Bending detection method for bar steel material

A detection method and technology for steel materials, applied in the field of computer vision and image detection, can solve problems such as damage to conveying equipment, waste of time and manpower and material resources, equipment failure and damage, and achieve the effect of avoiding subsequent accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

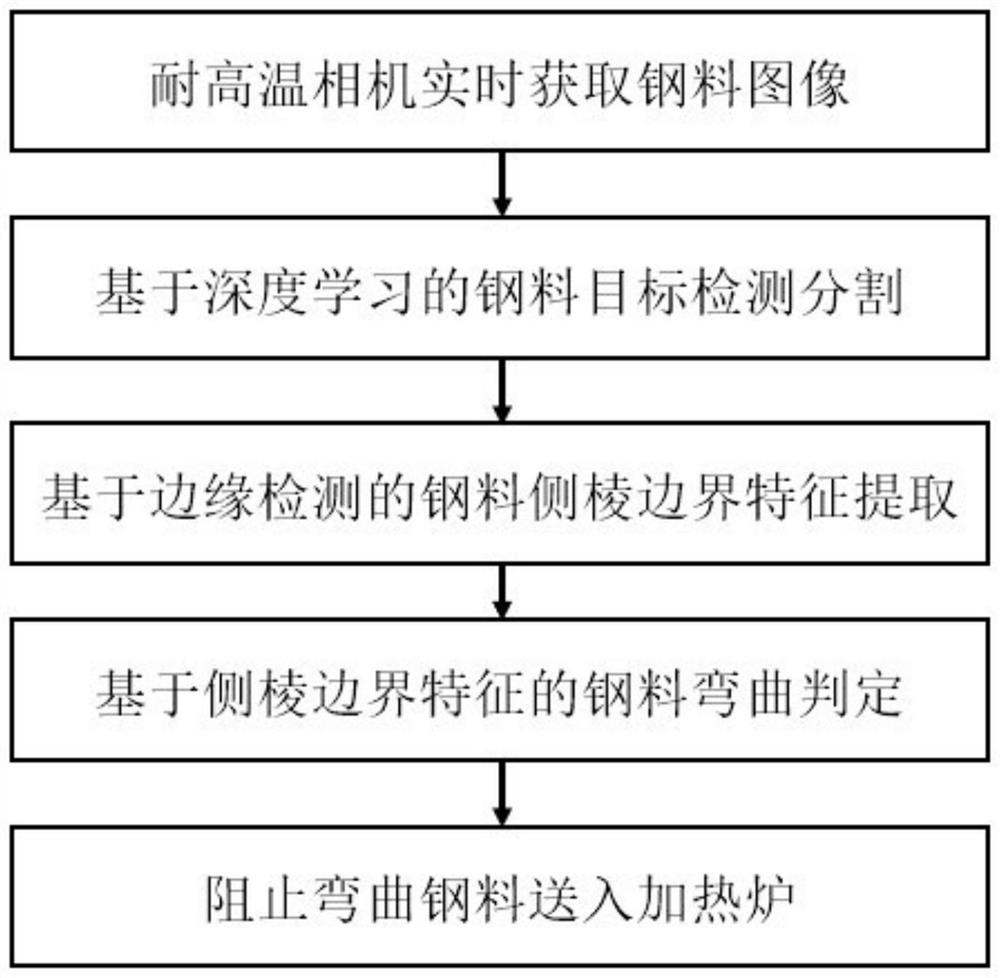

[0040] Such as figure 1 As shown, the present invention is a kind of bar steel bending detection method, comprises the following steps:

[0041] Step S1: Fix a high-temperature-resistant network camera above the bar and steel to collect images of the steel on the conveyor belt in real time;

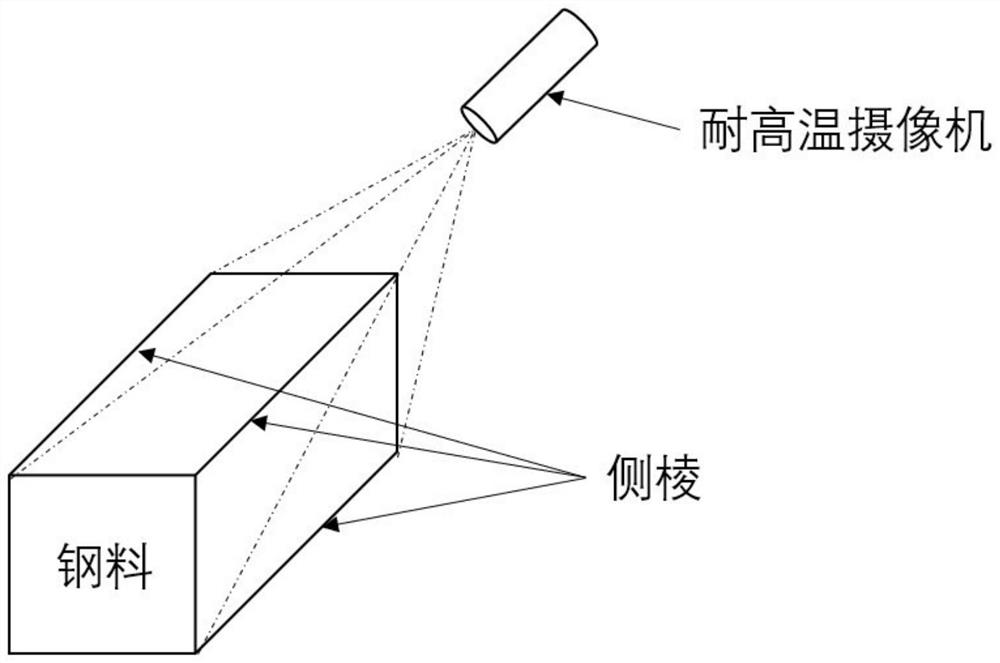

[0042] Since the detection environment is located next to the heating furnace, the ambient temperature is relatively high. In order not to affect the image collection effect, the DS-NXCN3A204 CMOS starlight-grade high-temperature resistant air-cooled cylindrical network camera is used to collect images. When the steel material is bent, there will be at least one surface (two side edges) are bent, so it is only necessary to detect three of the four side edges to determine whether the steel material is bent. edge) can be completely located within the field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com