A highly robust thermal gradient directional harvesting device

A high robustness, thermal gradient technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as low efficiency, difficult practical application, and inability to realize thermal energy collection and conversion methods. , to achieve the effect of large heat conduction speed, conduction and conversion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

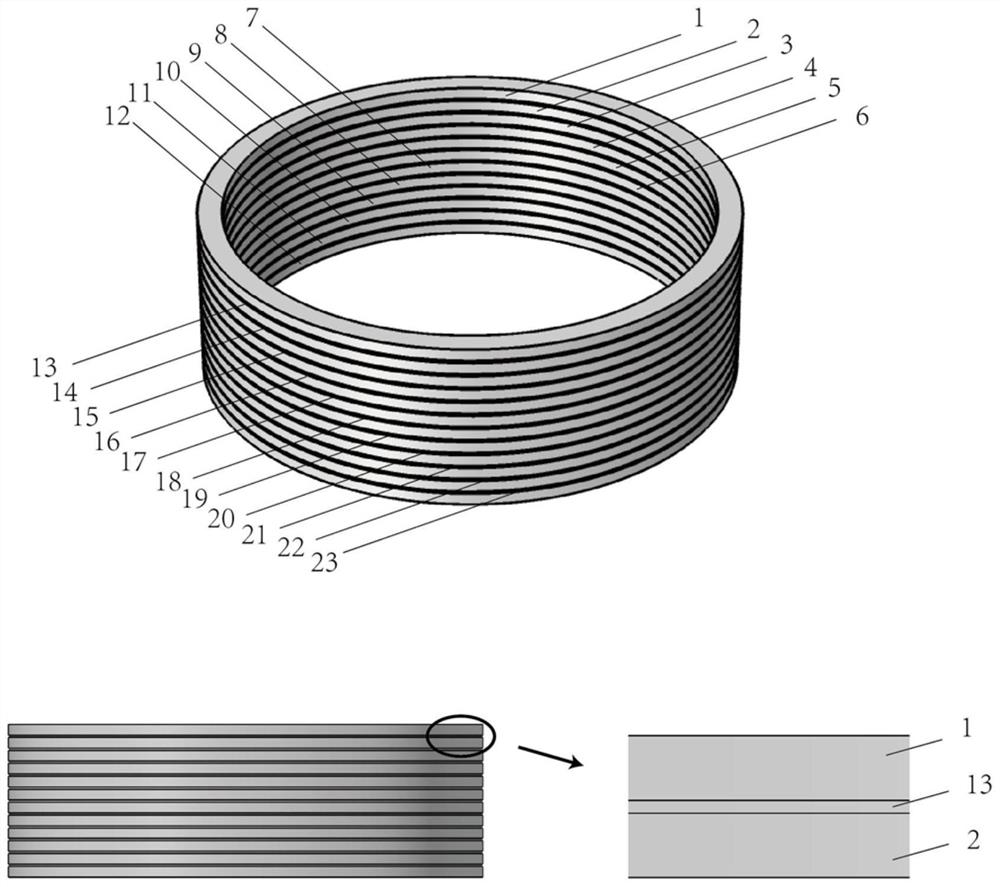

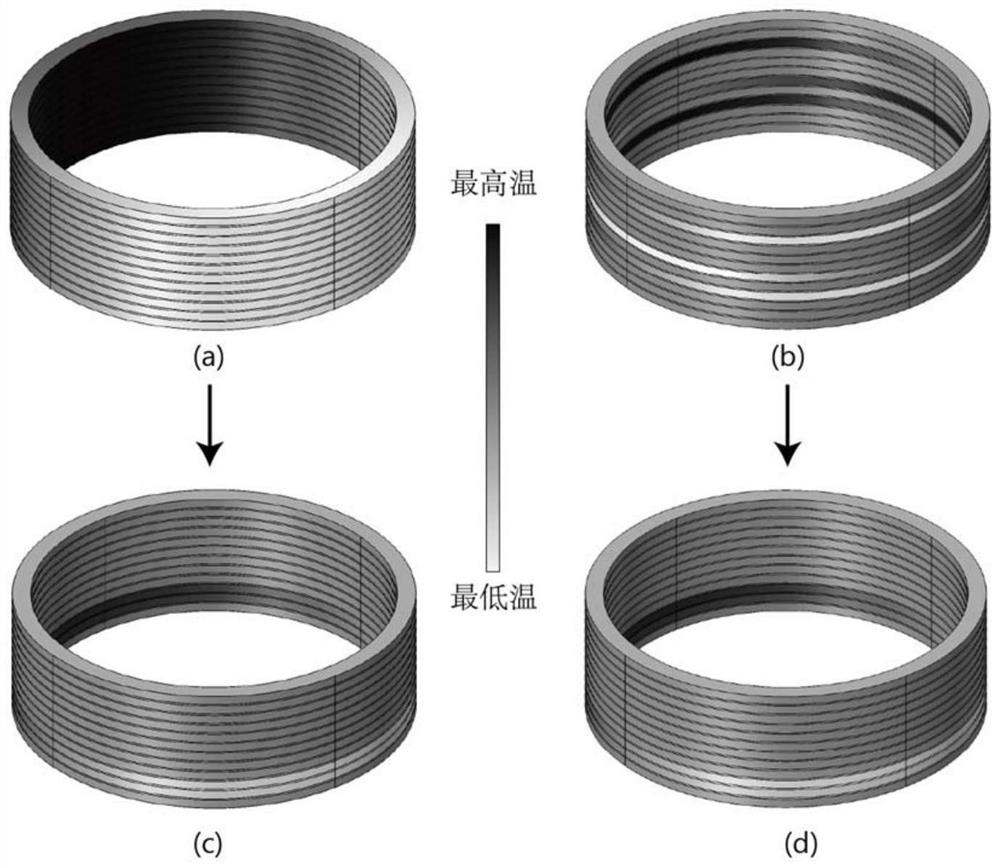

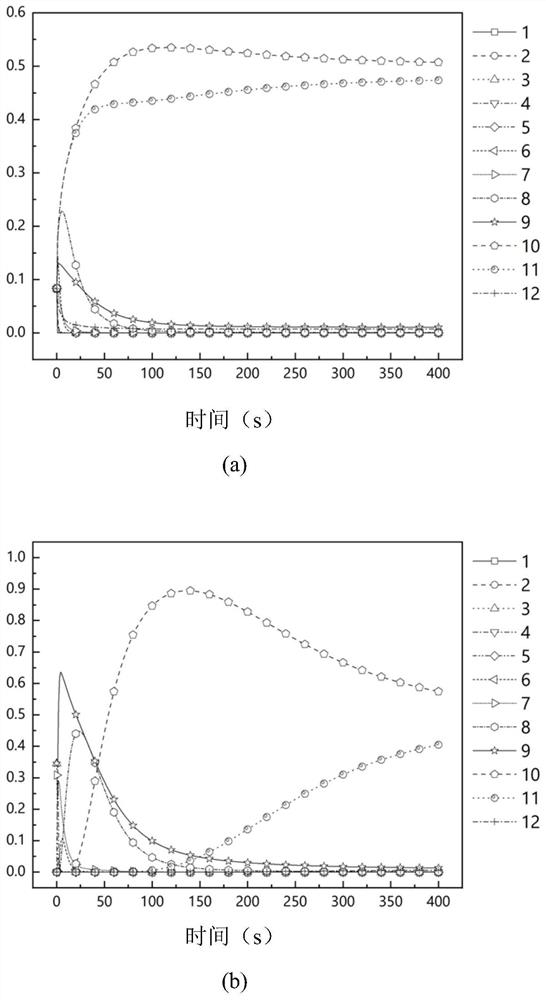

[0075] In this example, see figure 1 As shown, the thermal gradient directional collection device is a multi-layer cylindrical structure composed of twelve ring structures and eleven ring-shaped interface medium layers. All the ring structures and the interface medium layer in the whole thermal gradient directional collection device are coaxially arranged, and a layer of interface medium layer is sandwiched between any two adjacent ring structures.

[0076] Therefore, in this device, the number of asymmetric coupling units actually contained in the first SSH model coupling linear chain and the second SSH model coupling linear chain is 5 and 1 respectively, that is, N=5, M=1. The first layer of ring structure, the first layer of interface medium layer and the second layer of ring structure constitute the first asymmetric coupling unit of the coupled linear chain of the first SSH model, and the subsequent asymmetric coupling units are deduced by analogy; the eleventh layer The ...

Embodiment 2

[0094] In this example, see Figure 4 As shown, the thermal gradient directional collection device is a multi-layer cylindrical structure composed of four ring structures and three ring-shaped interface medium layers. All the ring structures and the interface medium layer in the whole thermal gradient directional collection device are coaxially arranged, and a layer of interface medium layer is sandwiched between any two adjacent ring structures.

[0095] Therefore, in this device, both the first SSH model coupling linear chain and the second SSH model coupling linear chain actually contain one asymmetric coupling unit. The first layer of ring structure, the first layer of interface medium layer and the second layer of ring structure constitute the first SSH model coupling linear chain, the third layer of ring structure, the third layer of interface medium layer and the fourth layer of ring structure The second SSH model coupling linear chain is formed, and the second interfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com