Fuel cell heat dissipation module and automobile

A fuel cell and heat dissipation module technology, which is applied in the direction of fuel cell heat exchange, fuel cell, fuel cell additives, etc., to achieve the effects of increasing heat dissipation, improving overall heat dissipation, and increasing air intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present disclosure will be described in more detail below. Although preferred embodiments of the present disclosure are described below, it should be understood that the present disclosure can be implemented in various forms and should not be limited by the embodiments set forth herein.

[0028] A fuel cell is a power generation device that converts the chemical energy of fuel (hydrogen and air) into electrical energy. It is considered to be an important direction for the sustainable development of the future automotive industry because of its advantages such as high efficiency, zero emissions, and low noise.

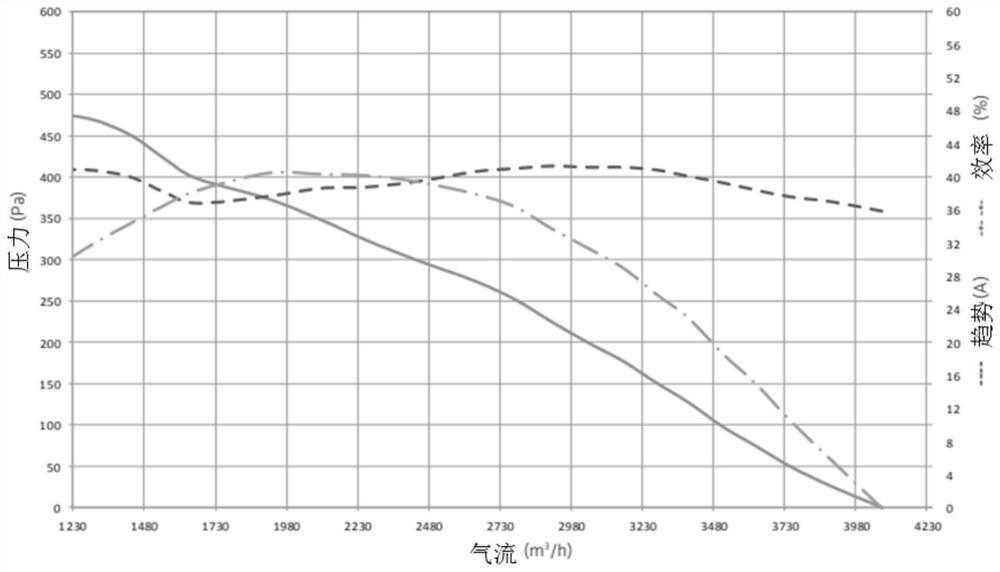

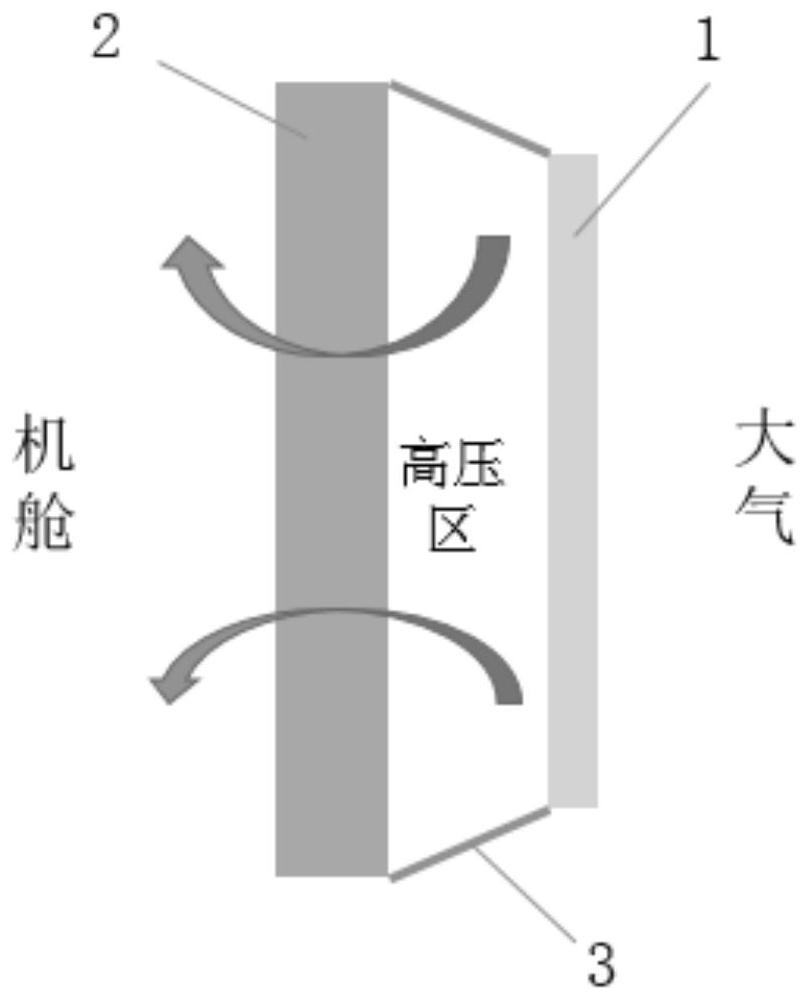

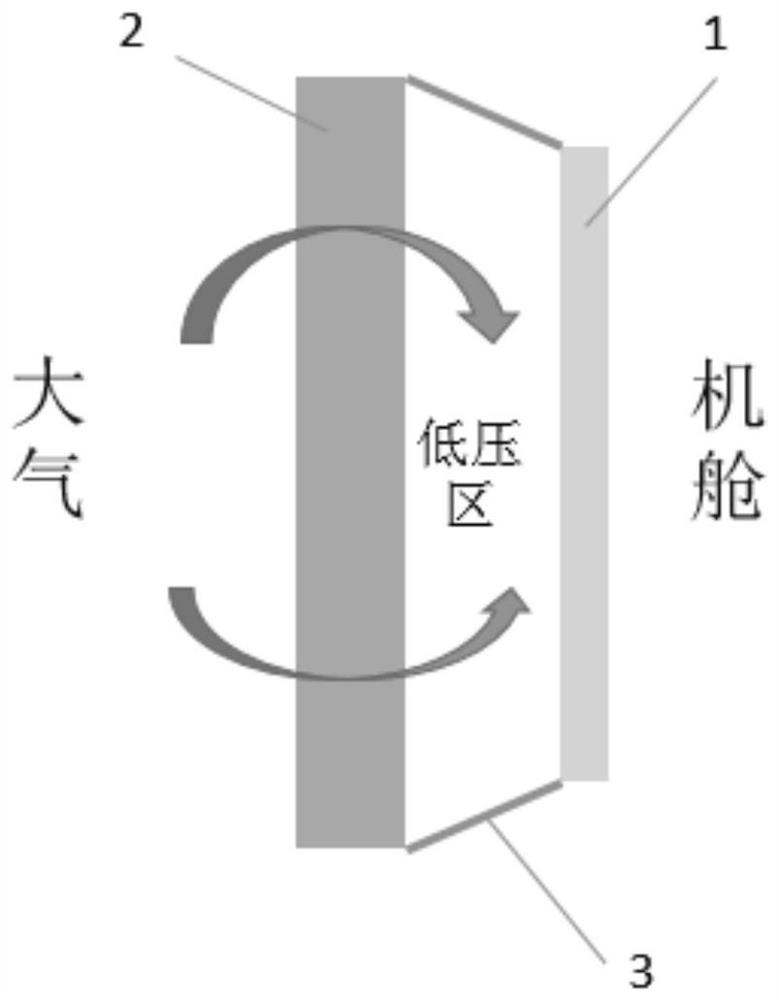

[0029] In the design and development of the fuel cell heat dissipation system, the heat exchange area and air intake volume will be calculated according to the heat dissipation requirements of the vehicle. The heat exchange area is determined by the radiator 2, and the air intake volume is determined by the cooling fan 1, which is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com