Three-dimensional measurement system, method and device, medium and electronic equipment

A three-dimensional measurement and three-dimensional coordinate technology, applied in the field of measurement, can solve the problems of increasing the preparation work for measurement, the influence of measurement accuracy, and the unfavorable system integration of off-axis projection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

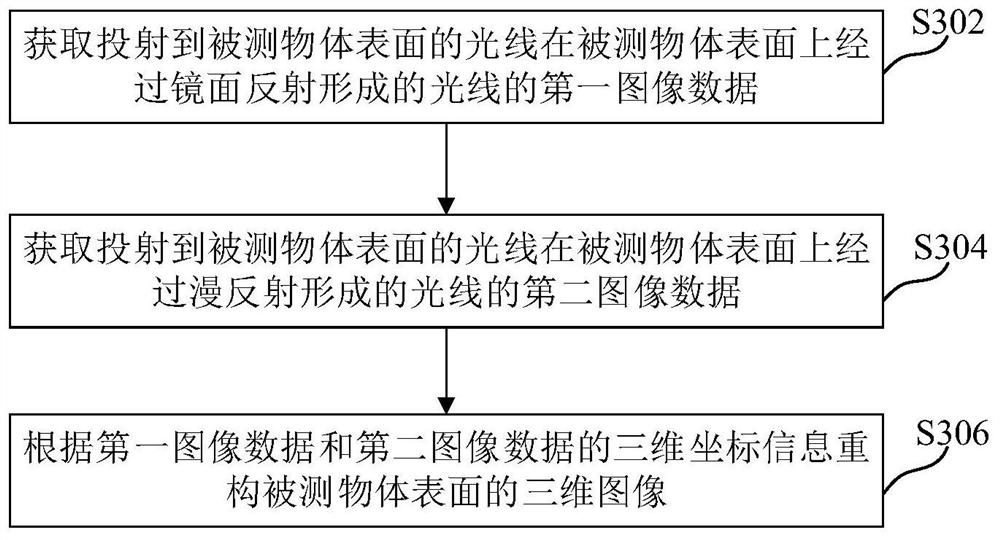

[0050] In the embodiment of the present invention, the first image data and the second image data are obtained by the same image acquisition module collecting the reflected light of the light projected by different structured light projection light sources to the same incident point.

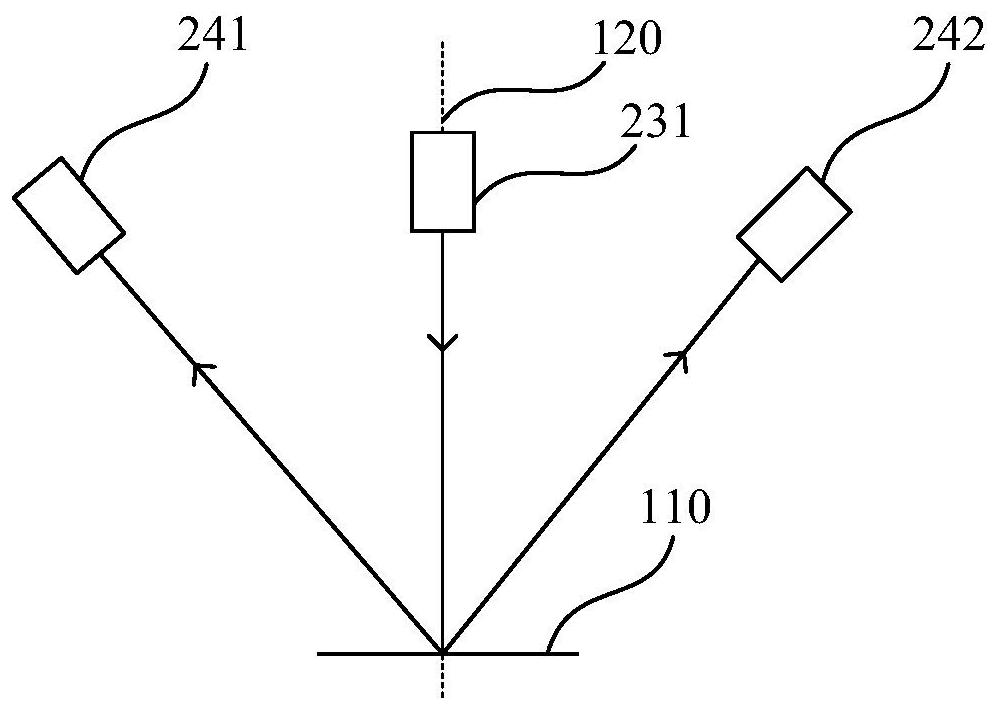

[0051] like Figure 4 As shown, the three-dimensional measurement system provided by the embodiment of the present invention includes: a first structured light projection light source 431; a second structured light projection light source 432, which is arranged on the first normal line perpendicular to the surface of the measured object passing through the first incident point O1 Above: the first image acquisition module 441, configured to acquire the first structured light projection light source 431 and the reflected light from the light projected by the first structured light projection light source 431 to the first incident point O1, wherein the first image acquisition module 441 and the fir...

Embodiment 2

[0062] In the embodiment of the present invention, the first image data and the second image data are obtained by different image acquisition modules collecting the reflected light of the light projected by the same structured light projection light source to the same incident point.

[0063] like Figure 5 As shown, the three-dimensional measurement system of the embodiment of the present invention includes: a third structured light projection light source 531, used to project light onto the second incident point on the surface of the measured object; a second image acquisition module 541, used to acquire the third structure The light projected by the light projection light source to the second incident point is reflected by a specular surface, wherein the second image acquisition module and the third structured light projection light source are symmetrically distributed on both sides of the second normal line 520 to ensure that the third structured light The light projected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com