Comprehensive testing device for RV speed reducer

A comprehensive test, reducer technology, applied in the direction of measuring device, machine/structural component test, mechanical component test, etc., can solve the problem of departure from the real working conditions, the position of the load device and the size of the load cannot be dynamically adjusted, and the test results are inconsistent. precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] First, let’s introduce the application scenario of this embodiment. The test device 100 provided in the embodiment of this application can be applied to the accuracy characteristic test of a high-precision reducer, such as an RV reducer, and can also be applied to the accuracy characteristic test of an ordinary precision reducer. , a wide range of applications.

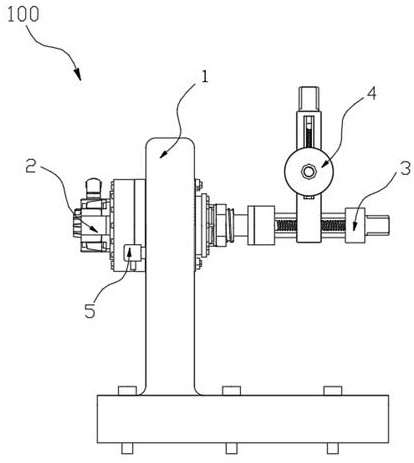

[0043] see Figure 1 to Figure 10 , the test device 100 according to this embodiment includes a rotary mechanism 2, an X moving mechanism 3, a Z moving mechanism 4, an information collection card 6, a rack 1 for installing the rotary mechanism 2, a computer terminal 7, and a display terminal 8.

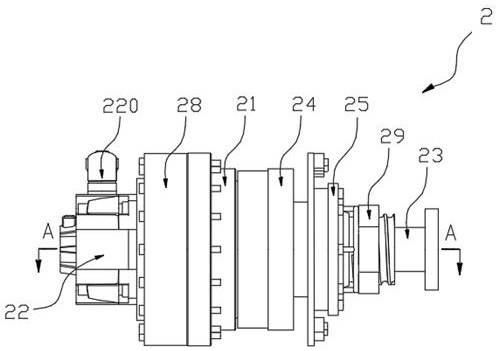

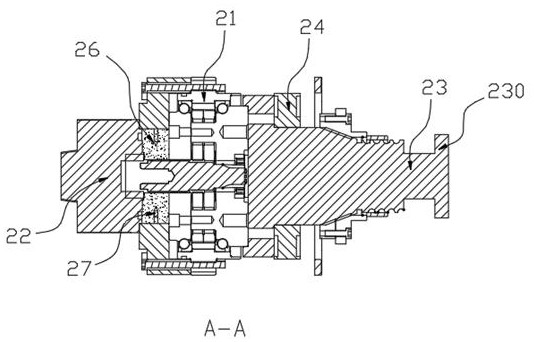

[0044] see Figure 1 to Figure 3 , the slewing mechanism 2 includes a reducer 21, the input end of the reducer 21 is connected with the servo motor 22 through the end cover 28, the servo motor 22 is equipped with an encoder, the output end of the reducer 21 is connected with the output shaft 23, and the output shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com