Asphalt pavement structure capable of preventing crack propagation and construction method

A technology for asphalt pavement and crack propagation, which is applied to the coagulation pavement, roads, roads and other directions paved on site. Composite bond strength, enhancing integrity and strength, and alleviating the effect of crowding diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

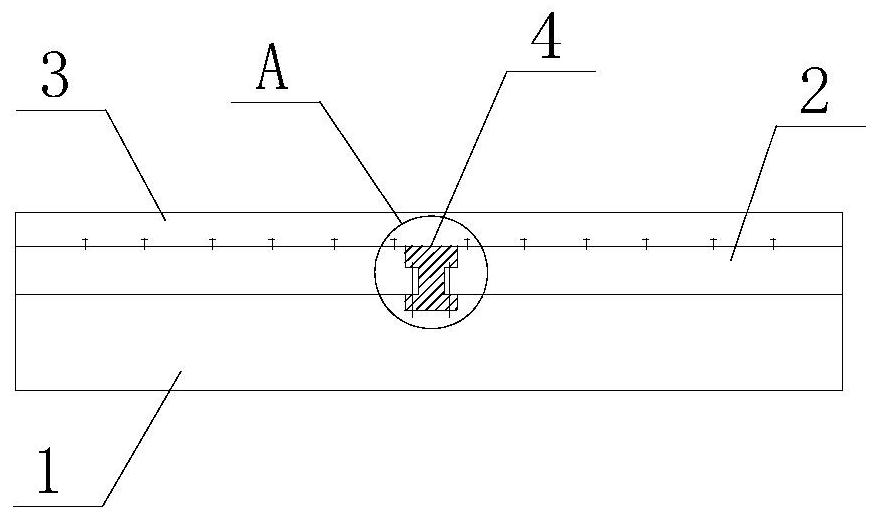

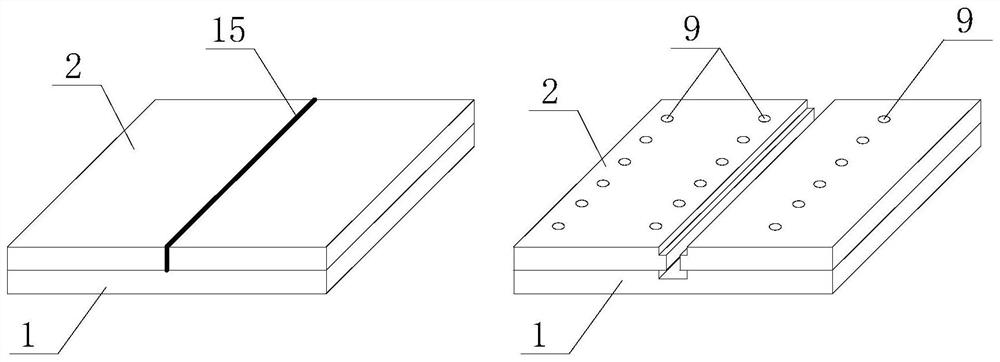

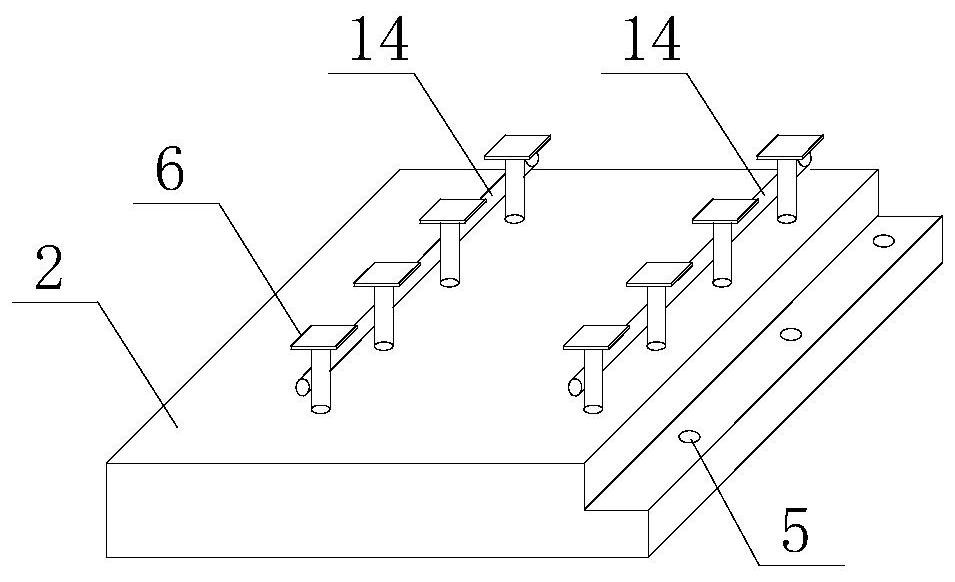

[0063] In this embodiment, the asphalt pavement structure includes a base layer 1, an old surface layer 2 arranged on the base layer 1, and a new surface layer 3 arranged on the old surface layer 2; a gap 15 on the old surface layer 2 Groove at the base layer 1 to form an I-shaped groove, and a seam stop structure 4 is set in the I-shaped groove. A connecting hole 5 for connecting the stopper structure 4 is opened on the old surface layer 2 . The seam stopping structure 4 is composed of an upper plate 10 , a vertical plate 11 and a lower plate 12 . An anti-wrapping device 6 is arranged between the old surface layer 2 and the new surface layer 3; An installation hole 9 for installing a fixing rod 8 is opened on the old surface layer 2 .

[0064] In this embodiment, connecting rods 13 are arranged in the connecting holes 5; the connecting holes 5 are arranged every 65 cm. The connecting rod 13 is a hot-rolled ribbed steel bar with a nominal diameter of 12mm.

[0065] In this...

Embodiment 2

[0080] In this embodiment, the asphalt pavement structure includes a base layer 1, an old surface layer 2 arranged on the base layer 1, and a new surface layer 3 arranged on the old surface layer 2; a gap 15 on the old surface layer 2 Groove at the base layer 1 to form an I-shaped groove, and a seam stop structure 4 is set in the I-shaped groove. A connecting hole 5 for connecting the stopper structure 4 is opened on the old surface layer 2 . The seam stopping structure 4 is composed of an upper plate 10 , a vertical plate 11 and a lower plate 12 . An anti-wrapping device 6 is arranged between the old surface layer 2 and the new surface layer 3; An installation hole 9 for installing a fixing rod 8 is opened on the old surface layer 2 .

[0081] In this embodiment, connecting rods 13 are arranged in the connecting holes 5; the connecting holes 5 are arranged every 80 cm. The connecting rod 13 is a hot-rolled ribbed steel bar with a nominal diameter of 14 mm.

[0082] In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com