A kind of multi-strand wire harness cable preparation and processing method

A processing method and multi-strand wire technology, which is applied in the manufacture of wire harnesses, cable/conductor manufacturing, conductor/cable supply devices, etc., can solve the problems of untightened wire harnesses, easy cross-knotting at the junction of wire harnesses, and twisted wire harness springback and other problems, to achieve the effect of improving replacement efficiency, avoiding cross-knotting, and preventing springback of wire harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

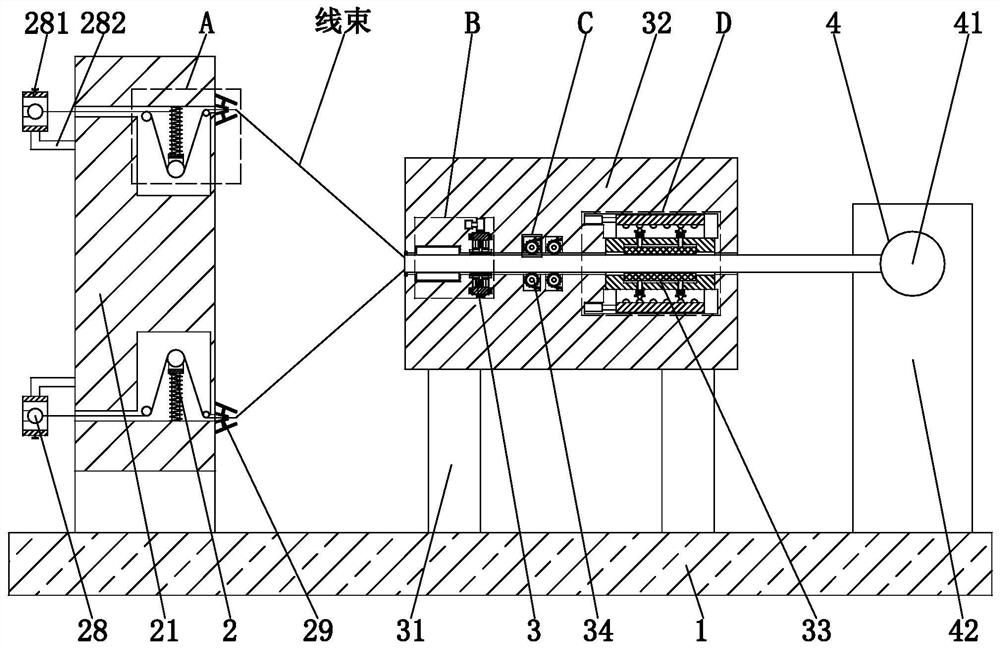

[0038] Embodiments of the present invention will be described below with reference to the accompanying drawings. During this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the lines or the size of the components in the illustrations.

[0039] In addition, the following terms are defined based on the functions in the present invention, and may be different depending on the user, the operator's intention, or convention. Therefore, these terms are defined based on the entire content of this specification.

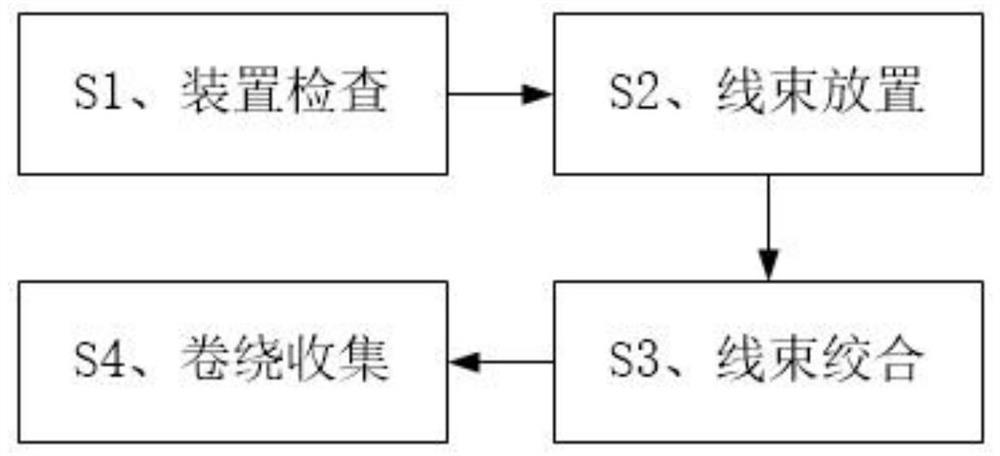

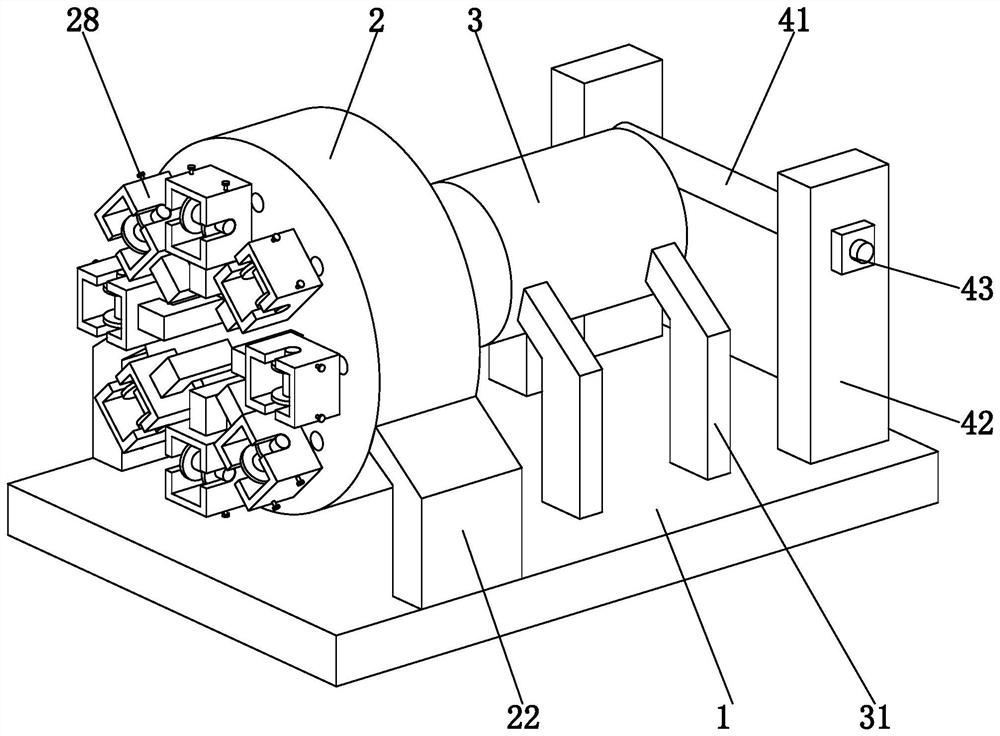

[0040] like Figure 1 to Figure 11 As shown, a multi-strand wire harness cable preparation and processing method, which uses a multi-strand wire harness cable preparation and processing device, the device includes a base 1, a pay-off auxiliary mechanism 2, a twisting mechanism 3 and a collection and winding mechanism 4, using The specific methods of the above-mentioned multi-strand wire harness cable preparation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com