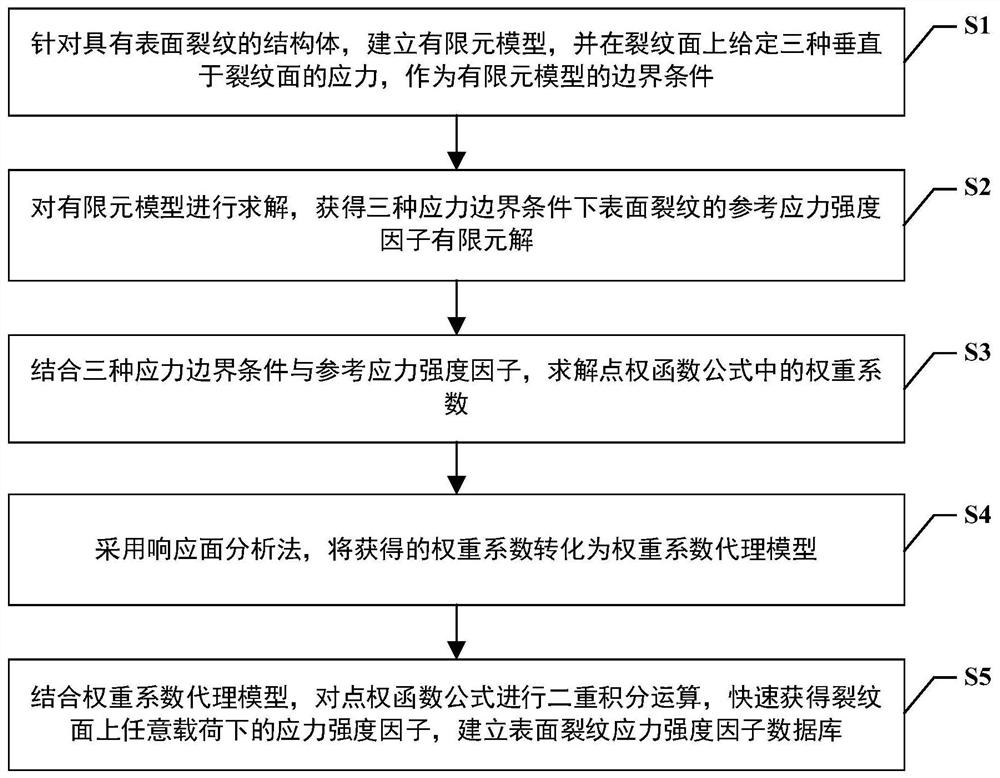

A Method of Establishing Surface Crack Intensity Factor Database Based on Point Weight Function Method

A technology for surface cracking and establishing methods, applied in special data processing applications, design optimization/simulation, calculations, etc., to achieve the effect of making up for limitations and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

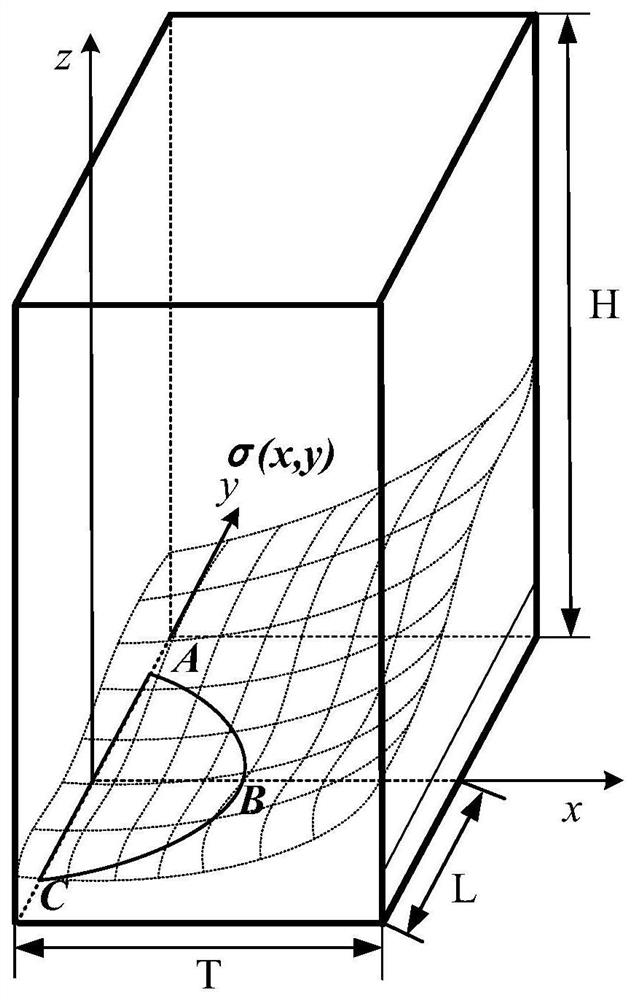

Method used

Image

Examples

Embodiment 1

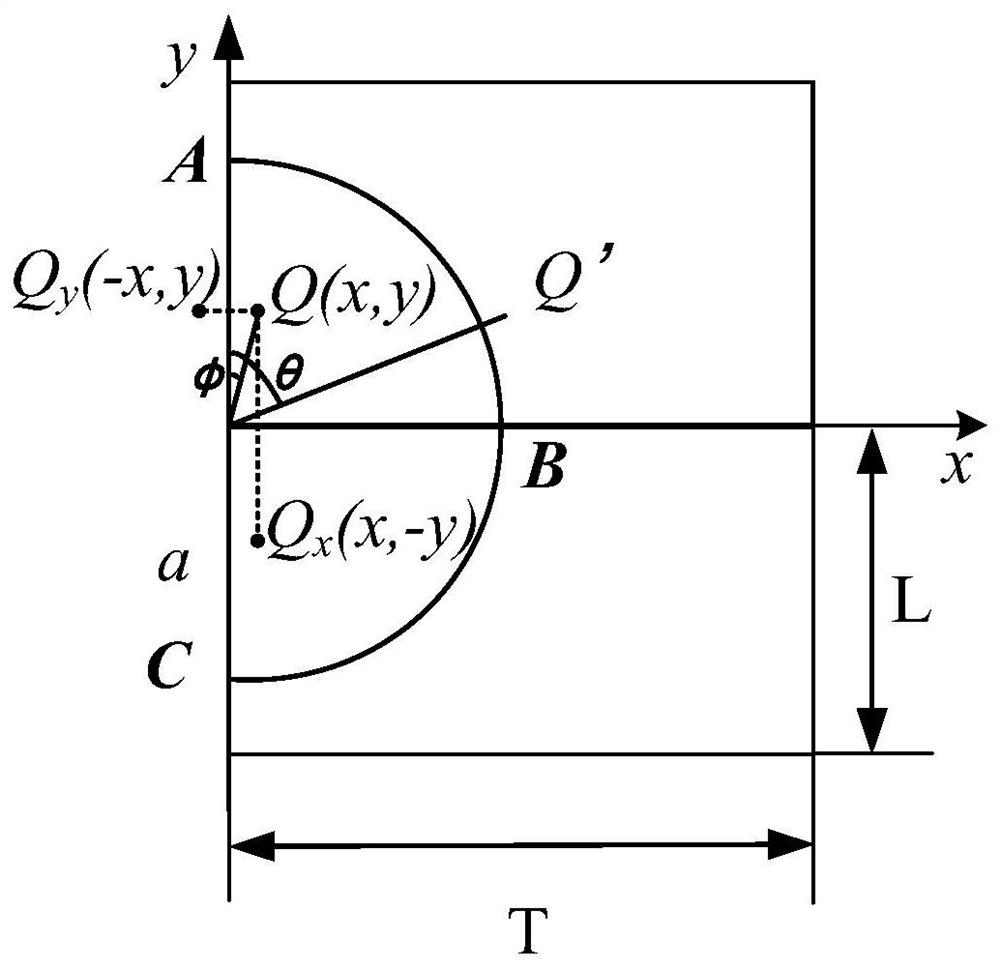

[0120] Different stress gradients are given to the semicircular cracks on the surface, such as Figure 5 Shown, where, (a) is the stress σ v1 The stress distribution on the crack surface when , (b) is the stress σ v2 The stress distribution on the crack surface when

[0121]

[0122]

[0123] Among them, σ v1 and σ v2 is the stress distribution on the crack surface, with the center of the semicircular crack as the origin, the thickness direction of the structure is the X axis, the width direction of the structure is the Y axis, and x and y are the abscissa and ordinate values of any point on the crack surface, respectively.

[0124] According to the method of the present invention, the stress intensity factors of surface cracks at different radii a and different structure widths and thicknesses L, T can be obtained. In addition, according to the finite element modeling method, precise values of stress intensity factors can be obtained, such as Figure 6 (a) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com