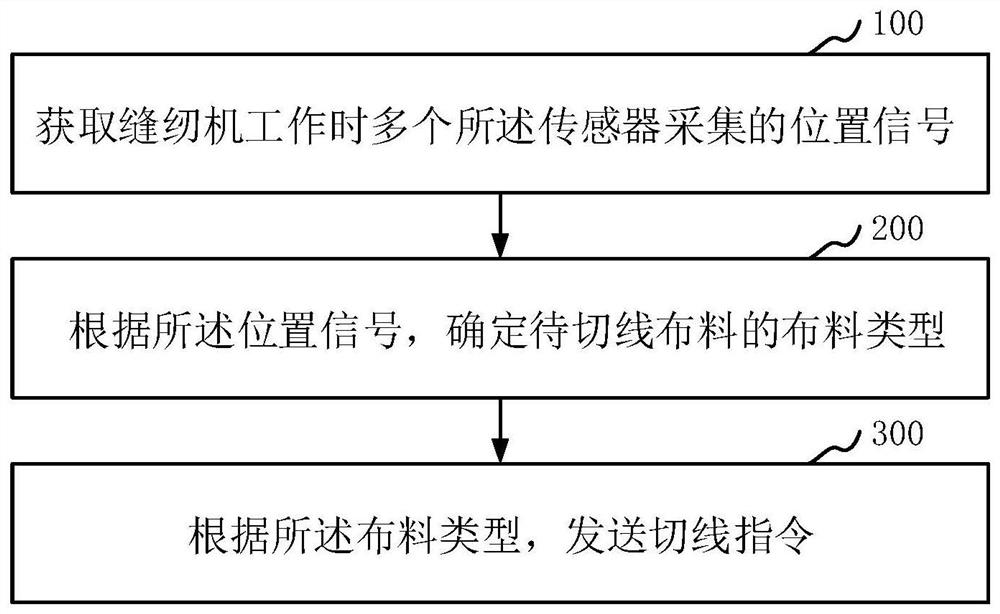

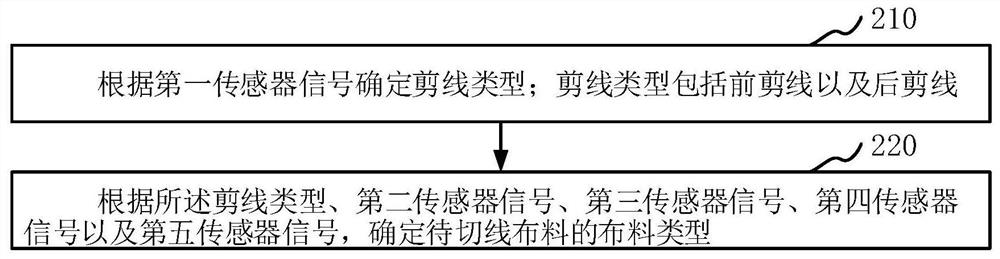

[0059] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

[0060] In the prior art, when the sewing machine sews, a front braid will be formed at the front end of the cloth to be sewn, and a rear braid will be formed at the rear end of the cloth that has been sewn. This requires trimming of the front braids at the start of the sewing machine and trimming of the rear braids at the end of sewing.

[0061] Generally, the end of the cloth to be trimmed is in a flush shape, so when trimming, the time of trimming is judged by a sensor arranged on the sewing table along the advancing direction of the cloth. In the case of front thread t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap