Tensioning construction method on post-tensioning method unbonded prestressed tendon beam

A technology of prestressed beams and construction methods, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of unsuitable control of the quality of anchor sealing, difficult operation of anchor sealing, and cumbersome operation process, so as to save labor and Materials, quick tensioning construction, and the effect of completing tensioning construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0025] A post-tensioning construction method for unbonded prestressed tendon beams according to the present invention, by arranging the tension end of the prestressed steel strands on the prestressed beams, the tensioning construction and anchor sealing can be completed on the beams Construction, and then achieve the technical effect of safe and fast completion of tensioning construction.

[0026] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

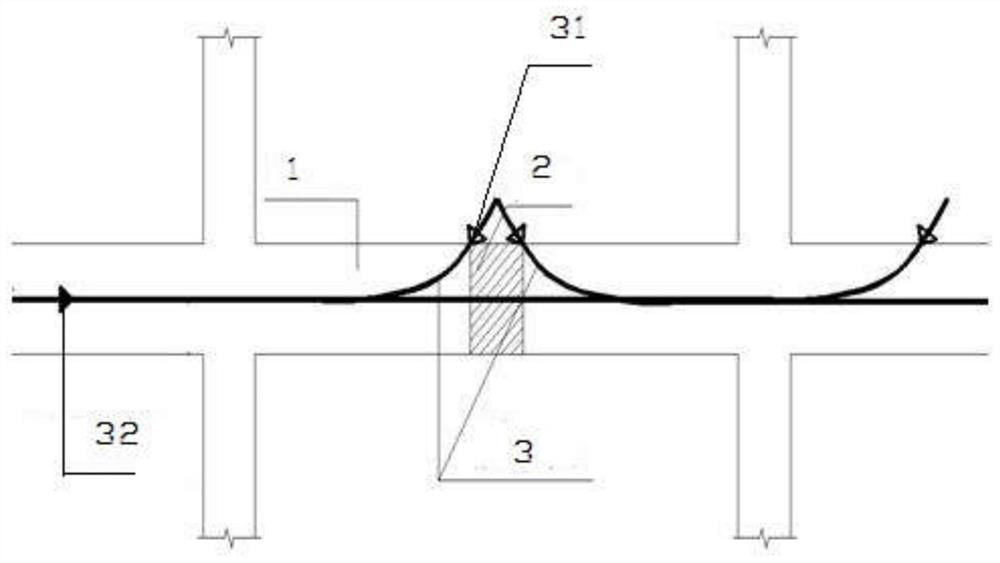

[0027] figure 1 An overall description of the scenario of the post-tensioned unbonded prestressed tendon beam over-tensioning construction method is given. Specifically, figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com