Factory raw material residual material quantity detection feedback system

A technology for detecting feedback and raw materials, applied in mixing plants, ingredient storage, control devices, etc., can solve problems such as inconvenient user management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of this application clearer, the following in conjunction with the attached Figure 1-3 And embodiment, this application is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

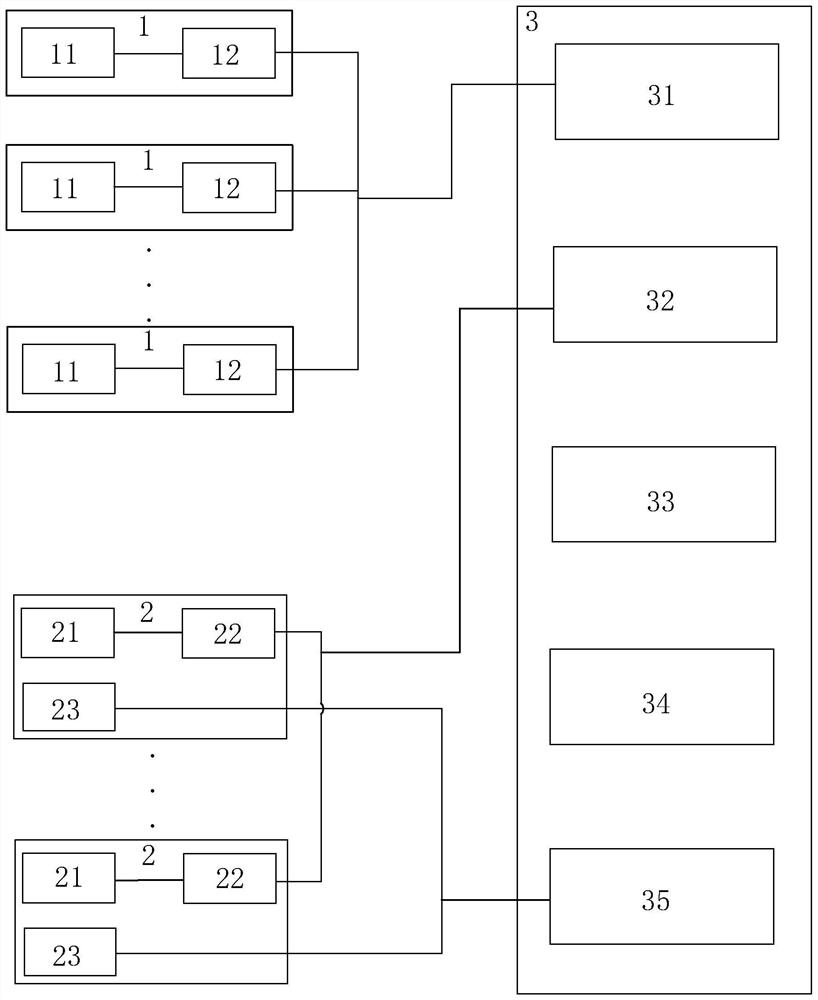

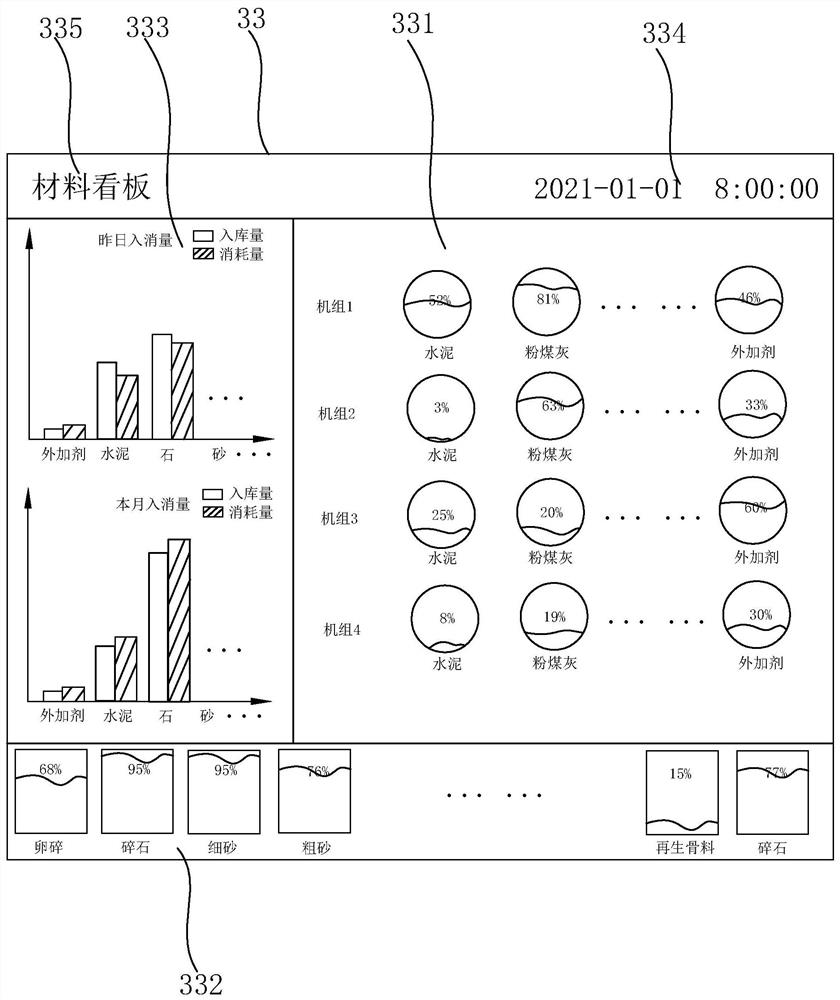

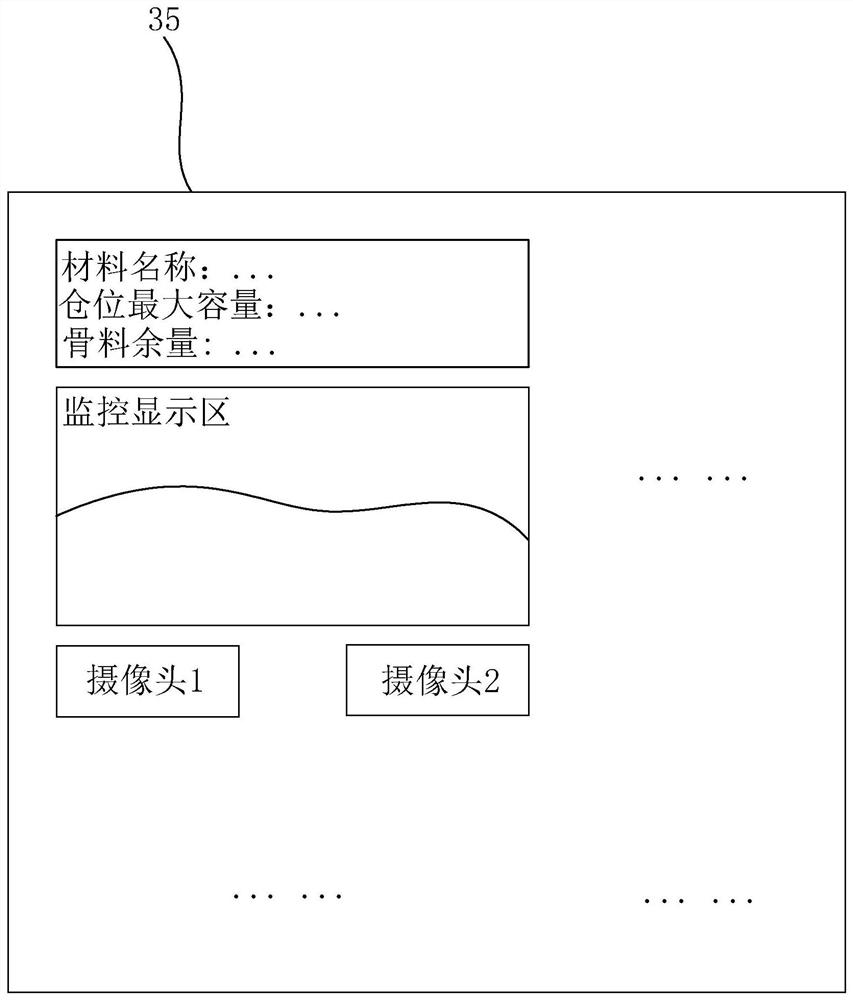

[0035] The embodiment of the present application discloses a detection and feedback system for the remaining amount of raw materials in a factory area. refer to figure 1 A detection and feedback system for the remaining amount of raw materials in a factory area includes a powder tank residual material detection device 1, an aggregate bin residual material detection device 2, and a warehouse management module 3; the warehouse management module 3 includes a powder tank management sub-module 31, an aggregate The bin management sub-module 32 and the material balance display panel 33.

[0036] like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com