A tool for automatic bending of galvanized steel pipe and its application method

A galvanized steel pipe, automatic technology, applied in the field of building construction, can solve the problems of difficult management, economic loss, lack of pipe bending tools, etc., and achieve the effect of convenient operation, simple operation and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

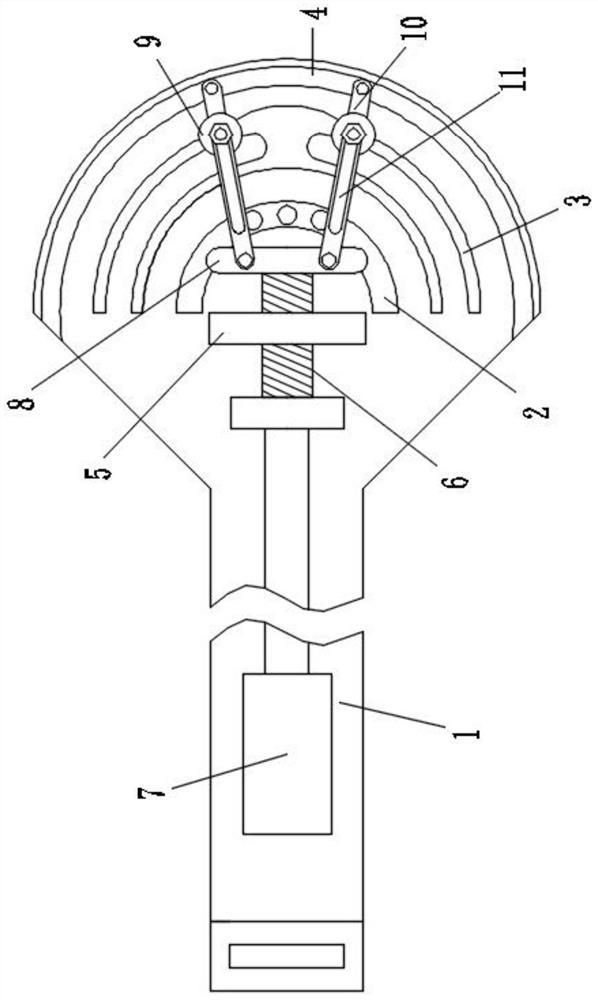

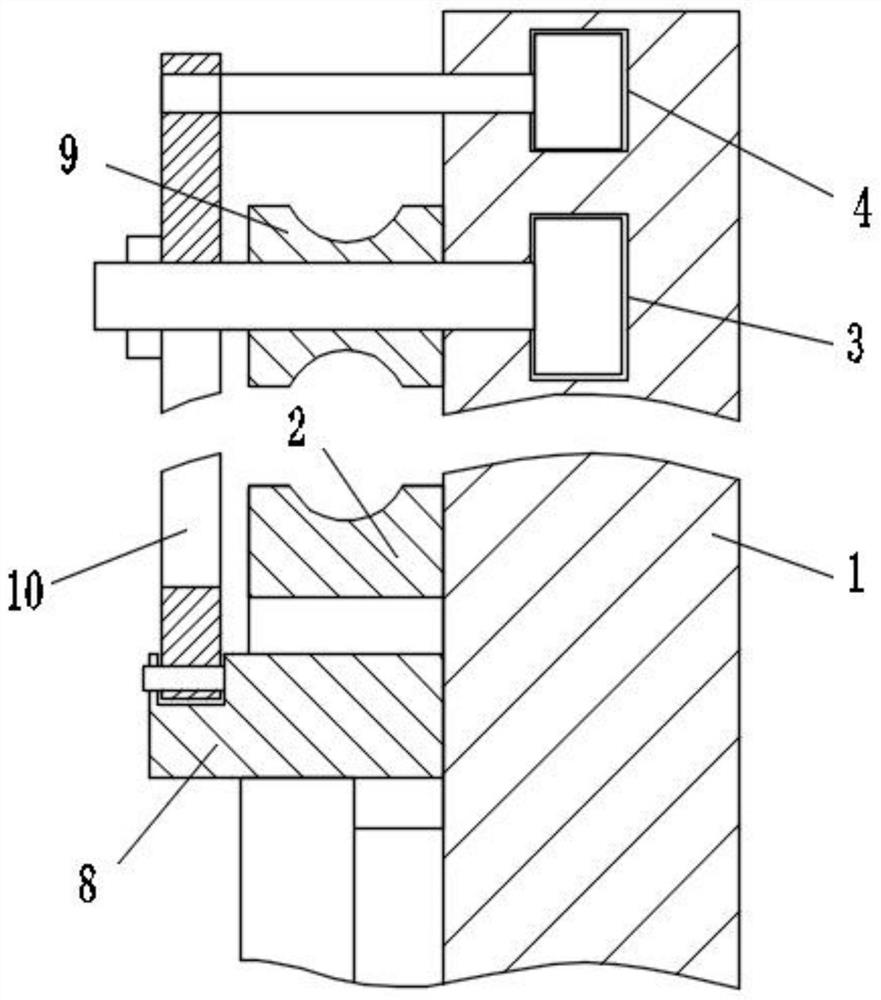

[0026] Such as figure 1 and image 3 As shown, a tool that facilitates automatic bending of galvanized steel pipes includes a body 1 with a hand-held portion, and the body 1 is provided with a forming portion 2, a positioning piece 5, a guide groove 2 4 and a plurality of guide grooves 1 3, A transmission screw 6 is rotatably installed on the positioning member 5, a connector 8 is rotatably installed on one end of the transmission screw 6, and a driver 7 is connected to the other end (the motor and the connecting rod connected to the output end and used to connect the transmission screw 6) , the driver 7 is installed close to the hand-held part, and two guide rods 10 arranged in a figure-eight shape are rotatably installed on the connector 8, and the end of the guide rod 10 away from the connector 8 is movably arranged in the guide groove 2 4 Inside, the two guide rods 10 are provided with chute 11, and the inside of the two chute 11 is provided with a pressure member 9 which...

Embodiment 2

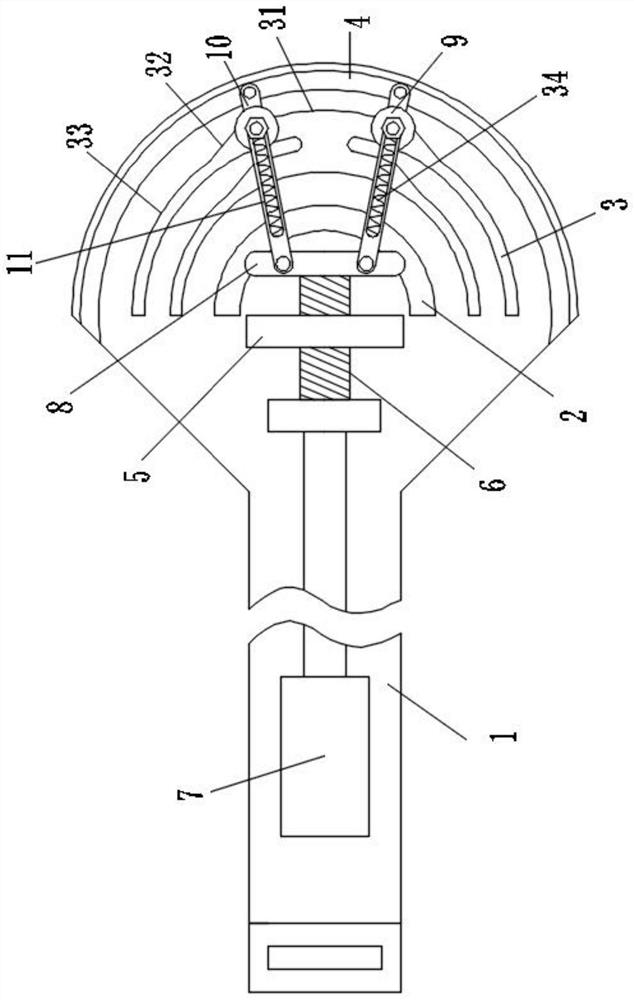

[0035] in such as figure 2 and Figure 4 As shown, the difference from Embodiment 1 is that each of the guide grooves 3 includes a separation part 31, a guide part 32 and a pressurizing part 33, and the two ends of the guide part 32 are connected with the separation part 31 and the pressurizing part respectively. The part 33 communicates, the side wall of the separating part 31 away from the connecting part 8 is located outside the side wall of the pressurizing part 33 away from the connecting part 8, and the side wall of the separating part 31 close to the connecting part 8 and the pressurizing part 33 is coplanar with the side wall near the connector 8. The setting of the separation part 31 is more convenient to separate the pressure member 9 from the steel pipe. If there is no such setting, the operation will be relatively troublesome.

[0036] In a further preferred solution of the present invention, a flat spring 34 is arranged inside the chute 11 , one end of the fla...

Embodiment 3

[0038] Such as figure 2 and Figure 4 As shown, a method for using a tool that facilitates the automatic bending of galvanized steel pipes includes the following steps:

[0039] Step 1: First adjust the pressure part 9 to be inside the guide groove 13 adapted to the diameter of the steel pipe, then insert the steel pipe between the pressure part 9 and the forming part 2, and between the guide rod 10, the connecting part 8 and the body 1 The steel pipe breaks away from the inside of the area;

[0040] Step 2: Start the driver 7, the driver 7 drives the transmission screw 6 to rotate, and then drives the connecting piece 8 to move outward, the end of the guide rod 10 away from the connecting piece 8 expands to both sides along the guide groove 2 4, and the pressure member 9 also follows the guide rod The rotation of 10 moves along the separation part 31, the guide part 32, and the pressurizing part 33 in sequence, and then applies pressure to the steel pipe to bend and form t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com