Wool separating and feeding device

A wool and driving device technology, applied in the field of wool separation and feeding device, can solve the problems of low production efficiency, low quality, increased cost, etc., and achieve the effect of improving wool separation and feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

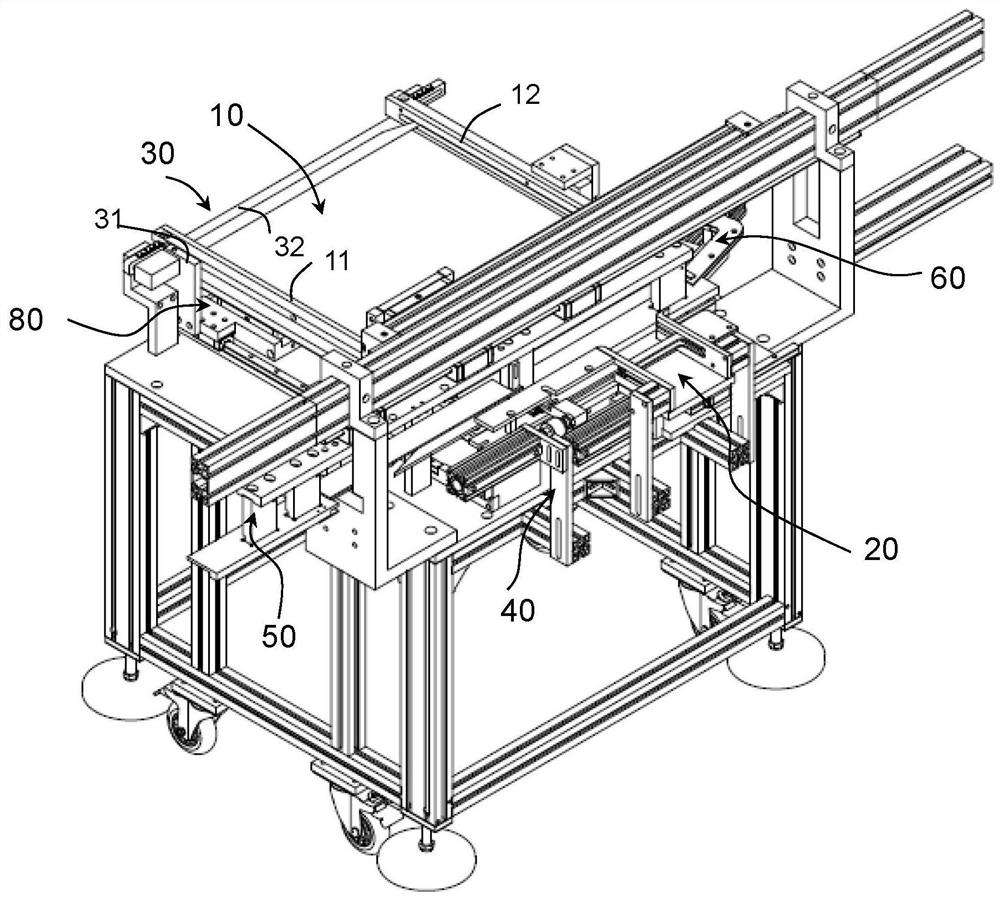

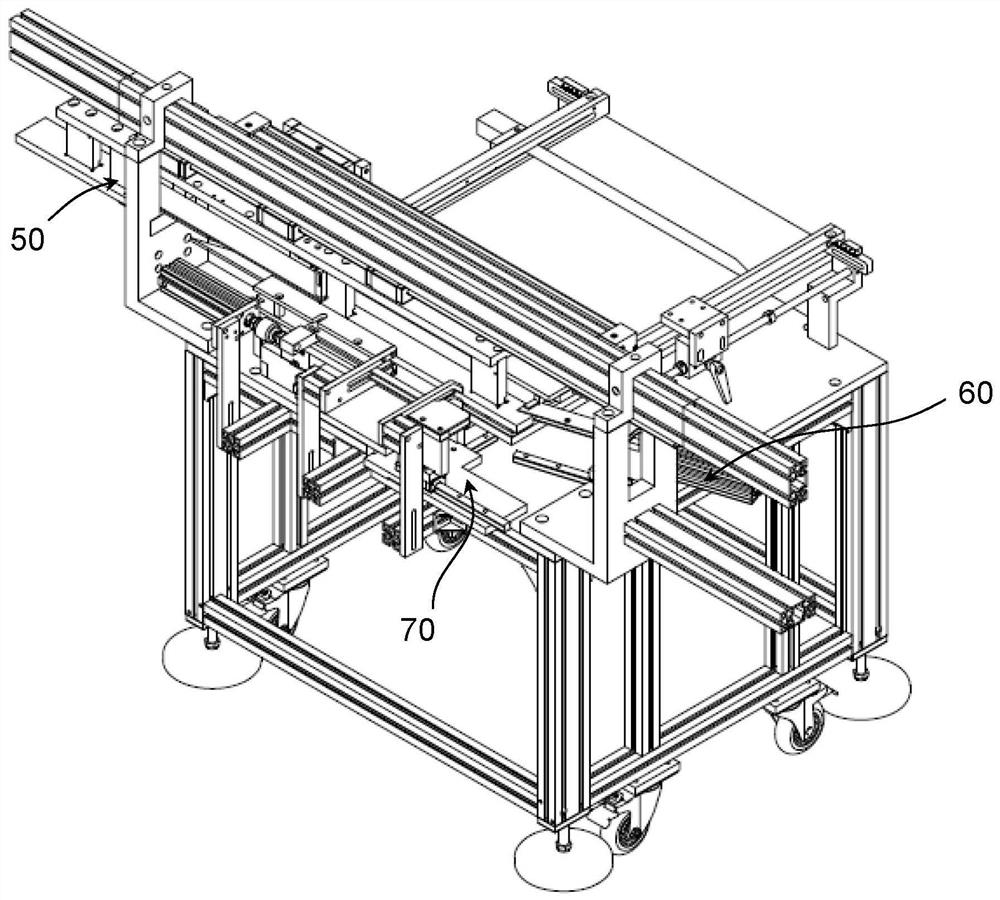

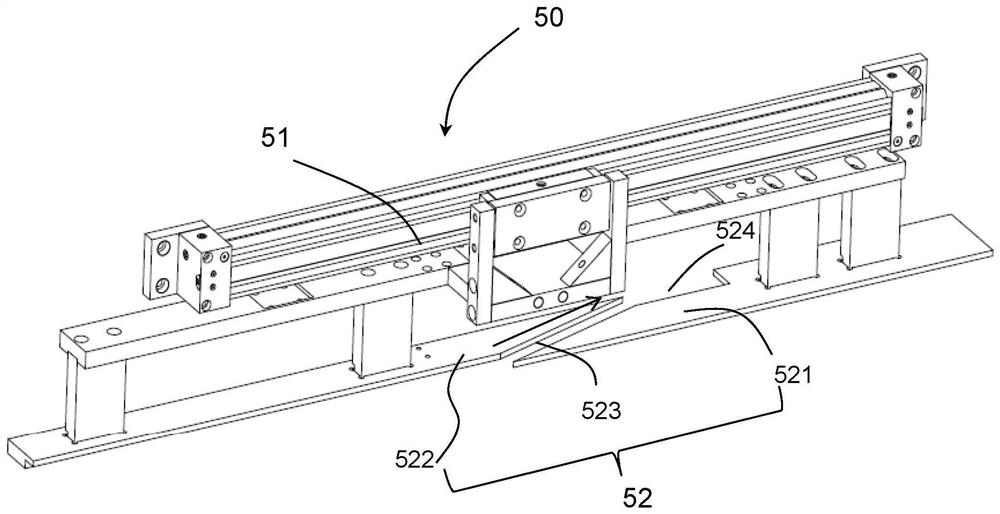

[0059] Please refer to figure 1 , figure 2 As shown, the wool separating and feeding device provided in this embodiment includes a machine platform, a wool loading hopper 10 , a feeding chute 20 , a pressing device 30 , a wool separating device 50 , a wool pushing device 60 and a wool feeding device 70 .

[0060] in:

[0061] The machine platform 10 is formed with a wool storage and storage station, a wool dividing and gathering station and a wool feeding station arranged in sequence along the longitudinal direction.

[0062] Loading wool hopper 10 is arranged at the wool storage and release station place, and the end of wool loading hopper 10 toward the wool dividing and gathering station is the wool loading hopper discharge end, and wool is stored upright in the wool loading hopper 10.

[0063] Feeding chute 20 is arranged at the wool feeding station place, and feeding chute 20 extends along the longitudinal direction, and one end of feeding chute 20 near the wool dividin...

no. 2 example

[0102] The functions realized by the key components included in the wool dividing and feeding device provided in this embodiment are basically the same as those in the first embodiment, so when understanding the structure and working process of the wool dividing and feeding device in this embodiment , reference may be made to the relevant description in the first embodiment and the corresponding accompanying drawings.

[0103] The wool separating and feeding device provided in this embodiment includes a wool loading hopper, a feeding trough, a pressing device, a wool separating device, a wool pushing device and a wool feeding device, wherein:

[0104] The fur loading hopper is used for storing wool, and has a feeding end of the wool loading hopper.

[0105] The feeding chute is used for storing wool from the wool loading hopper, and has a feeding end of the feeding chute.

[0106] The wool separating device is arranged near the discharge end of the wool loading hopper, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com