Full-automatic mechanical visual inspection device for parts

A visual inspection device and machine vision technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low daily output, poor quality stability of daily batch output products, etc., and achieve daily output improvement and quality assurance. Stability Improvement, Effect of Stability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

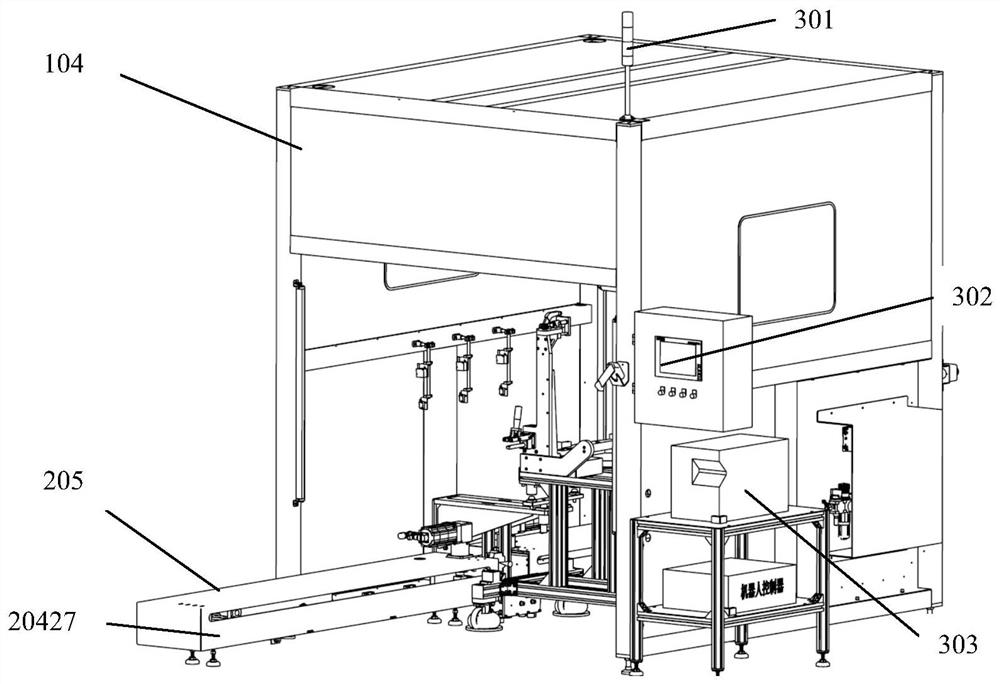

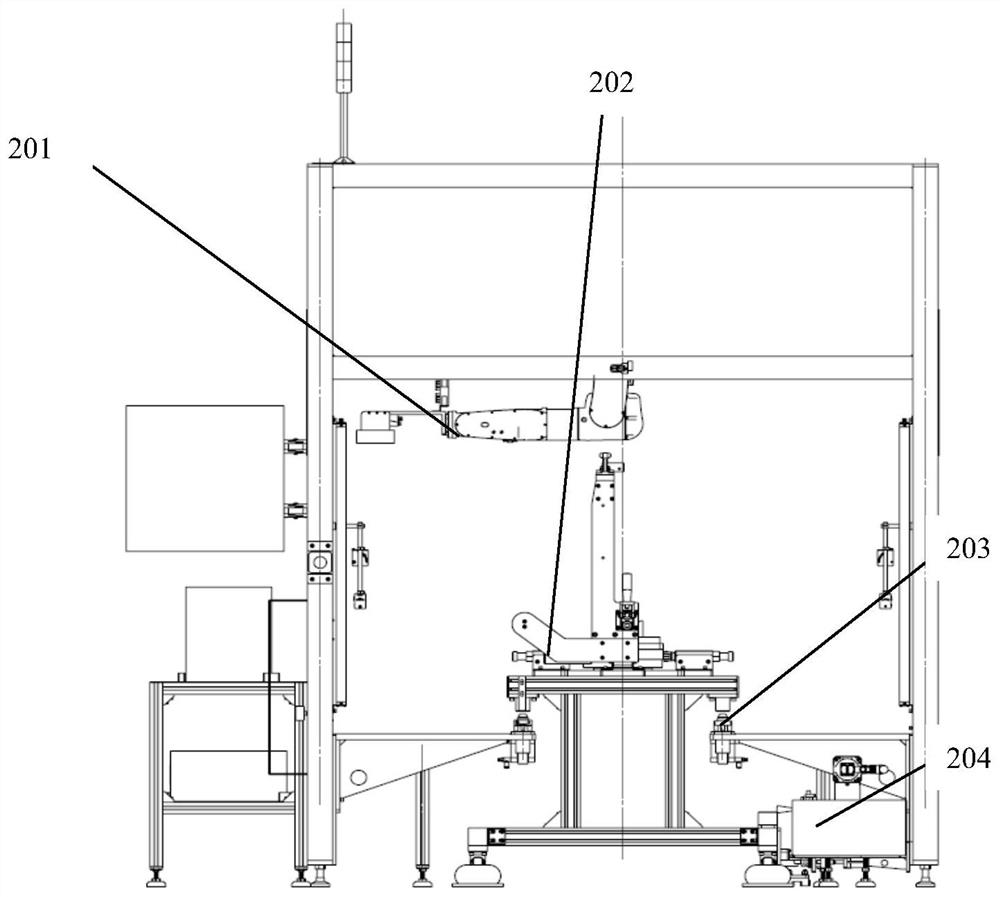

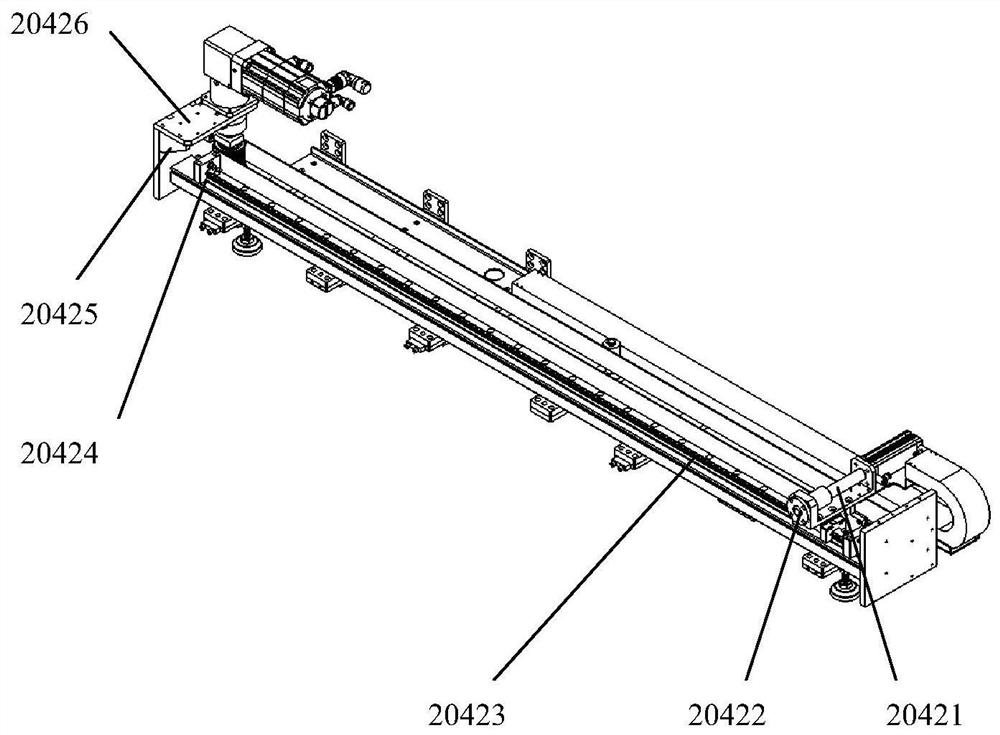

[0034] Such as Figure 1-2 As shown, the present invention provides a fully automatic mechanical vision detection device for parts, including: a detection room 104, a loading and inspection vehicle 202, a drag-in tooling 204, a lifting positioning mechanism 203, a six-axis mechanical arm 201 and a drag-out Tooling 205, wherein the loading and inspection vehicle 202 is used to carry parts to be tested; the dragging tool 204 is set at the entrance of the testing room 104, and is used to drag the loading and testing vehicle 202 into the testing room 104; the lifting positioning mechanism 203 is set in the testing room Inside 104, it is used to lift the loading and inspection vehicle 202; the six-axis mechanical arm 201 is set on the top of the inspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com