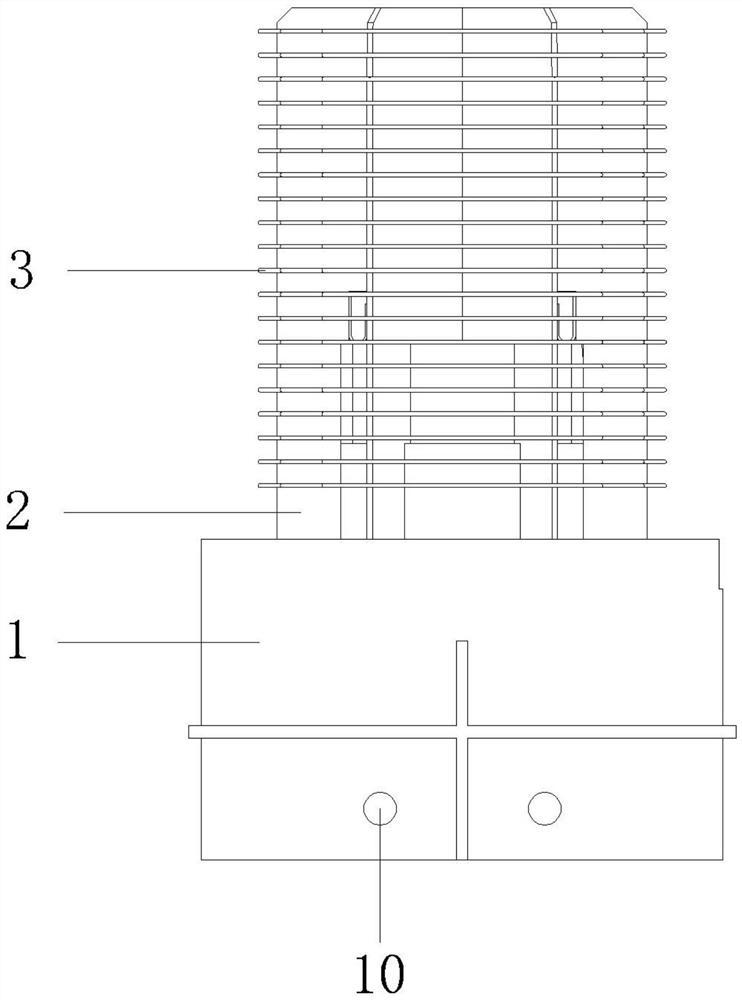

Novel electric heating structure of hair drier

A hair dryer and electric heating technology, applied in clothing, contact parts, hairdressing equipment, etc., can solve the problems of complex operation, large accumulation, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

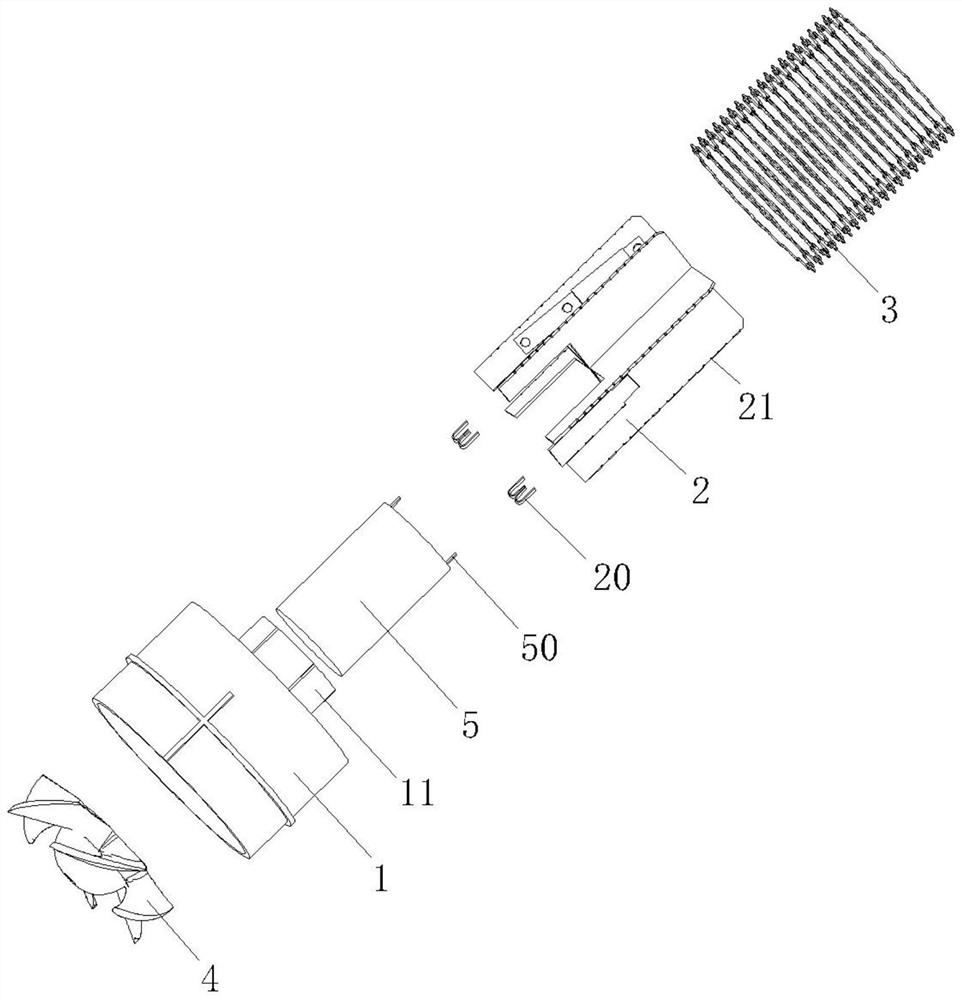

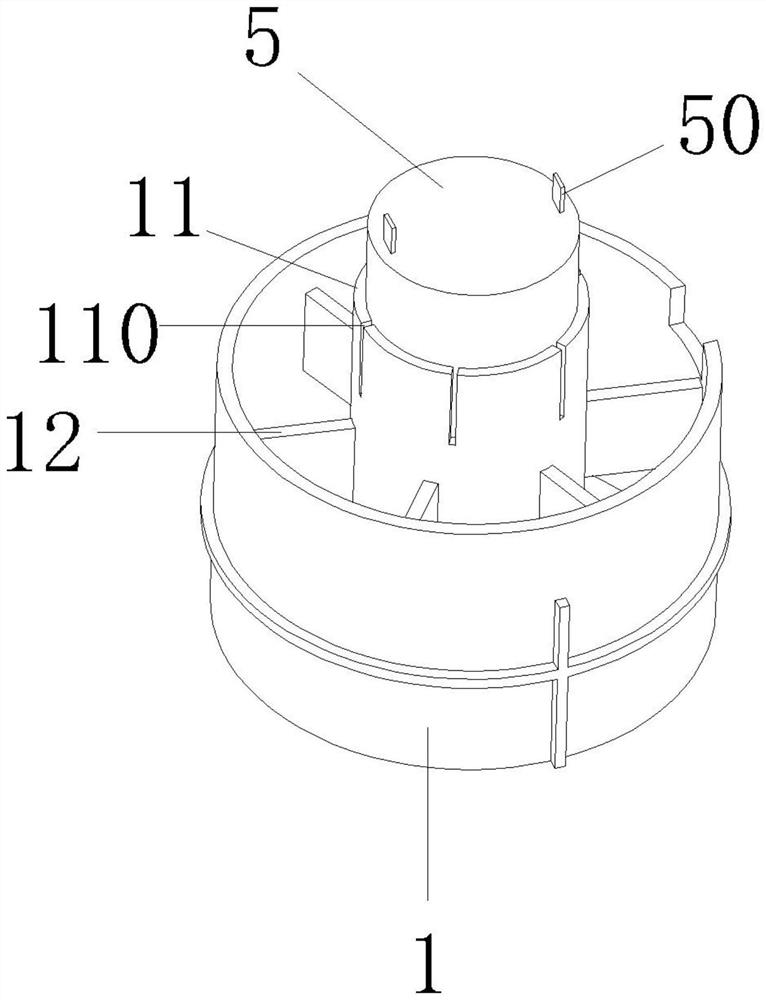

[0033] As an improved specific embodiment, the conductive plate 2 includes a first plate body 22 and a second plate body 23, the upper end of the first plate body 22 is provided with a first socket 220, and the lower end of the second plate body 23 is A second socket 230 is provided, and the first socket 220 and the second socket 230 can be plugged and interfered with each other.

[0034] Through the plug-in structure of the first plate body 22 and the second plate body 23, the detachable structure of the conductive plate 2 is realized, which is more convenient in terms of cleaning, replacement and transportation, and the connection is very firm.

[0035] As an improved specific embodiment, the front section of the first socket 220 and the second socket 230 is provided with a fixed sleeve 24, the fixed sleeve 24 is in the shape of a cross, and the first plate body 22 and the second plate body 23 are inserted After connection, the fixing sleeve 24 can be sleeved on the front se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com