Rotor assembly and self-starting permanent magnet synchronous reluctance motor

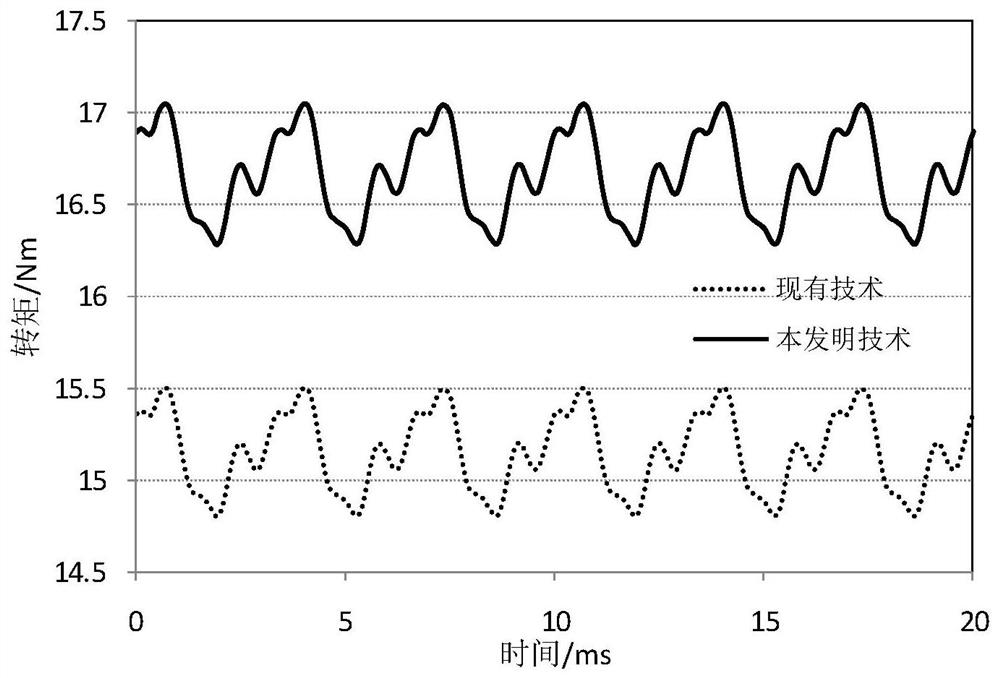

A technology of rotors and components, which is applied to synchronous machine parts, motors, electric components, etc., can solve the problems of limiting the permanent magnet torque and efficiency of the motor, so as to increase the amount of use, increase the placement space, and improve the efficiency of the motor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

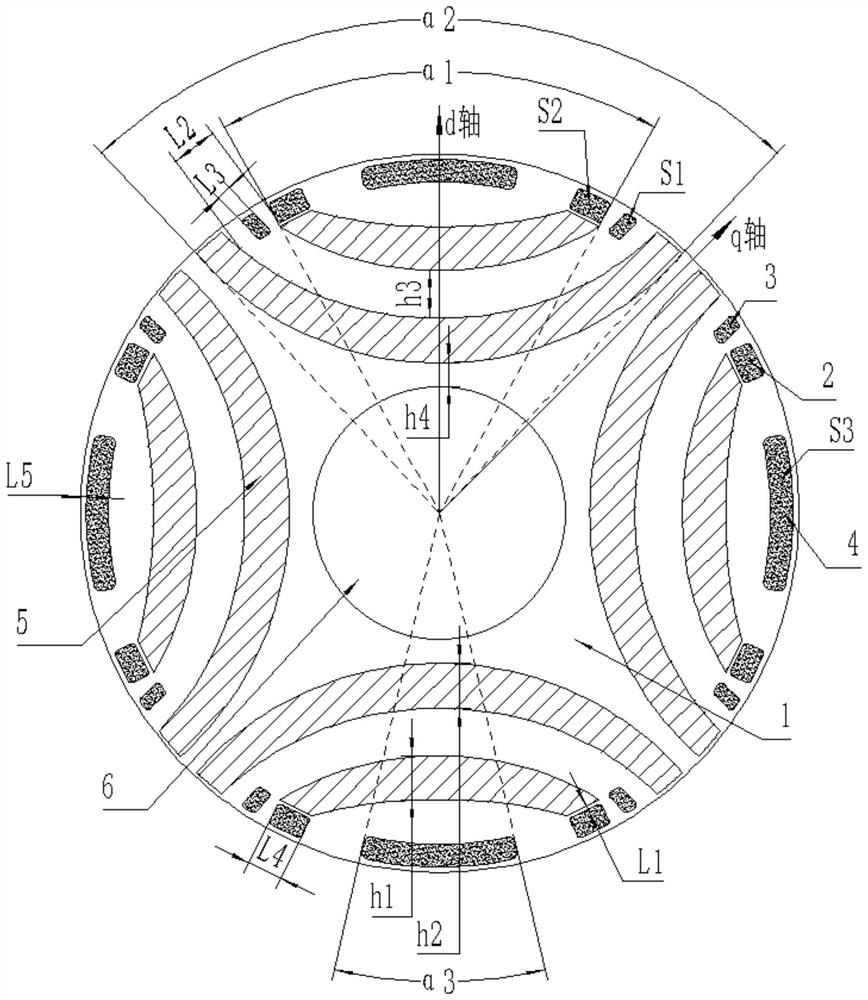

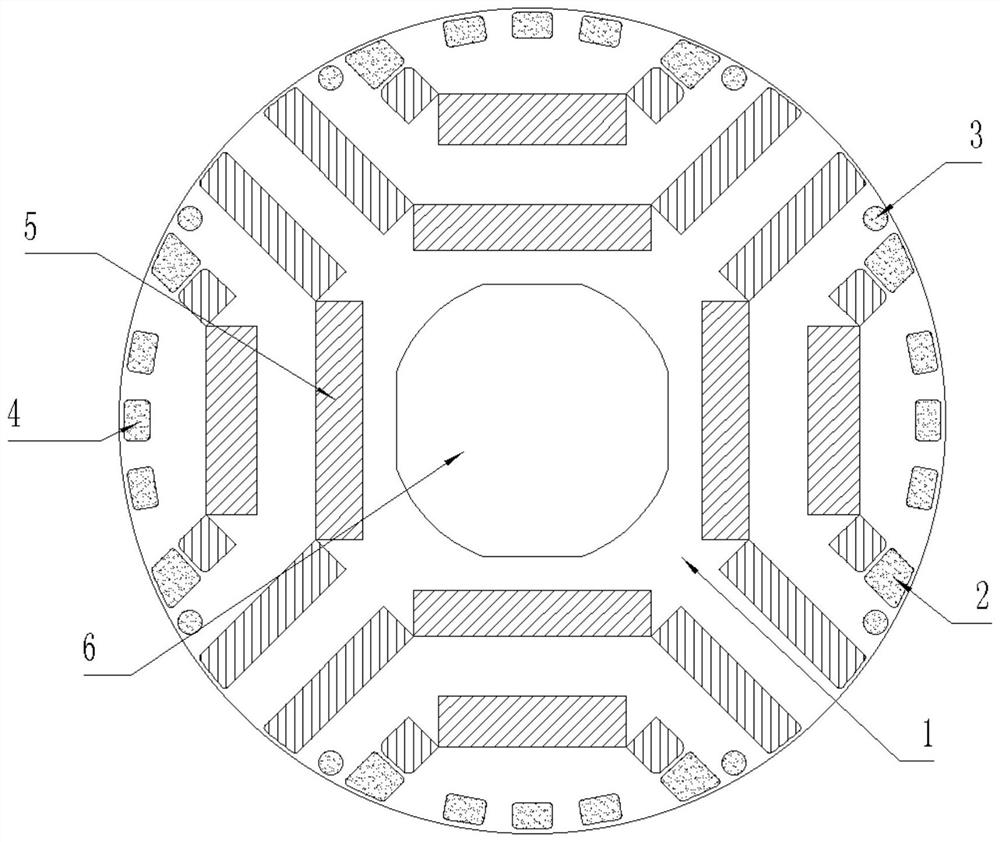

[0031] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the present application, the rotor assembly includes a rotor core 1, and the cross section of the rotor core 1 is provided with a shaft hole 6, a mounting groove, a first filling groove 2 and a dislocation filling groove 3, and the mounting groove is provided with There are permanent magnets 5, and there are at least two layers of permanent magnets 5 arranged along the d-axis direction. The permanent magnets 5 located at the radially innermost side along the d-axis direction extend to the rotor outer circle of the rotor core 1. The first filling groove 2 is arranged along the d-axis direction. The d-axis direction is located at both ends of the radially outermost permanent magnet 5, and the dislocation filling groove 3 is arranged at both ends of the magnetic conduction channel between adjacent permanent magnets 5, and is located between the first filling groove 2 and the permanent magnet 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com