Waste spring stretching and recycling machine

A technology of side plates and transmission wheels, applied in the manufacture of springs from wires, applications, household appliances, etc., can solve the problems of manpower consumption, cumbersome operation process, and low work efficiency, and achieve the goal of improving work efficiency, simple operation, and saving manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

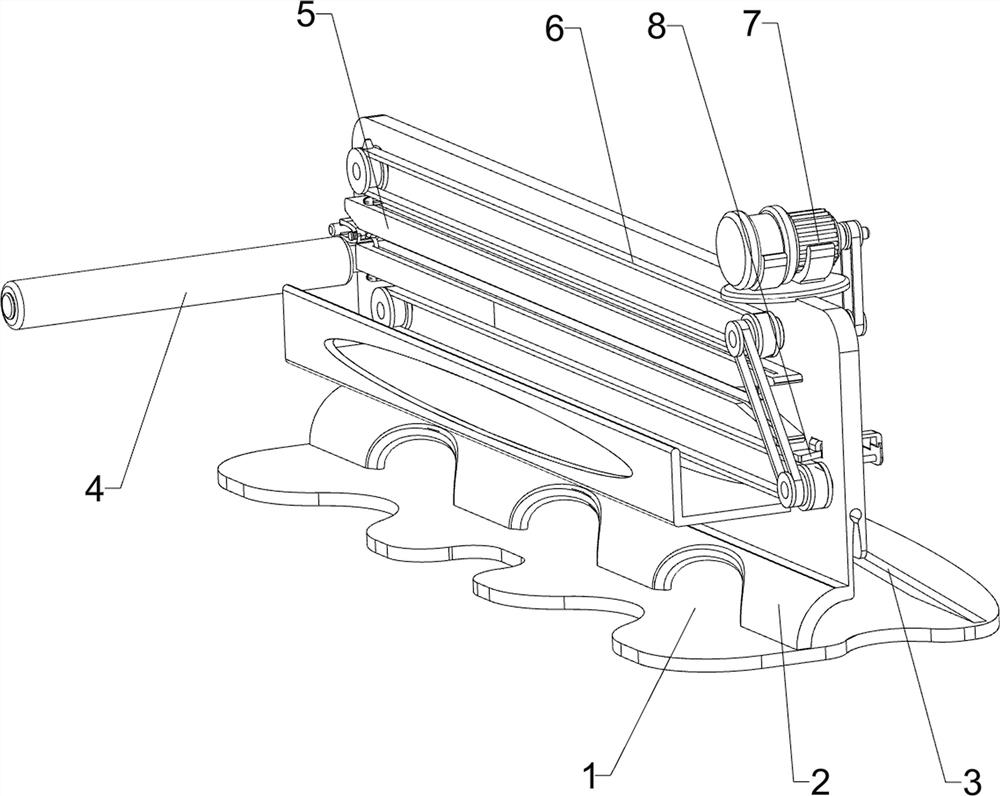

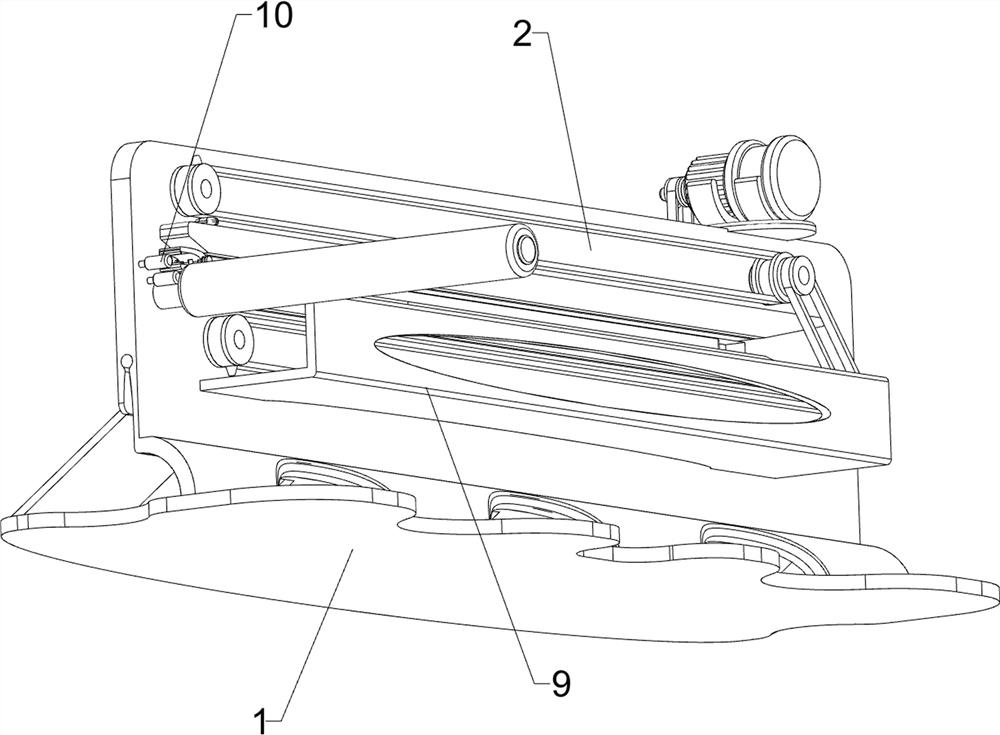

[0026] A waste spring stretching reuse machine, such as Figure 1 to Figure 3 As shown, it includes a mounting plate 1, a side plate 2, a support plate 3 and a roller 4. The top of the mounting plate 1 is connected to the side plate 2, and the support plate 3 is connected between the side plate 2 and the mounting plate 1. The left side of the side plate 2 The side and rear sides are rotatably connected with a roller 4, and also include a clamping device 5, a transmission device 6 and a transmission device 7. The side plate 2 is provided with a clamping device 5, a transmission device 6 and a transmission device 7, and the transmission device 6 It is connected with transmission device 7.

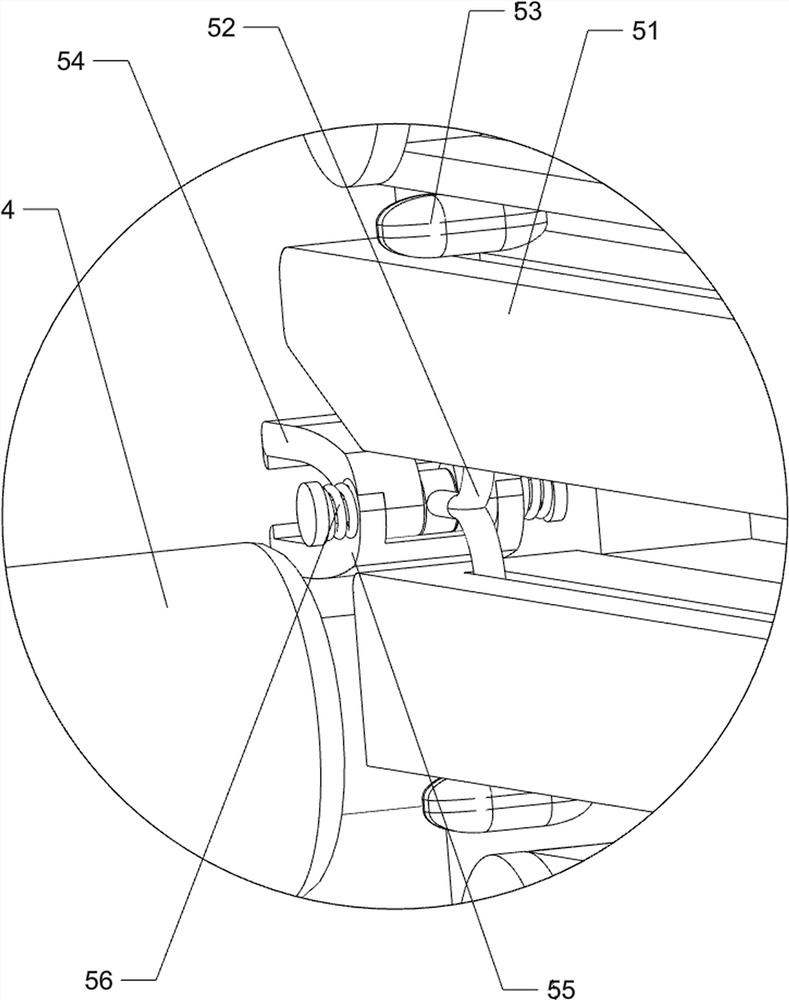

[0027] The clamping device 5 includes a guide plate 51, a connecting rod 52, a slide block 53, an upper clamping plate 54, a lower clamping plate 55 and a torsion spring 56. The left side of the side plate 2 is connected with a guide plate 51 on the upper and lower sides. The connecting rod ...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 4 Shown, also include pushing device 8, and pushing device 8 includes slide bar 81, connecting sleeve plate 82, return spring 83, push plate 84, L-shaped bar 85, cross plate 86, wedge block 87 and guide rod 88, side Both front and rear sides of the right side of the plate 2 are connected with slide bars 81, and a connecting cover plate 82 is slidably connected between the two slide bars 81, and a return spring 83 is connected between the connecting cover plate 82 and the side plate 2, and the connecting cover plate The front and rear sides of the top of 82 are connected with L-shaped rods 85, and a push plate 84 is connected between the L-shaped rods 85 on both sides. Guide rod 88 is slidably matched with connection cover plate 82, and the front side of connection cover plate 82 is connected with cross plate 86, and cross plate 86 is slidably matched with side plate 2, and the left side of cross plate 86 is connected with wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com