Method for determining lamination height of stator core sections of permanent magnet direct-driven wind driven generator

A permanent magnet direct drive, stator core technology, used in electromechanical devices, electrical components, magnetic circuit static parts, etc., can solve the problem of uneven temperature distribution in the axial direction of the stator, prevent core warpage, ensure reliable operation, The effect is evenly distributed along the axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

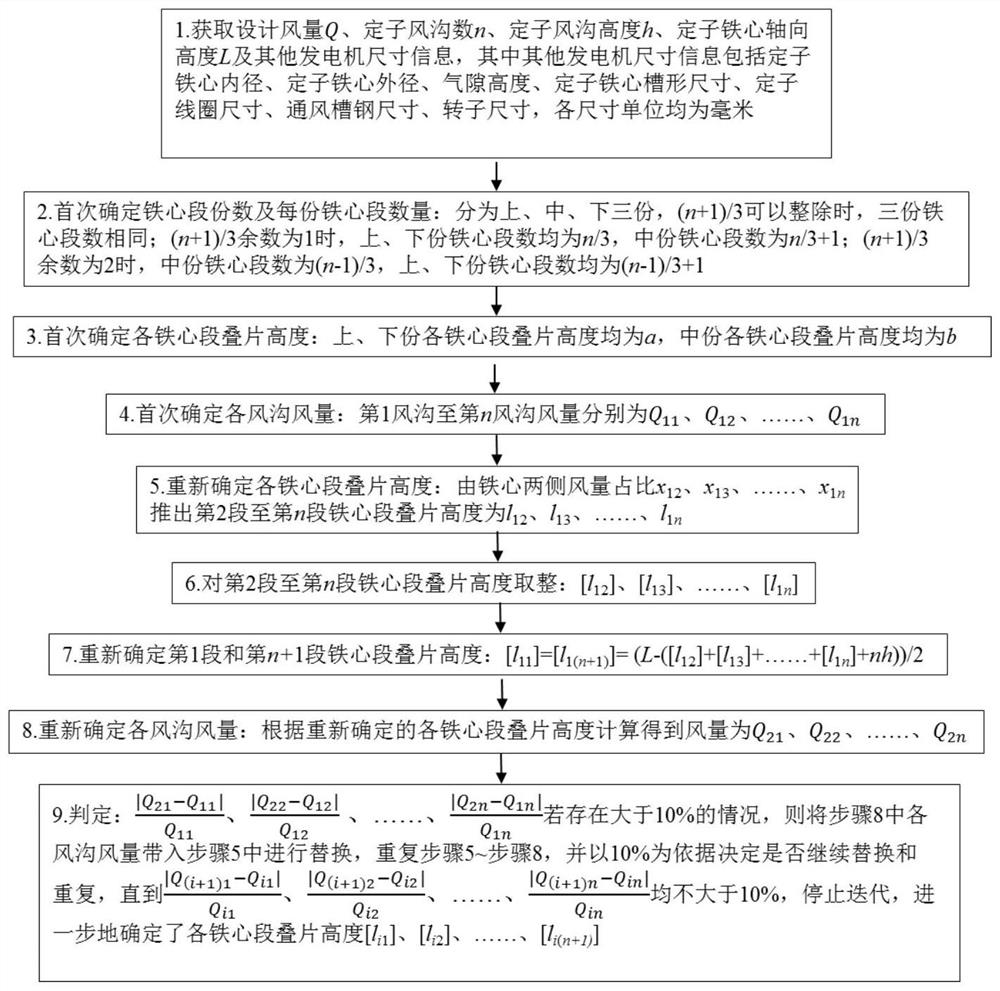

[0020] The implementation of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

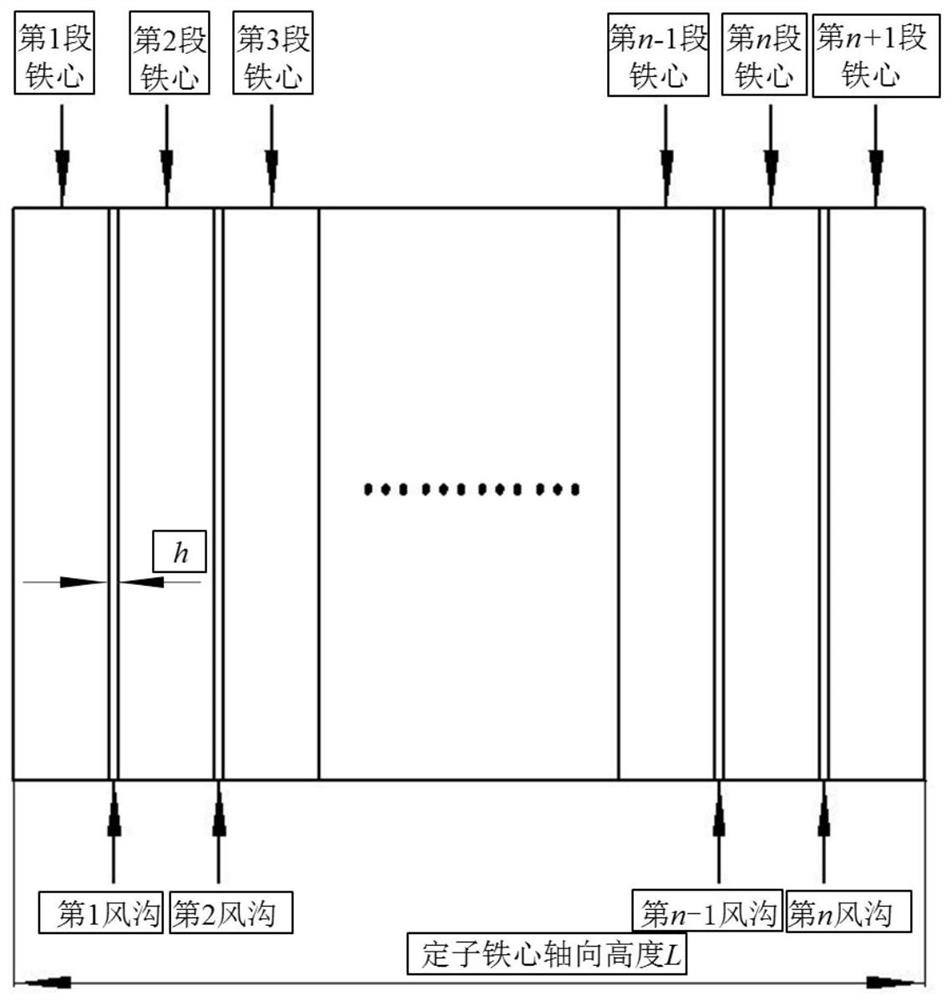

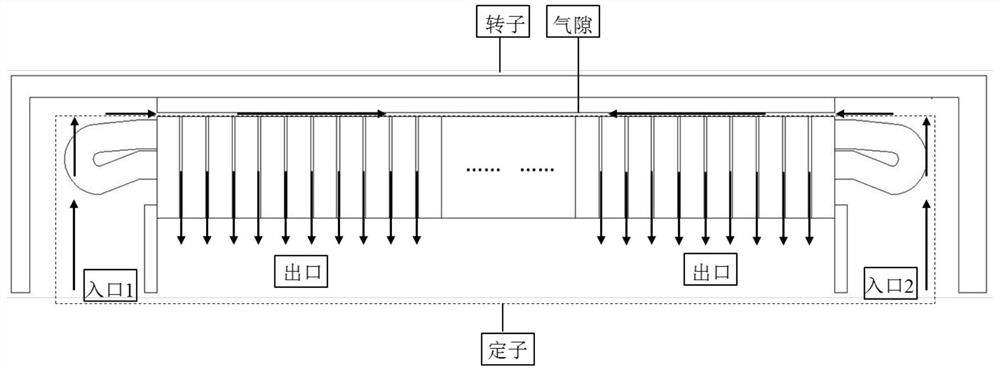

[0021] The present invention mainly relates to a method for determining the lamination height of the stator core section of a permanent magnet direct drive wind power generator, the design air volume Q, the number n of stator air channels, the height h of stator air channels, the axial height L of the stator core and other dimensions of the generator The acquisition of information is not the scope of the present invention. The present invention assumes that before determining the lamination height of the stator core section, when designing a permanent magnet direct-drive wind power generator, the design air volume Q, the number of stator wind grooves n, the height of the stator wind groove h, the axial height L of the stator core and other The generator size information has been obtained, and other generator size information includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com