Adjustable instruction cable terminal

A cable terminal, adjustable technology, applied in the direction of flexible shaft, linear motion shaft, shaft, etc., can solve the problems of complex adjustment, difficult to ensure the correct torque of the reverse screw, time-consuming and labor-intensive, and achieve simple operation and safe adjustment. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

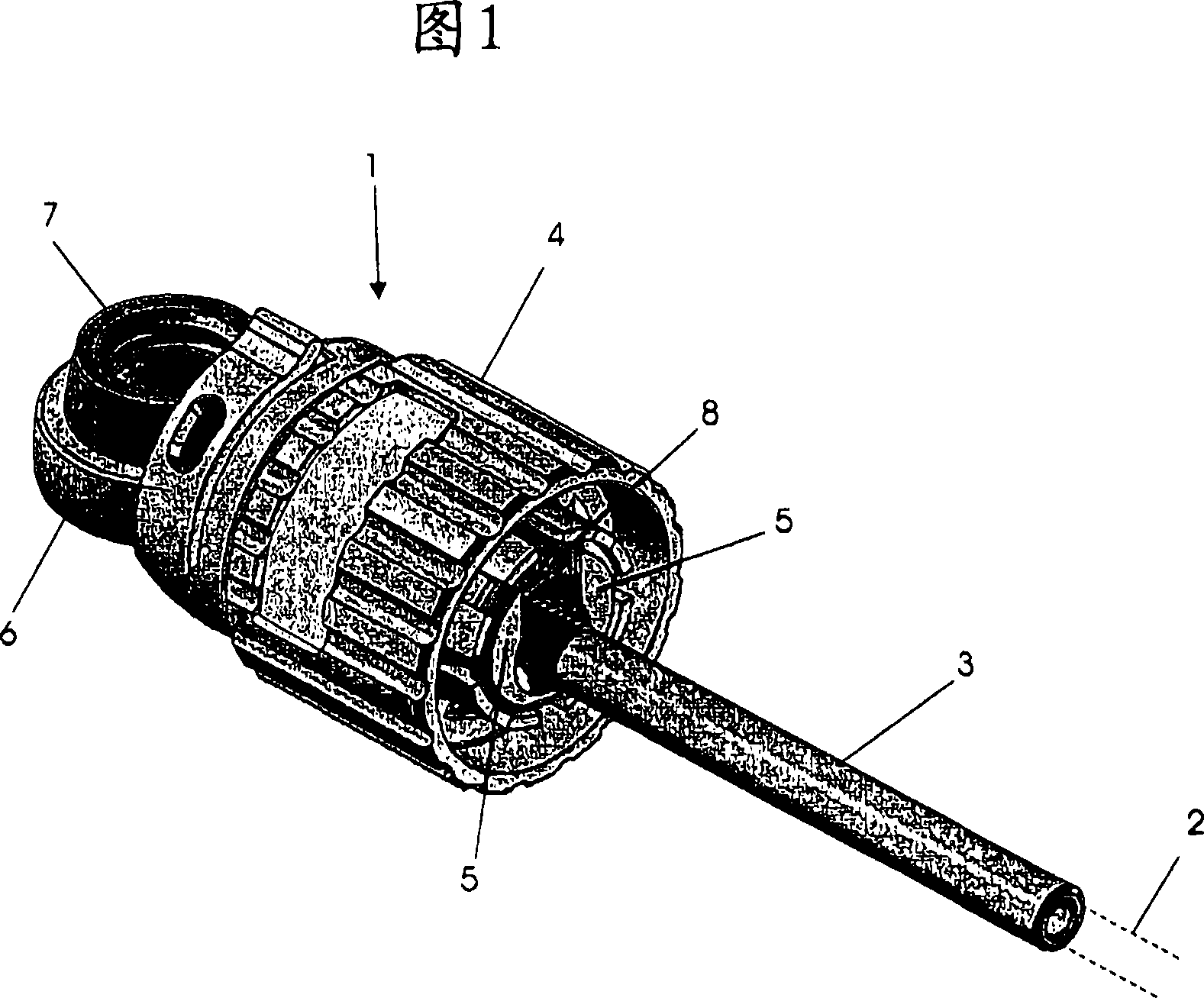

[0037] See the individual drawings for more details. Figure 1 shows a fixture 1 which, in operation, transmits movement and command forces from a transmission mechanism (not shown) to a flexible inner cable 2 fixed on a shaft 3 and through it to a cable 2 command receiving device on the other end.

[0038] The fixture 1 allows free movement of the shaft 3 associated with the flexible cable 2 once the command system is assembled, or when readjustment of the dimensions of the cable is required. After the length of the cable 2 is adjusted again, the shaft 3 combined with the cable 2 should be fixed on the fixing device 1 again.

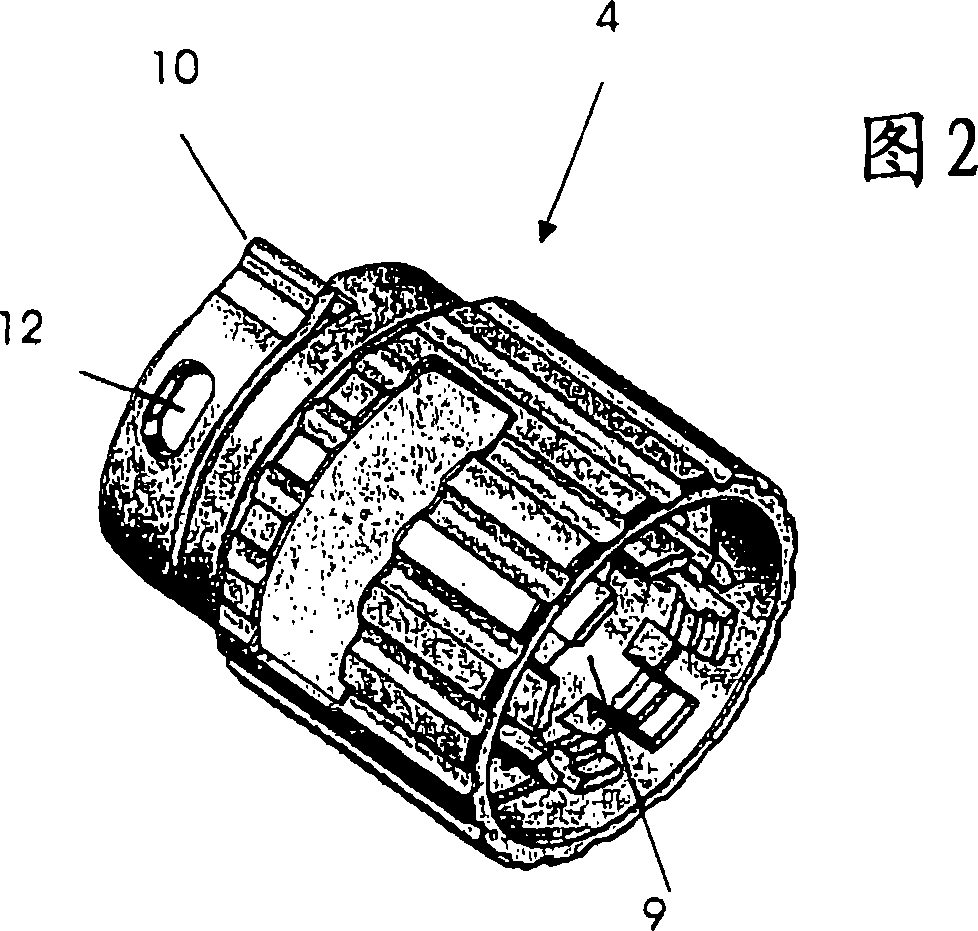

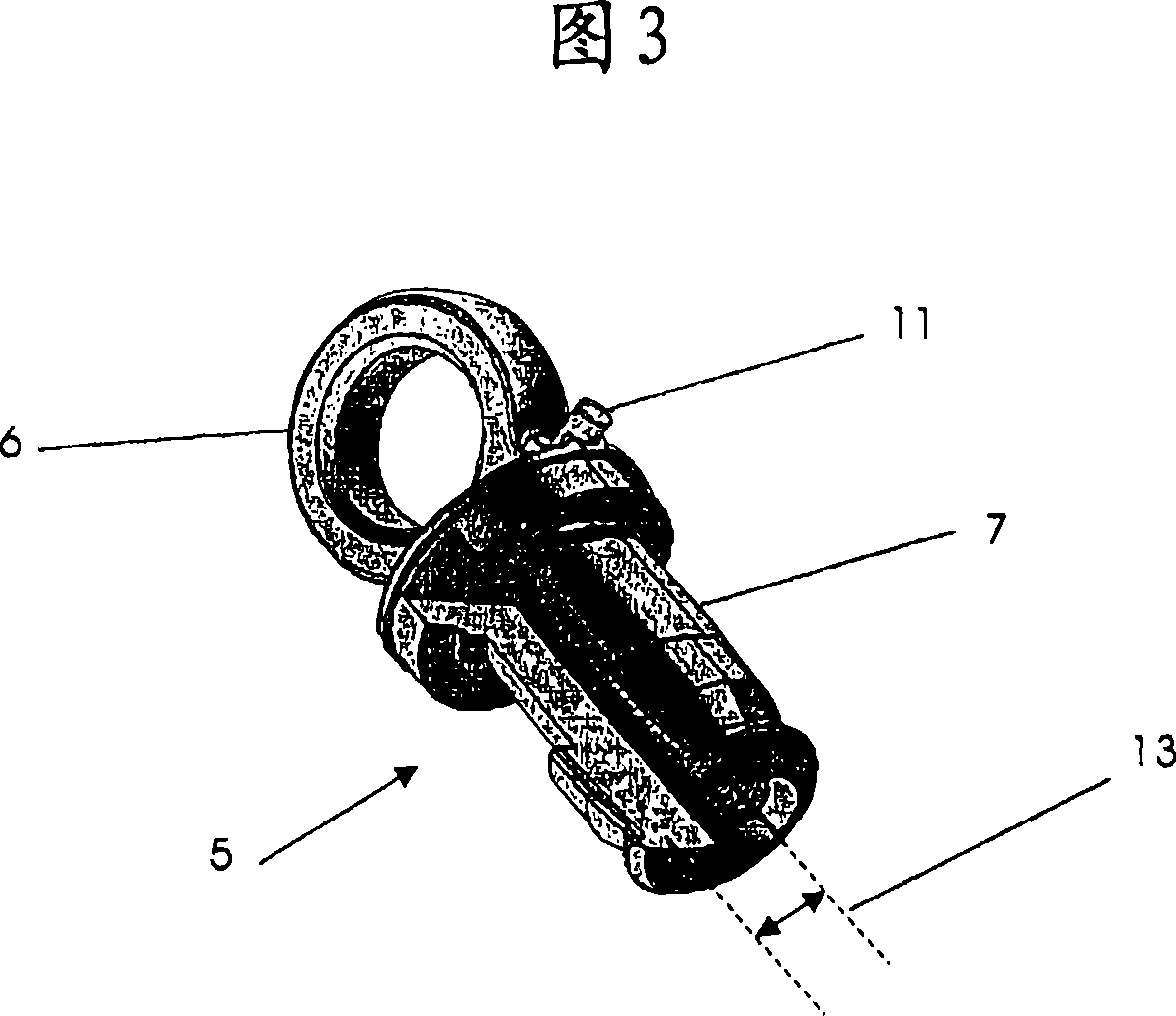

[0039] Also in Fig. 1, the parts in the fixing device 1 can be: the shaft 3, the sheath 4, the inner terminal 5 with its annular head 6 combined with it, and the spherical bush 7, which is placed on the said Inside the ring head 6. The central hole of the spherical lining 7 is hinged on an instruction transmission mechanism not shown in the figure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com