Planting auxiliary mechanism with built-in grafting structure for crabapple stem grafting

An auxiliary mechanism, technology of crabapple branch, applied in the field of planting auxiliary mechanism with built-in grafting structure for crabapple branch grafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

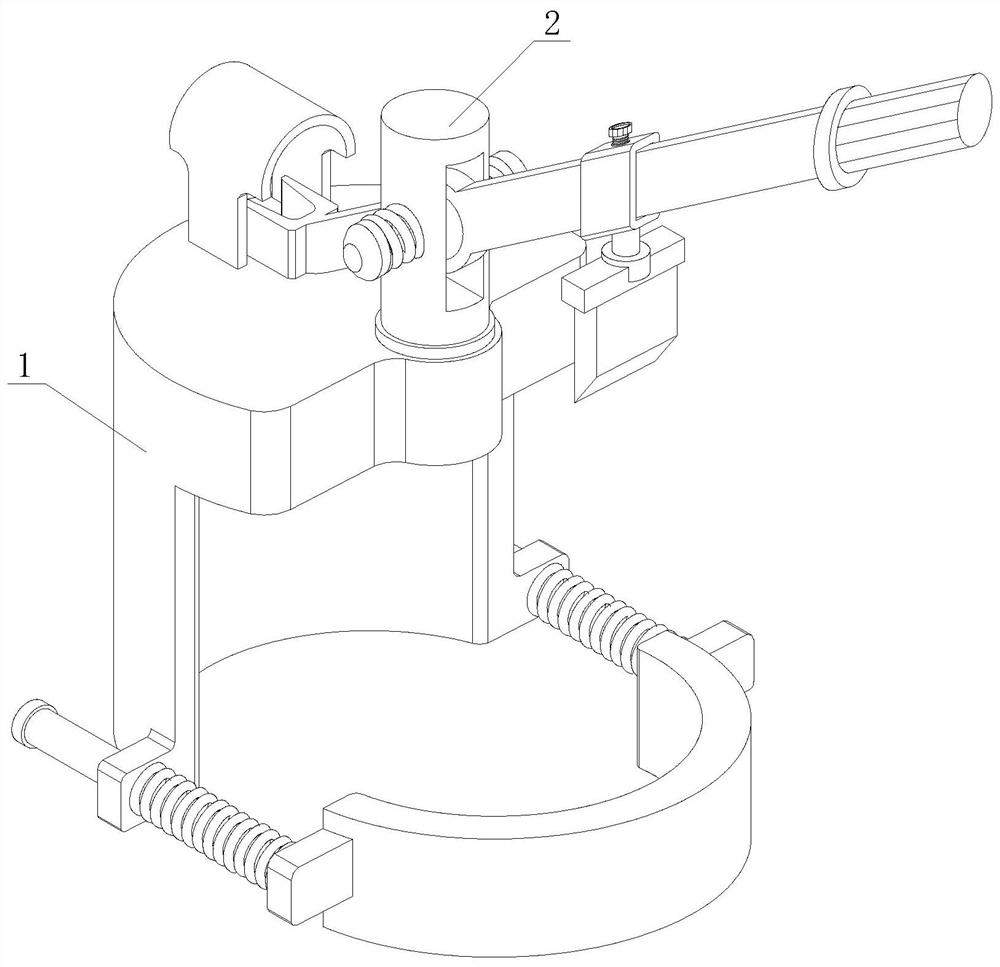

[0027] see figure 1 , a planting auxiliary mechanism with a built-in grafting structure for crabapple branch grafting, comprising a clamping and fixing mechanism 1 and a grafting incision mechanism 2, and the grafting and incision mechanism 2 is fixedly installed on the clamping and fixing mechanism 1.

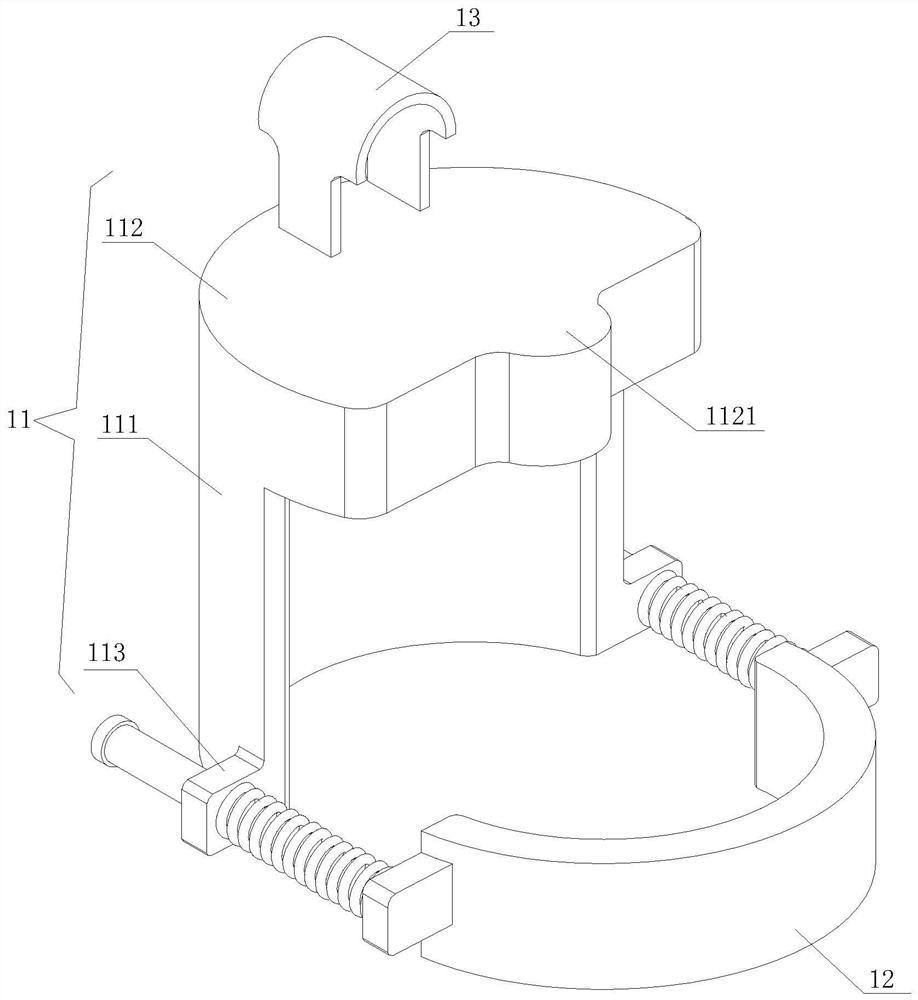

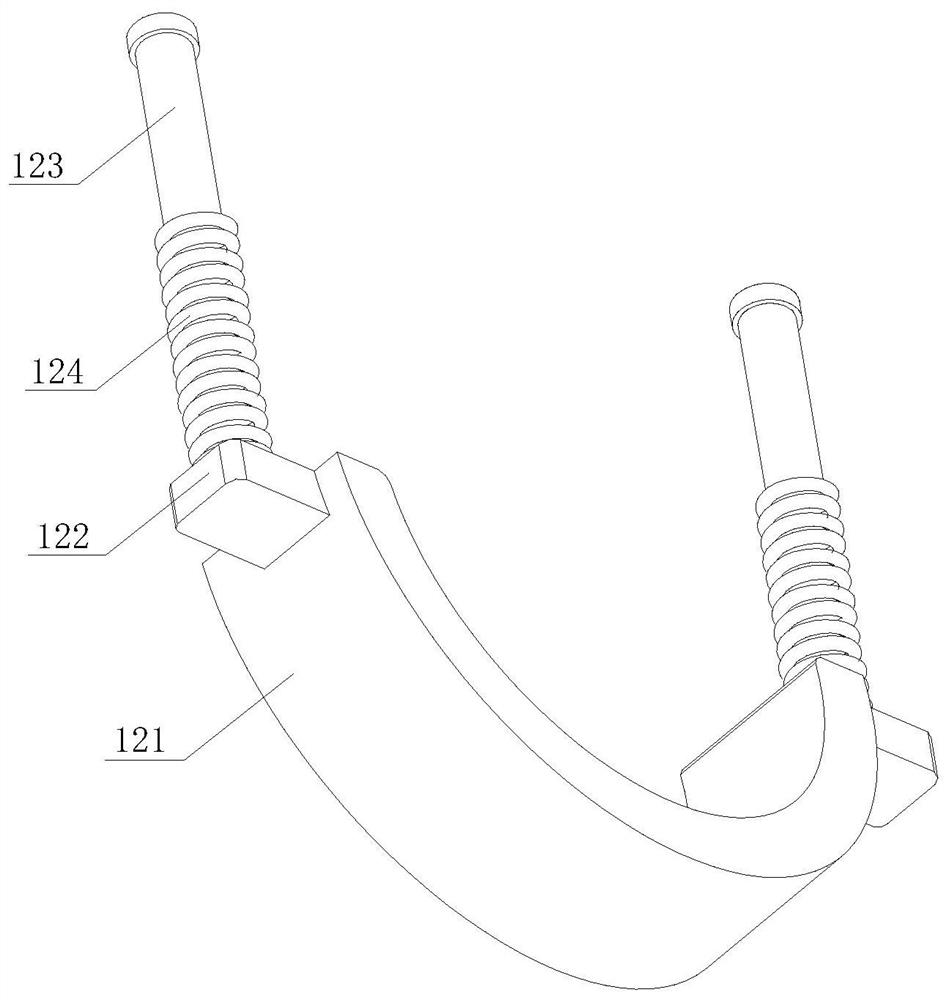

[0028] see Figure 2-3 , the clamping and fixing mechanism 1 is provided with a rootstock fixing component 11, a clamping collar component 12 and a limit stop frame 13, and one end of the rootstock fixation component 11 is movable to install the clamping collar component 12, and the limit stop frame 13 is fixedly welded on the rootstock The upper end of the fixing assembly 11, and the grafting incision mechanism 2 is fixedly installed on the upper end of the rootstock fixing assembly 11.

[0029] The rootstock fixing assembly 11 is provided with an arc-shaped fixing piece 111, a semicircle support plate 112 and a connecting hole block 113, the upper end of the arc-shaped fixi...

Embodiment 2

[0033] see figure 1 , a planting auxiliary mechanism with a built-in grafting structure for crabapple branch grafting, comprising a clamping and fixing mechanism 1 and a grafting incision mechanism 2, and the grafting and incision mechanism 2 is fixedly installed on the clamping and fixing mechanism 1.

[0034] see Figure 2-3 , the clamping and fixing mechanism 1 is provided with a rootstock fixing component 11, a clamping collar component 12 and a limit stop frame 13, and one end of the rootstock fixation component 11 is movable to install the clamping collar component 12, and the limit stop frame 13 is fixedly welded on the rootstock The upper end of the fixing assembly 11, and the grafting incision mechanism 2 is fixedly installed on the upper end of the rootstock fixing assembly 11.

[0035] The rootstock fixing assembly 11 is provided with an arc-shaped fixing piece 111, a semicircle support plate 112 and a connecting hole block 113, the upper end of the arc-shaped fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com