Control method of air cooling equipment and air cooling equipment

A control method and air-cooling technology, applied in lighting and heating equipment, coolers, household refrigeration devices, etc., can solve the problems of complex structure design, mutual cooling, cumbersome production process, etc., and achieve simplification and simplification of structure design and process. Structure and process design to achieve the effect of constant temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

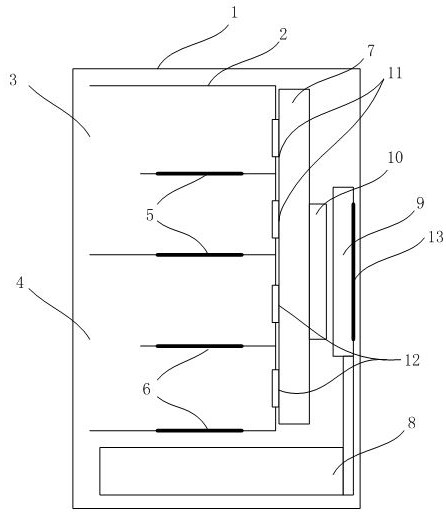

[0022] The air-cooling equipment that the present invention proposes, as figure 1 As shown, it includes a box body 1 and an inner bag 2, the inner bag 2 is installed in the box body 1, and the inner cavity is divided into a first room 3 and a second room 4, and the first room 3 is installed with a first Heating wire 5, the second heating wire 6 is installed in the second chamber 4; the air-cooled equipment adopts a single-cycle refrigeration system to realize refrigeration, and the single-cycle refrigeration system includes a circulating air duct 7, a compressor 8 and an evaporator 9, and is set On the rear side outside the inner tank 2; an evaporating fan 10 is also arranged on the outer rear side of the inner tank 2, and a defrosting sensor (not shown) for detecting the defrosting temperature is installed on the evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com