Conveying pipeline detection device

A technology for conveying pipelines and detection devices, applied in measurement devices, by detecting the appearance of fluid at the leak point, and using liquid/vacuum for liquid tightness measurement, etc. problems, to achieve the effect of reducing the number of uses, quick installation and disassembly, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

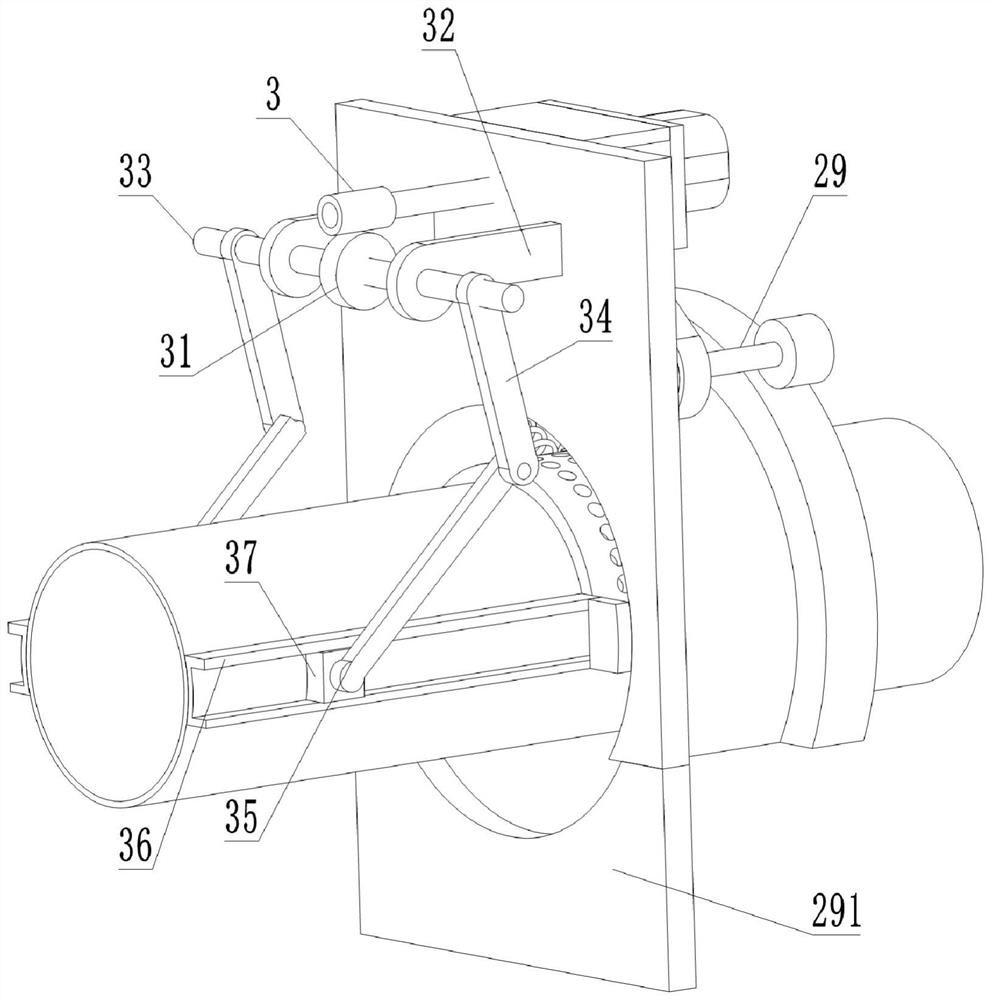

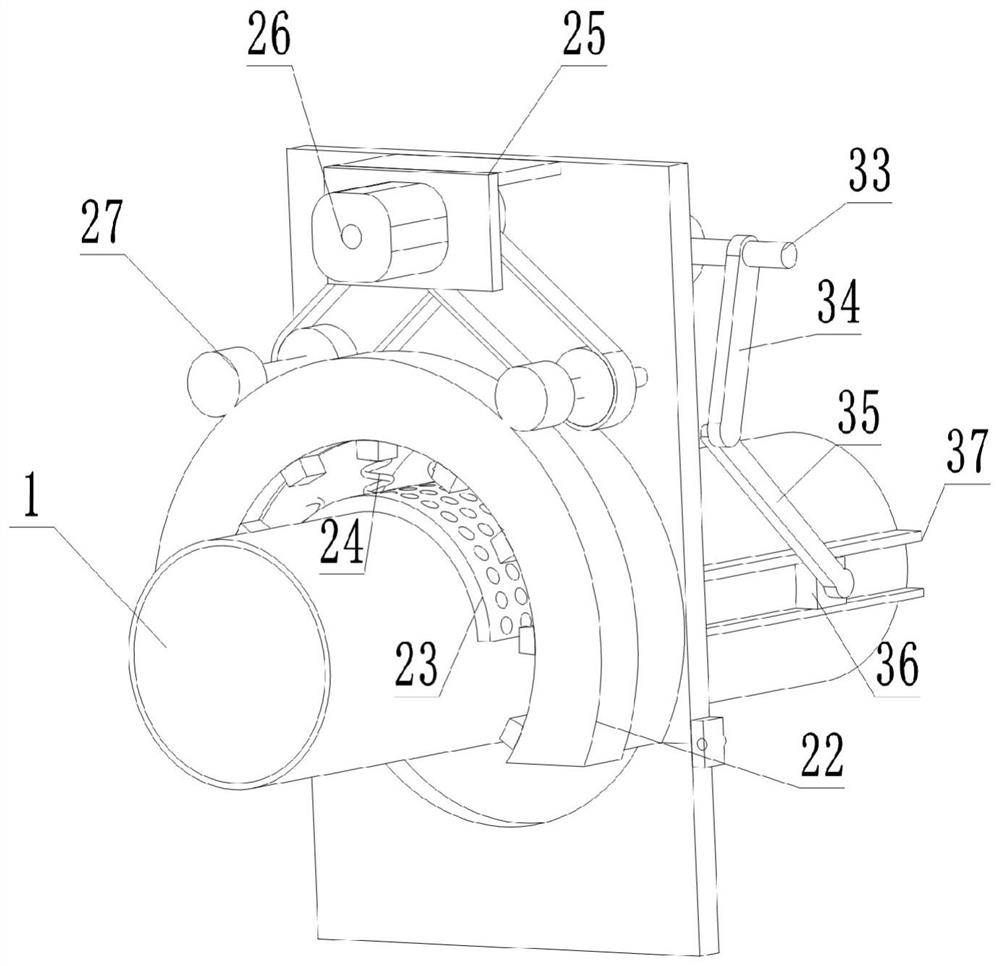

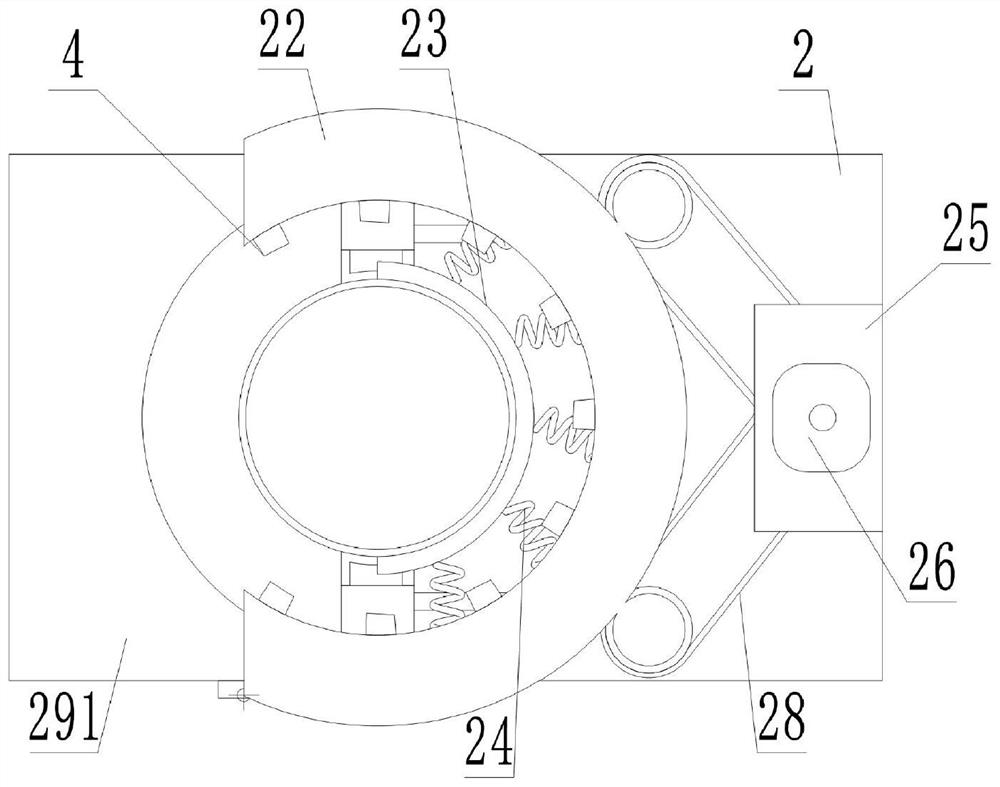

[0028] Such as figure 1 As shown, a detection device for a delivery pipeline 1 is mainly arranged on the delivery pipeline 1 to detect the working condition of the delivery pipeline 1 and whether there is a defect, mainly including the delivery pipeline 1. In this embodiment, the device is used for the delivery The material of the pipeline 1 has certain requirements. The conveying pipeline 1 should be made of a material that can be absorbed by a magnet. Both sides of the width direction of the mounting plate 2 are provided with a detection mechanism and a moving mechanism, wherein the detection mechanism includes a first driving mechanism and a rotating mechanism, and is respectively fixed on both sides of the surface of the mounting plate 2, and the moving mechanism includes a second rotating mechanism and a transmission mechanism. mechanism, the second driving mechanism is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com