Impurity removing equipment for polypropylene

A polypropylene and equipment technology, applied in the field of polypropylene impurity removal equipment, can solve the problems that the solution cannot be effectively stirred, affect the polypropylene impurity removal effect, etc., and achieve the effect of slowing down the resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

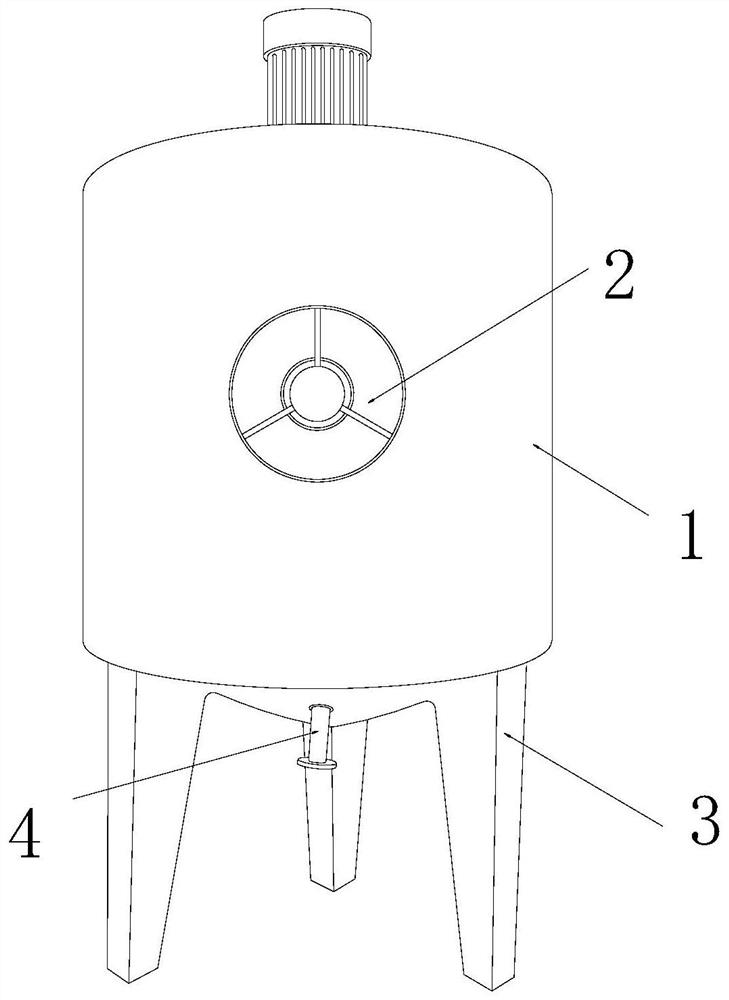

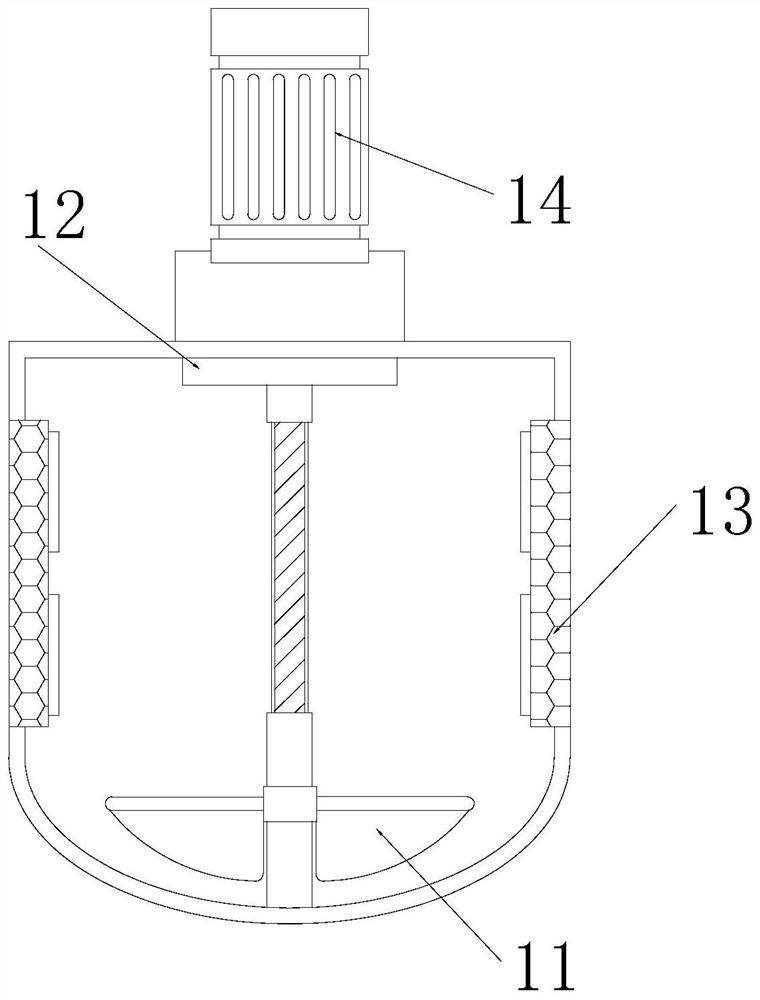

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides an impurity removal equipment for polypropylene, the structure of which includes an impurity removal tank 1, a valve 2, a bracket 3, and a discharge port 4. The outer end surface of the impurity removal tank 1 is movably fitted with a valve 2, and the valve 2 is located directly above the discharge port 4, the bracket 3 is fixed on the lower end surface of the trash discharge tank 1 by welding, and the discharge port 4 is embedded and installed on the lower end surface of the trash discharge tank 1; the trash discharge tank 1 It includes a stirring mechanism 11, a turntable 12, a heater 13, and a motor 14. The stirring mechanism 11 is embedded and mounted on the lower surface of the turntable 12. The heater 13 is symmetrically installed on the left and right ends of the stirring mechanism 11 , and the motor 14 is embedded directly above the stirring mechanism 11 .

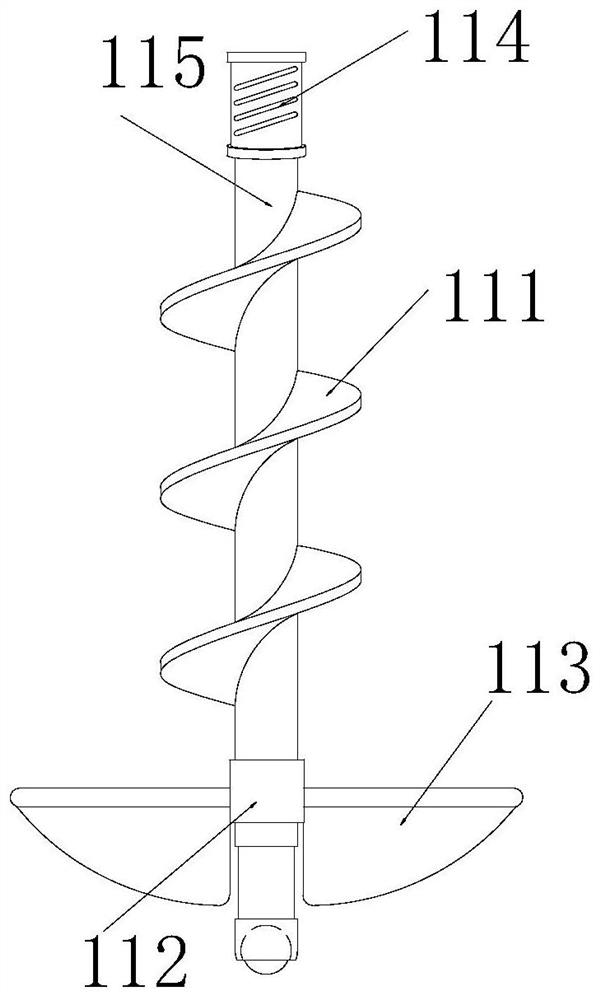

[0027] Wherein, the st...

Embodiment 2

[0033] as attached Figure 6 to attach Figure 7 Shown:

[0034]Wherein, the guide piece 113 includes an arc block 131, a guiding mechanism 132, a limit block 133, a spring 134, and a nesting shaft 135, and the upper end surface on the right side of the arc block 131 is inlaid and engaged with the nesting shaft 135, The guide mechanism 132 is embedded on the inner end surface of the arc block 131, the limiting block 133 is embedded and fixed on the outer end surface of the nested shaft 135, and the spring 134 is fixed on the upper left side of the nested shaft 135 by welding , the nested shaft 135 is inlaid and engaged with the lifting mechanism 112, and the left end surface of the arc block 131 has an arc-shaped outer contour, which can make the stirring mechanism 112 rotate at the same time. solution to guide.

[0035] Wherein, the guide mechanism 132 includes an inclined plane groove 321, a cavity 322, an air bag 323, an arc block 324, and a closing plate 325. On the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com