Blade motor directly driven multi-redundance electromagnetic piloted safe water attack pressure release valve

A technology of electromagnetic pilot valve and vane motor, applied in safety valve, balance valve, valve device, etc., can solve the problem of inability to automatically release pressure, and achieve the effect of facilitating intelligent control, improving work reliability, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

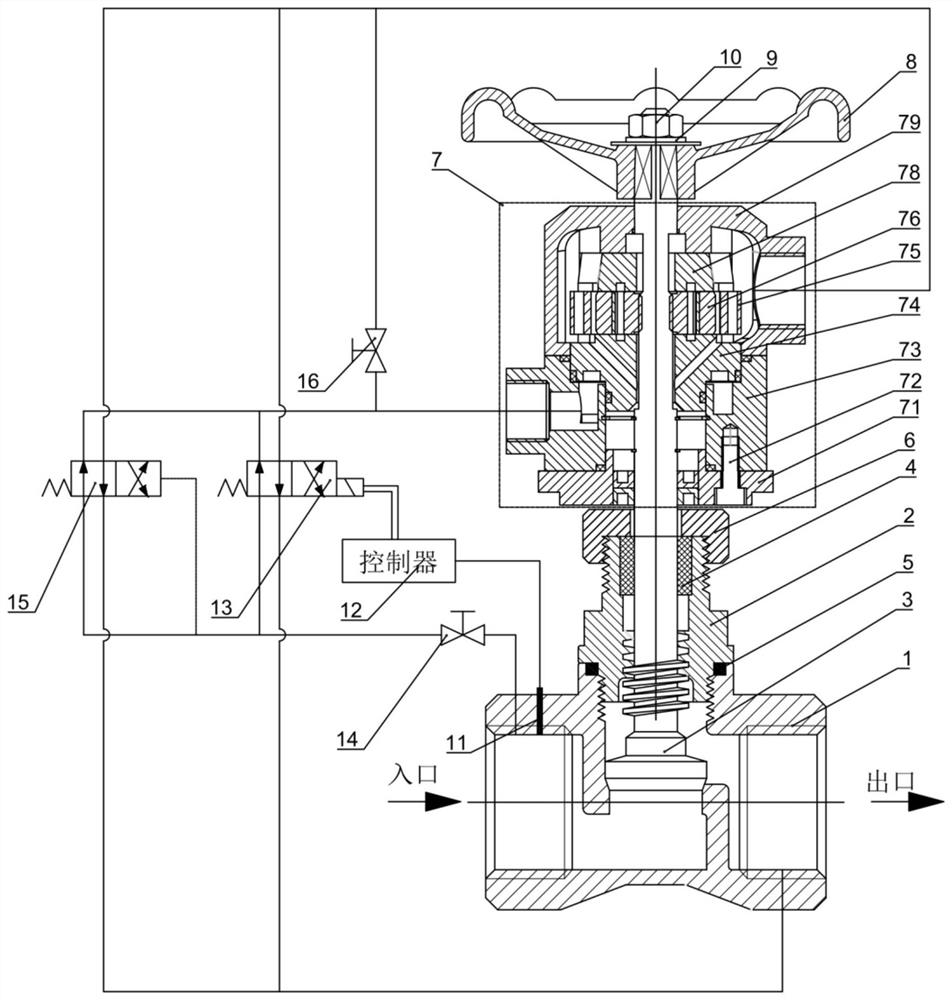

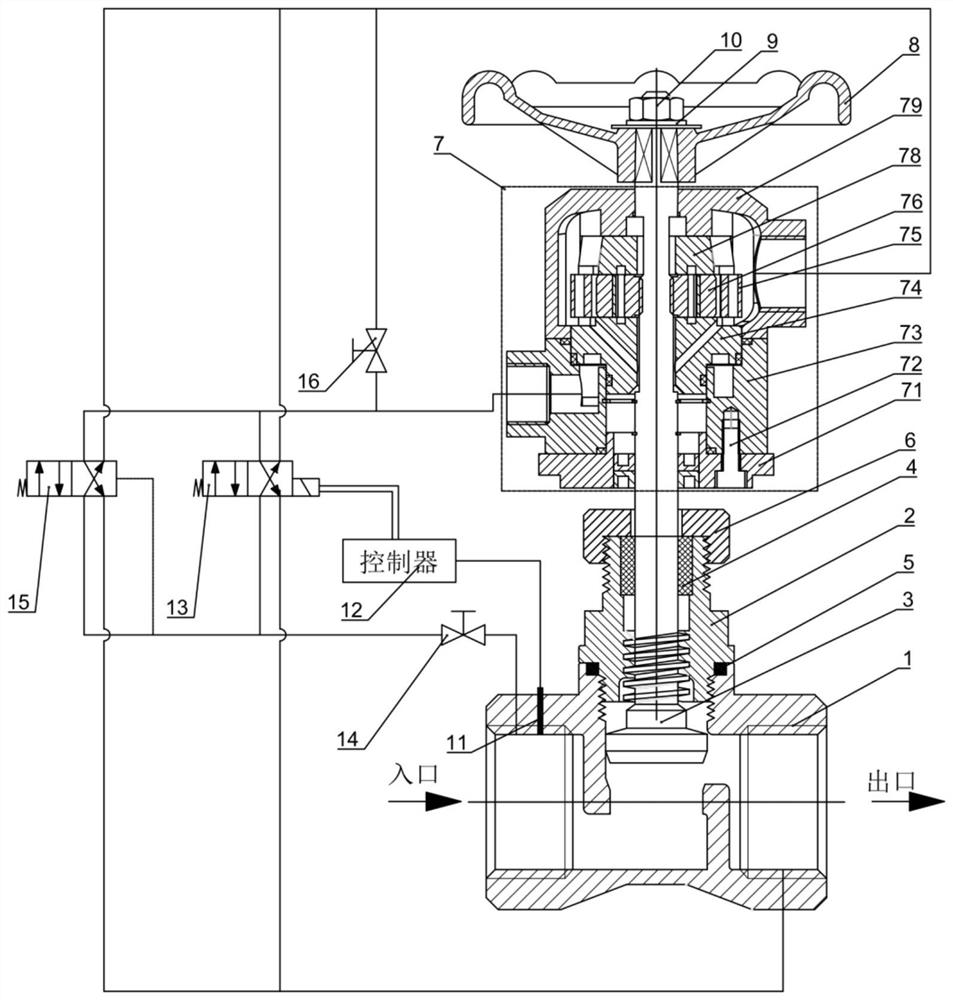

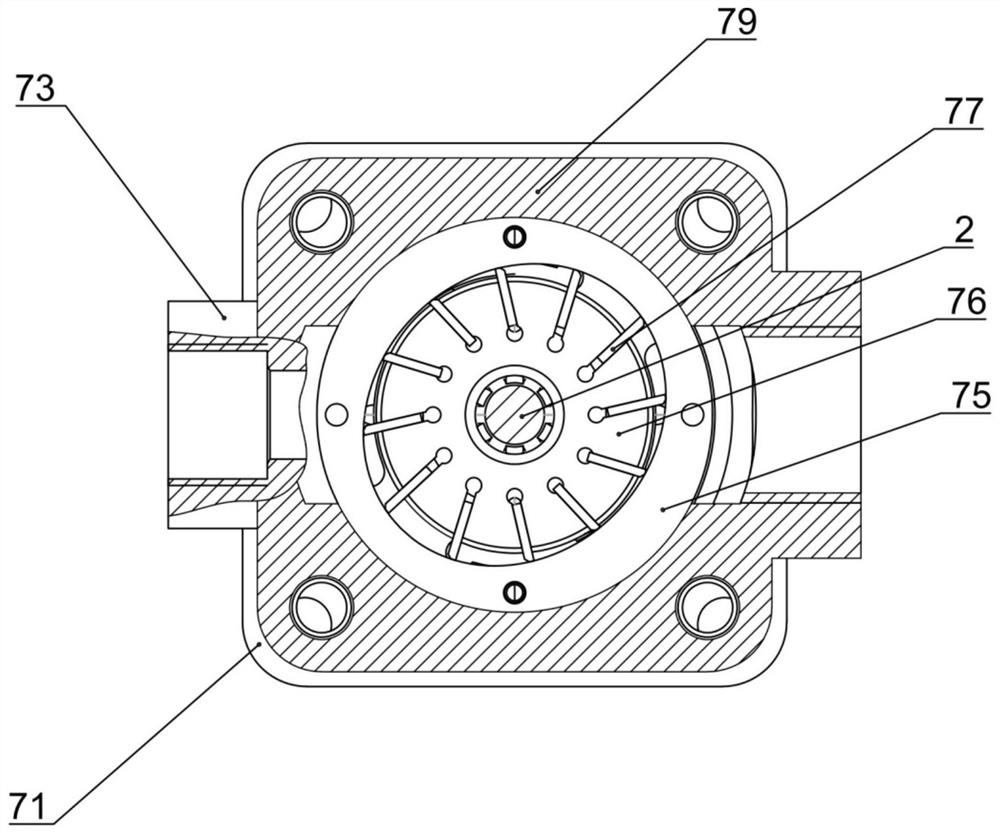

[0032] Embodiment 1: as Figure 1-3 Shown is a multi-redundant electromagnetic pilot-operated safety water hammer pressure relief valve directly driven by a vane motor.

[0033] refer to figure 1 , the water hammer pressure relief valve includes a hand wheel 8, a vane motor 7, a sealing end cover 6, a support cylinder 2, an electromagnetic pilot valve 13, a mechanical pilot valve 15, a controller 12 and a main valve body 1; the bottom of the hand wheel 8 is provided with a special-shaped Externally threaded plug 3, one end of the special-shaped externally threaded plug 3 passes through the vane motor 7, the support cylinder 2, and the sealing end cover 6 from top to bottom, and extends into the main valve body 1 and seals with the main valve body 1; One end of the support cylinder 2 engages with the special-shaped external thread plug 3 through the internal thread; the vane motor 7 is used to drive the special-shaped external thread plug 3 to rotate.

[0034] The angle betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com