Deep-hole V-shaped ultrasonic shot blasting device

An ultrasonic shot peening and deep hole technology, which is applied in the direction of used abrasive processing devices, abrasive materials, metal processing equipment, etc., can solve the problems of limited application, and achieve the effect of small equipment, low power consumption, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be used to illustrate the invention without understanding the limitation of the invention. For those skilled in the art, the specific meaning of the above terms can be understood in terms of specific cases.

[0031] In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

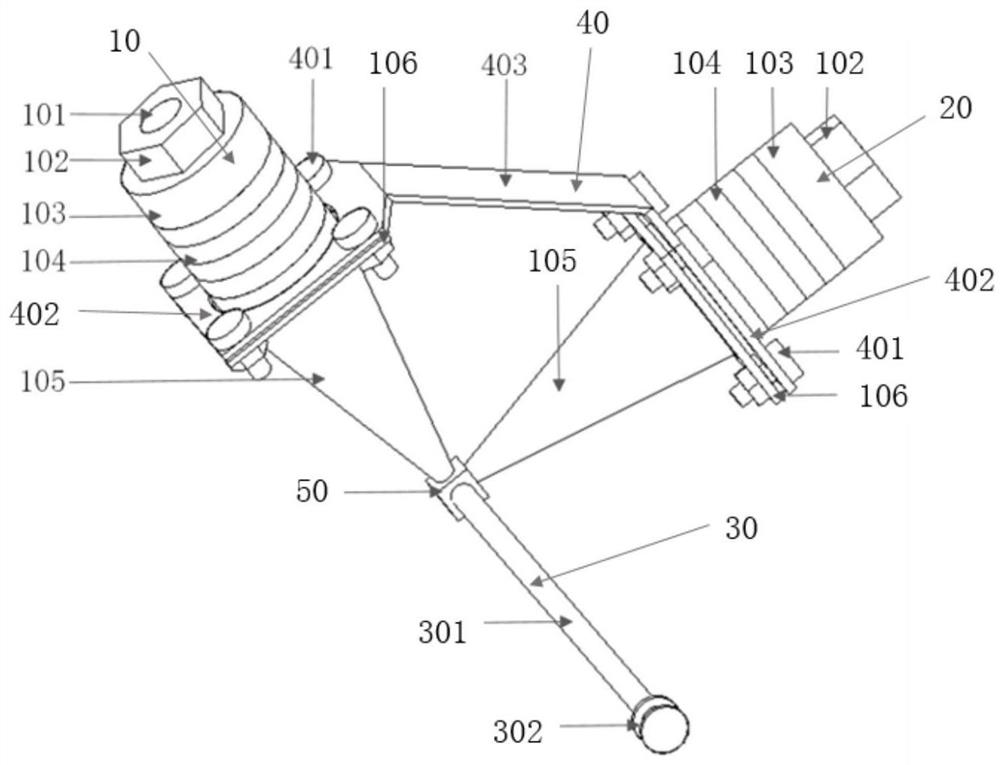

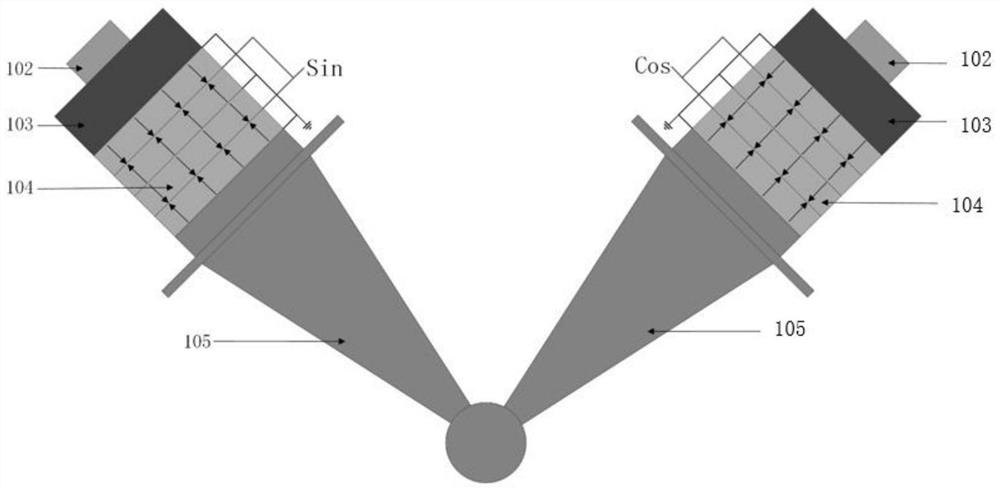

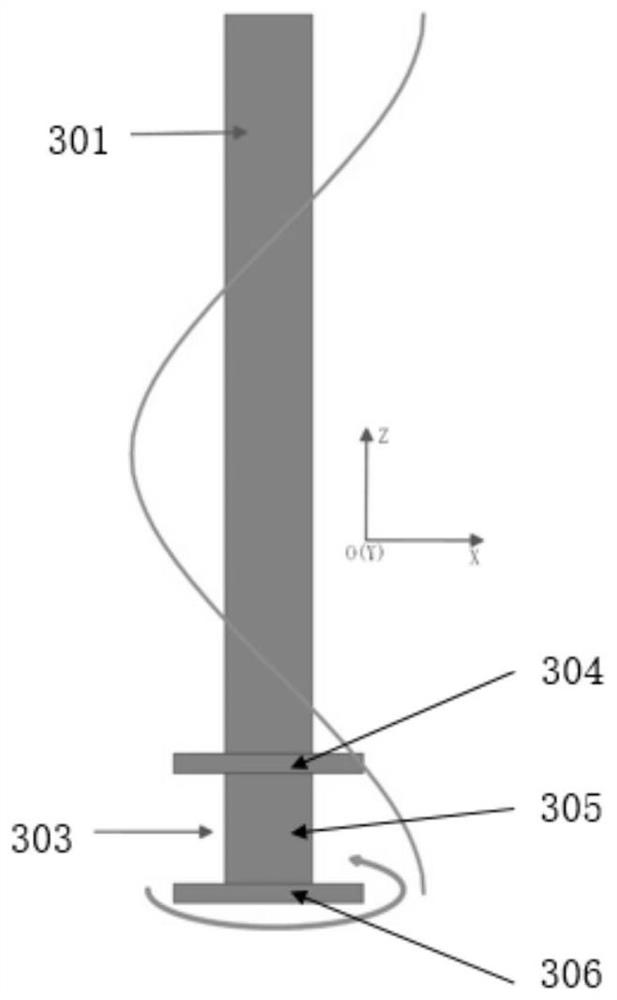

[0032] The present invention is specifically implemented as follows, a deep hole V-type ultrasonic shot fan, the ultrasonic shot device for the inner surface reinforcement treatment, and the ultrasonic shot device can enhance the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com