A design method for oblique riveting clamps of riveting in the closed angle area of aircraft component assembly

A technology for aircraft parts and design methods, applied in the field of aircraft parts assembly tool design, can solve the problems of fatigue fracture of inclined rivets, and achieve the effects of obvious service life, guaranteeing assembly quality, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment takes the aircraft of a certain model in our company as the research object, and now it is necessary to close the closed angle area (generally, the angle between two adjacent sides on the structure is less than 90°) in the aircraft structure. The area is called the closed angle area) for riveting operation, it is necessary to design the oblique riveting card that conforms to the riveting environment.

[0038] This embodiment proposes a design method for riveting oblique riveting in the closed angle area of aircraft component assembly, which belongs to the technical field of aircraft component assembly tool design, and specifically includes the following steps:

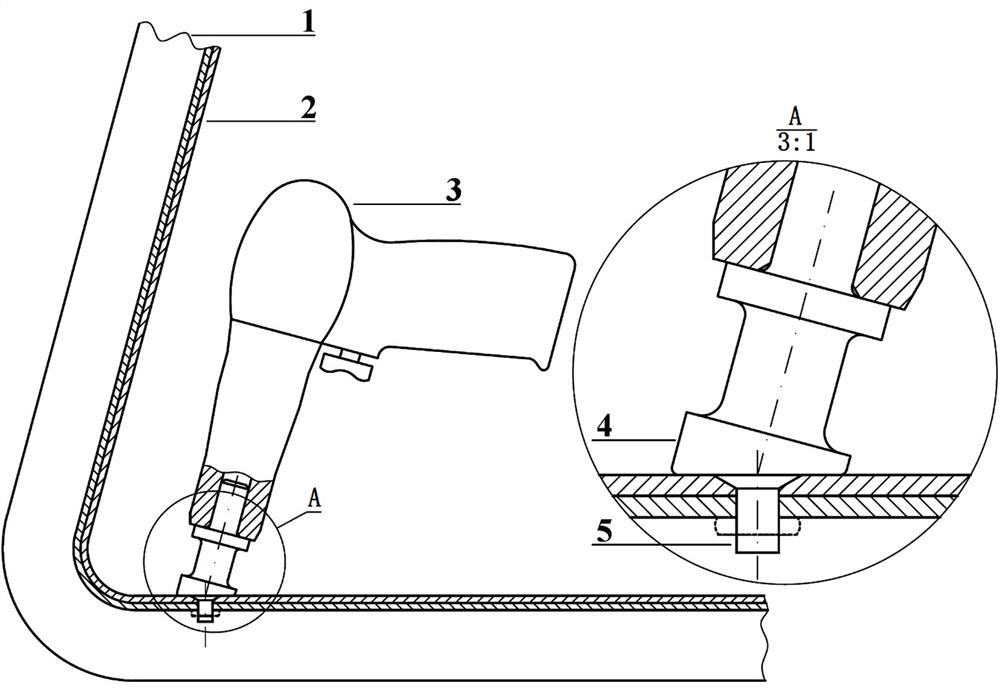

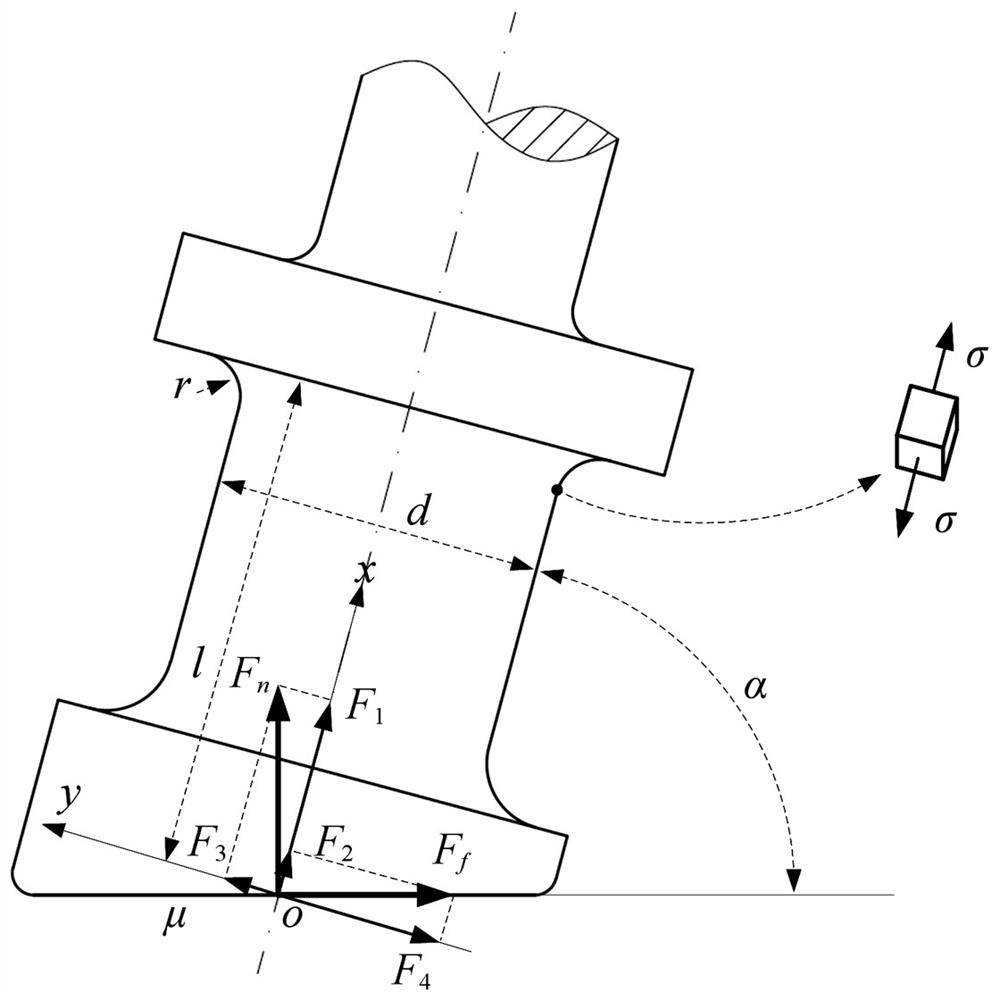

[0039] A. Construct a geometric model according to the structural characteristics of the aircraft's closed corner area. The geometric primitives in the geometric model include bulkheads, skins, rivets, oblique rivets, and rivet guns. Refer to figure 1 , and select the relevant physical feature...

Embodiment 2

[0054] On the basis of Example 1, this embodiment further studies the oblique riveting card, details the design process of this technical solution, provides a basis for the design and manufacturing size of the oblique riveting card, and provides certainty for further research on this technology. It also provides a new design scheme for reference for the manufacture of such tools.

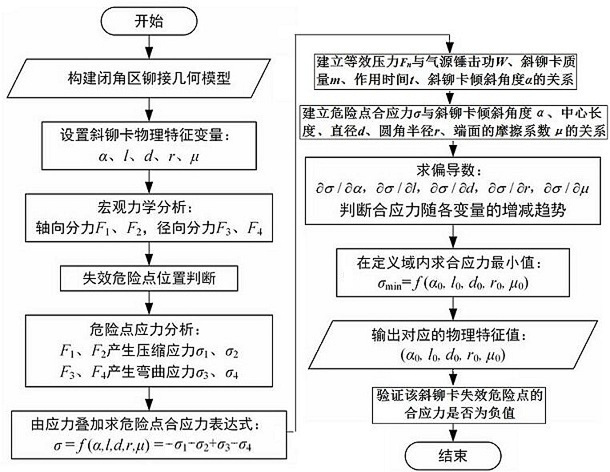

[0055] A method for designing oblique riveting clips for riveting in closed angle areas of aircraft component assembly, belonging to the technical field of aircraft component assembly tool design, referring to image 3 , including the following steps:

[0056] (1) Construct a geometric model according to the structural characteristics of the closed angle area of the aircraft. The geometric primitives in the geometric model include bulkheads, skins, rivets, oblique rivets and rivet guns, and select the relevant geometric primitives Physical characteristics as independent variables, the independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com