Bridge hanging basket construction potential safety hazard monitoring system and control method

A technology of hidden danger and monitoring system, applied in the direction of program control, signal transmission system, electrical program control, etc., can solve the problems of high risk factor of manual operation, difficult to accurately grasp the positioning of hanging basket equipment, and high degree of danger, so as to realize the hidden danger of safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, a specific embodiment of the present invention will be described in detail in conjunction with the accompanying drawings.

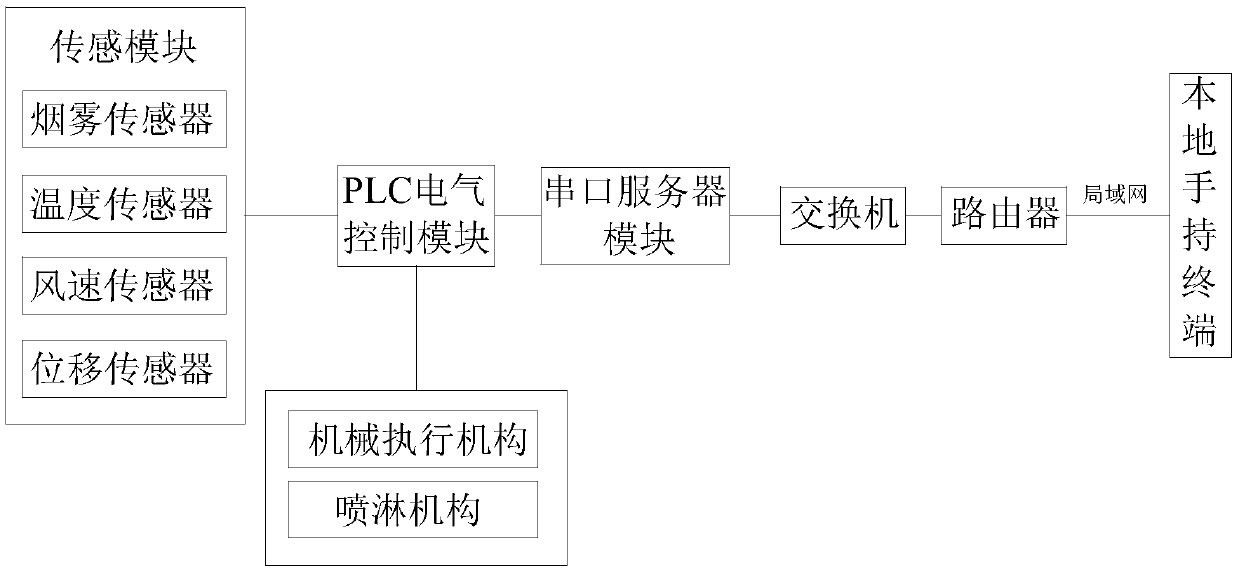

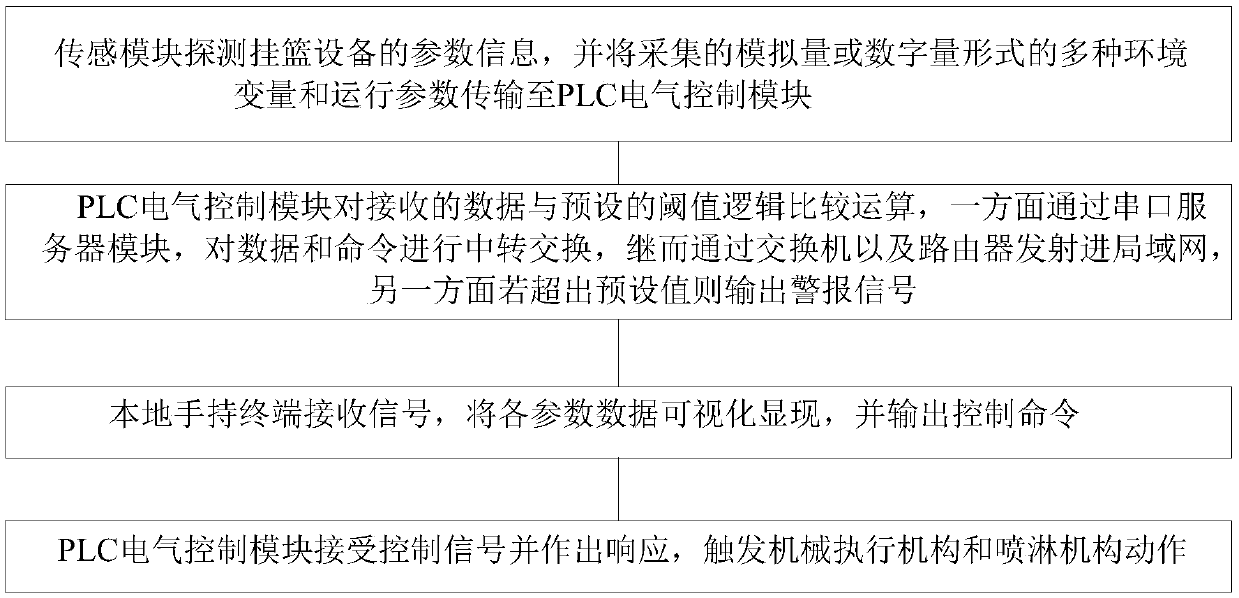

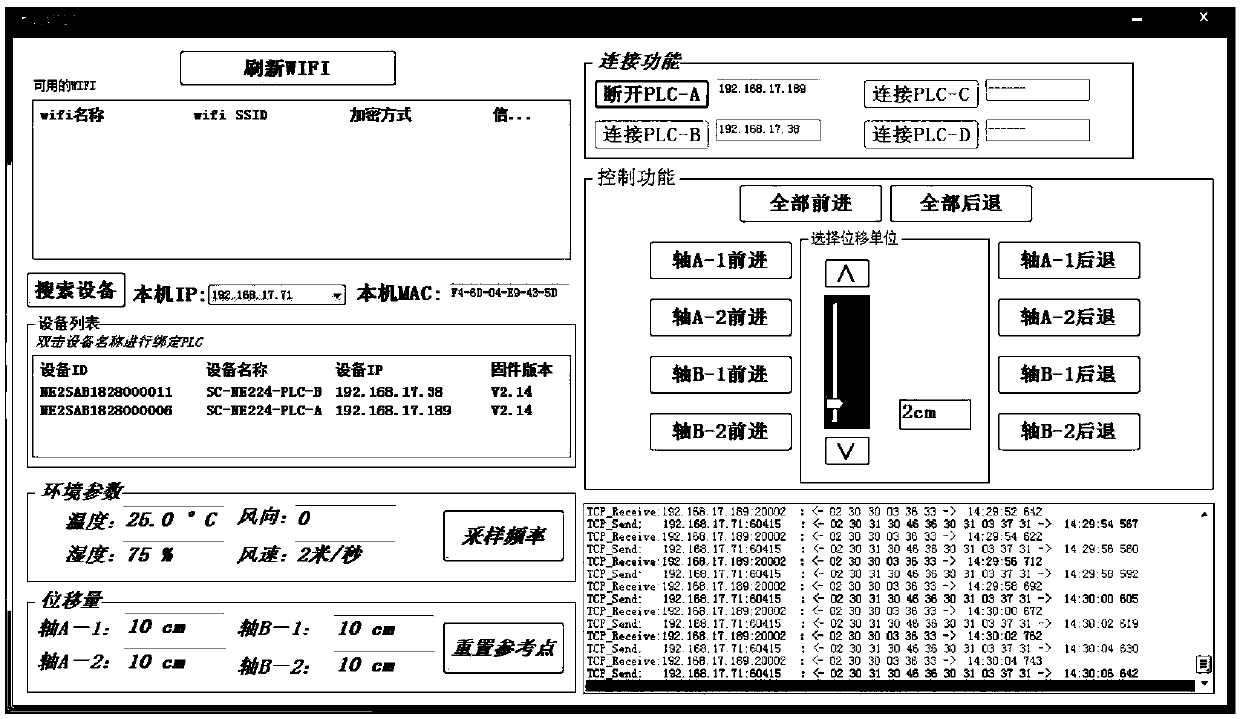

[0020] A bridge hanging basket construction safety hazard monitoring system, comprising a sensing module, an action module, a PLC electrical control module, a serial port server module, a switch, a router and a local handheld terminal; the sensing module, the action module are electrically connected to the PLC electrical control module, The PLC electrical control module is also connected to the remote serial port module, the serial port server module is connected to the switch, the switch is connected to the router, and the local handheld terminal is connected to the router in the local area network formed by the router.

[0021] The sensing module includes a temperature sensor, a wind speed sensor, a smoke sensor and a displacement encoder, and a sensing module is provided on both sides of the hanging basket device to respectively detect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com