A kind of electrical embedded pipe protection device and construction method thereof

A technology for electrical pre-embedded pipes and protective devices, which is applied in the direction of cable installation devices, electrical components, and cable installations, and can solve the problems of poor fixing effect, weak protection, and poor practicability of electrical pre-embedded pipes, and achieve practical Sexual protection, reduce the effect of bonding, and ensure the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

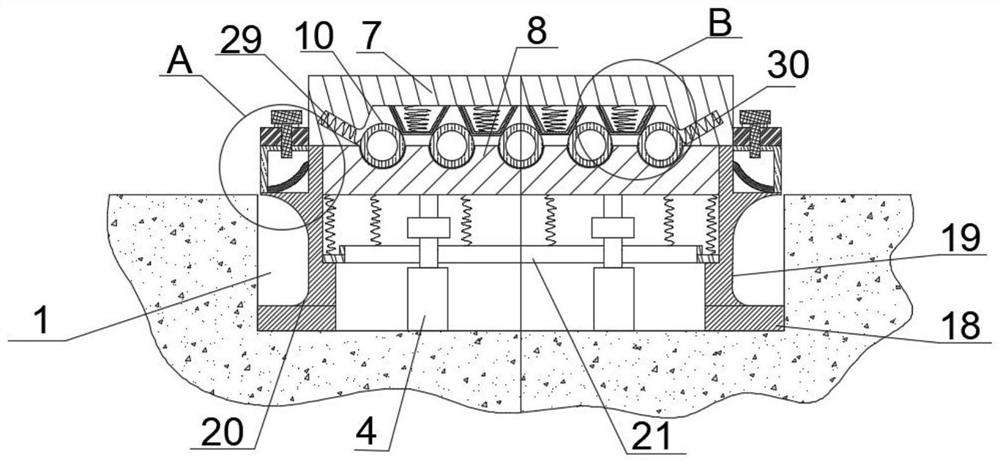

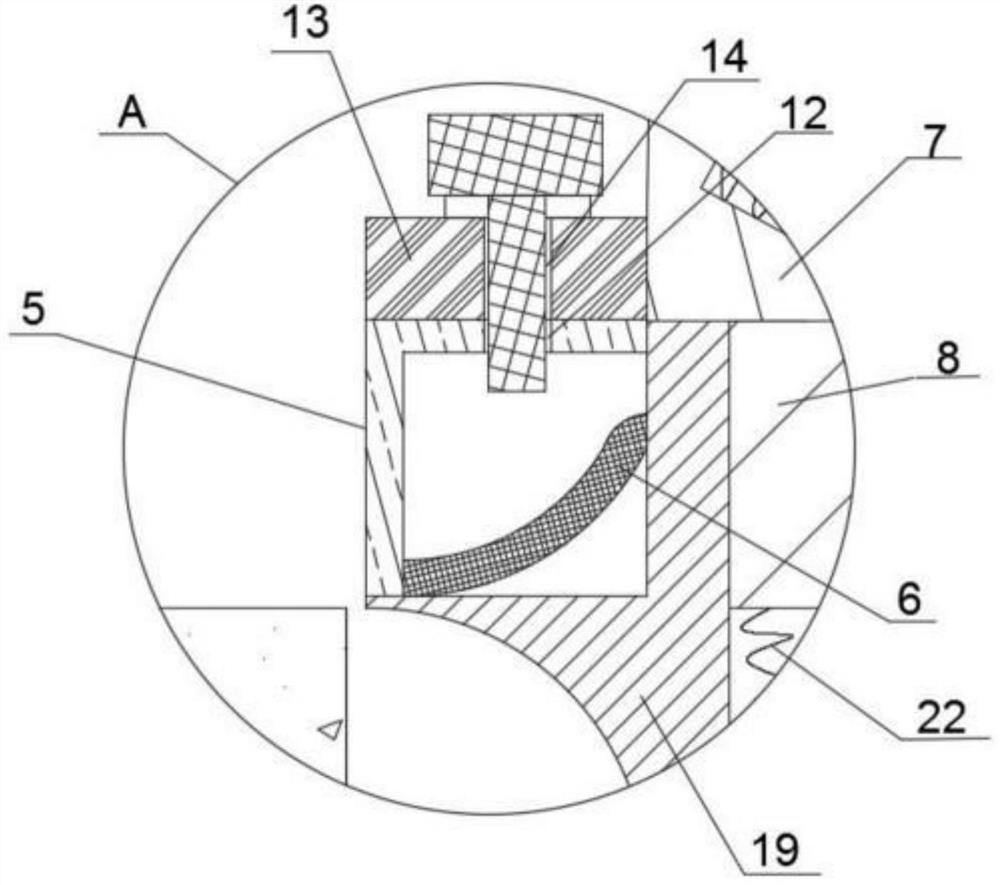

[0052] like Figure 1 to Figure 5 As shown, it is an embodiment of the present invention, an electrical pre-buried pipe protection device, including a support and a positioning pipe frame, the support is located on the lower side of the positioning pipe frame, and the support is suitable for being installed in the embedded groove 1, An embedded part 2 is installed in the embedded groove 1, and the upper end of the embedded part 2 is provided with an external thread;

[0053] The support includes a support frame 3 and a locking sleeve 4, the support frame 3 is connected with the positioning pipe frame, the support frame 3 is fitted with the embedded groove 1, the locking sleeve 4 is provided with internal threads, and the locking sleeve 4 is connected with the embedded groove 1. Piece 2 threaded connection;

[0054] The support frame 3 includes an anti-seepage part, the anti-seepage part is located at the upper end of the support frame 3, the anti-seepage part is integrally co...

Embodiment 2

[0061] like Image 6 and Figure 7 As shown, it is another embodiment of the present invention. On the basis of Example 1, it is added: the horizontal portion 18 is provided with a mounting hole 23, the mounting hole 23 is vertically arranged on the horizontal portion 18, and the mounting hole 23 is installed in the mounting hole 23. There are fixing feet 24, the fixing feet 24 are inverted "T" shape along the working horizontal section, the fixing feet 24 are provided with a first positioning hole 25, and the side of the horizontal portion 18 away from the annular plate 21 is provided with a second positioning hole 26, The first positioning hole 25 corresponds to the second positioning hole 26 , and the horizontal portion 18 and the fixing foot 24 are adapted to be threadedly connected by bolts.

[0062] The first arc grooves 9 are provided with multiple groups, and the multiple groups of the first arc grooves 9 are arranged in parallel and horizontally;

[0063] The buffer...

Embodiment 3

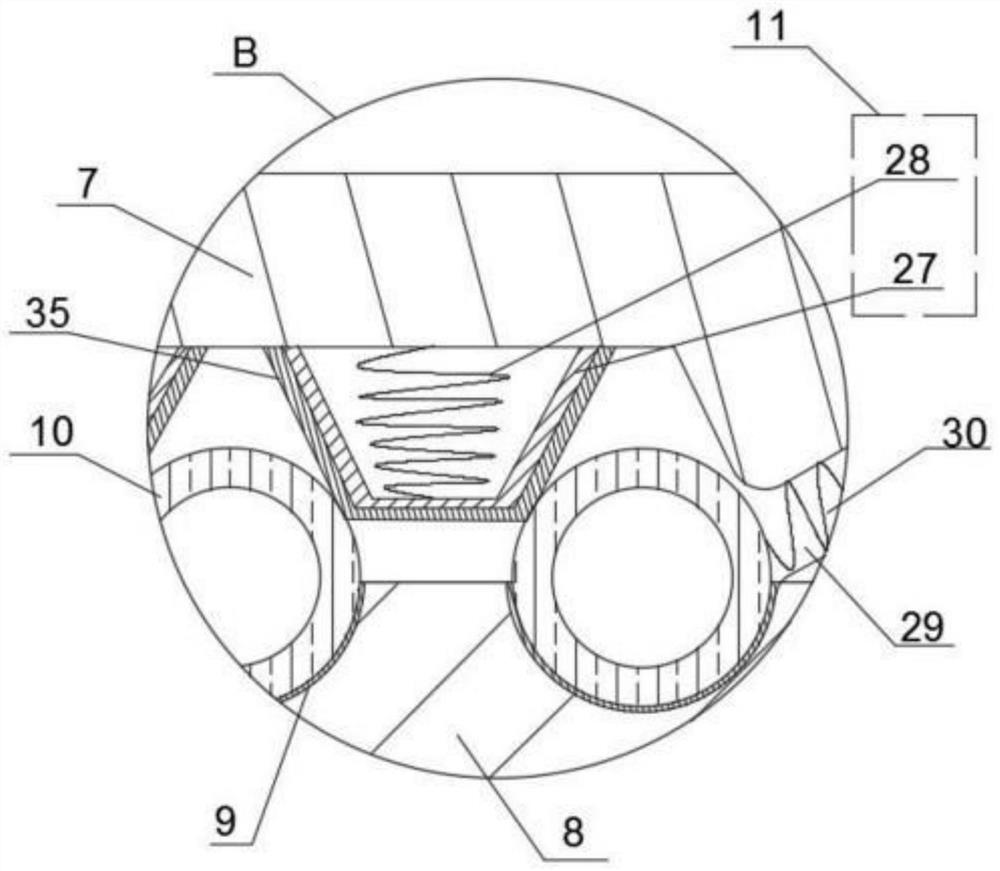

[0066] like Figure 8 and Figure 9 As shown, it is another embodiment of the present invention. On the basis of Example 2, it is added: the lower casing 8 is provided with a connecting column 31, the connecting column 31 is located between the first arc grooves 9, and the connecting column 31 A combination plate 32 is installed on the upper part, a groove 33 is arranged under the combination plate 32, the groove 33 is clamped with the connecting column 31, the combination plate 32 is provided with a second arc groove 34, and the second arc groove 34 is suitable for fitting Electrical embedded pipe 10;

[0067] The first circular arc groove 9 and the second circular arc groove 34 are provided with a rubber layer 35 , a rubber layer 35 is provided under the fixing feet 24 , and a rubber layer 35 is provided on the surface of the extrusion plate 27 .

[0068] A construction method for an electrical embedded pipe protection device, characterized in that it comprises the followi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap