Cutting machine for fabric processing

A cutting machine and fabric technology, applied in the field of fabric processing, can solve the problems of cutting mechanism knife jamming and affecting cutting efficiency, and achieve the effect of changing the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

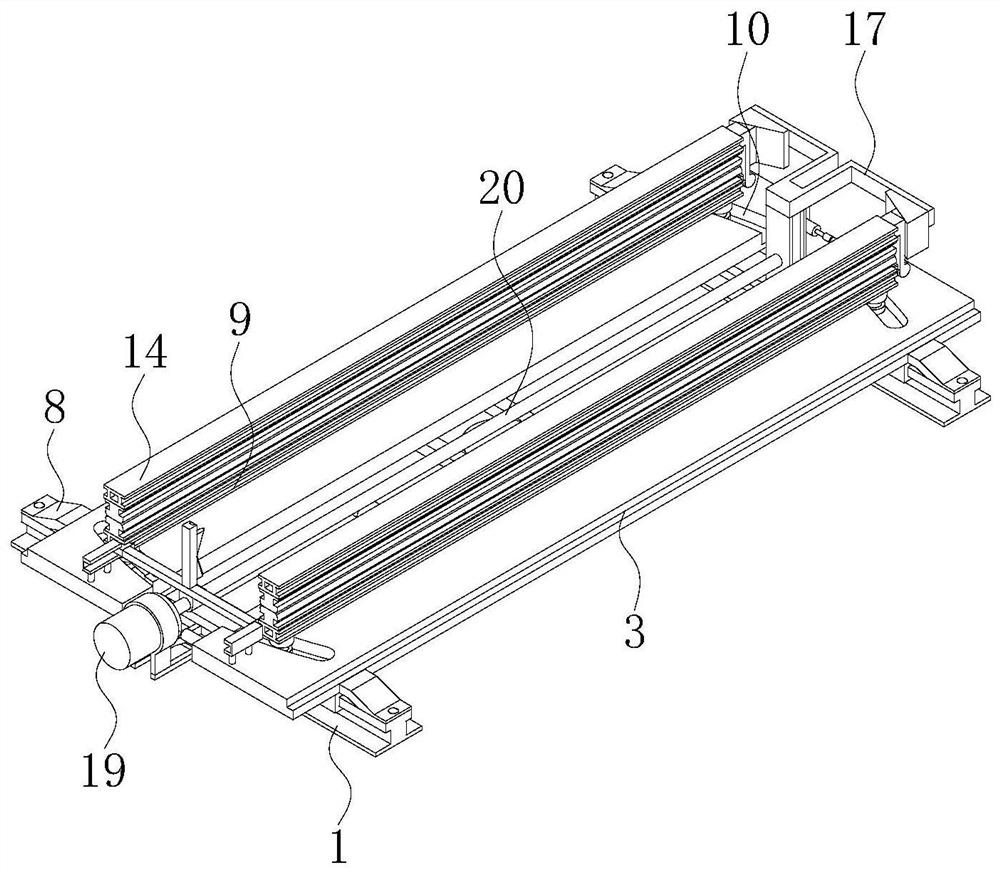

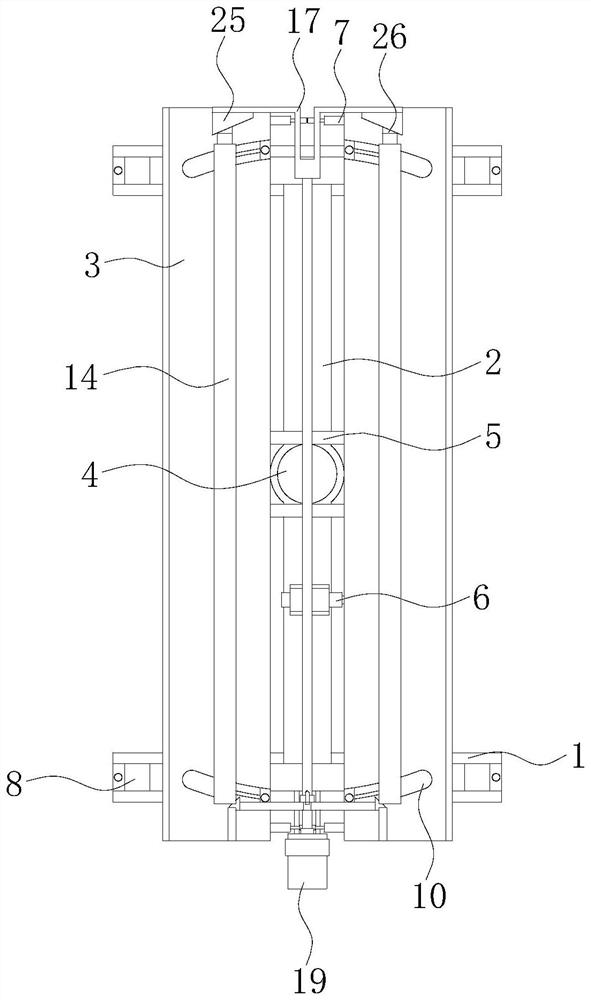

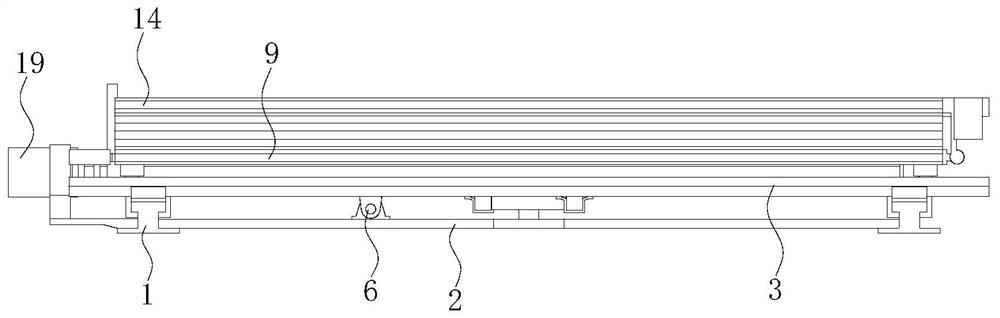

[0025] like Figure 1-7 As shown in the figure, a cutting machine for fabric processing includes two installation rods 1. The installation rods 1 can be installed on a machine for conveying fabrics. Fixed connection, two horizontally distributed support plates 3 are arranged above the two installation rods 1, the left and right ends of the support plate 3 are respectively slidably connected with the upper ends of the two installation rods 1, and the horizontal plate 2 is located between the two support plates 3. During the time, a positioning gear 4 is installed on the upper surface of the horizontal plate 2, and a rack 5 is fixedly installed on the bottom surface of the two supporting plates 3. The two racks 5 are respectively located on the left and right sides of the positioning gear 4 and mesh with it. 4. The two pallets 3 can be made close to each other or away from each other, the displacement of the two pallets 3 is the same, the upper surface of the horizontal plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com