Damping structure of hydropower station generator layer plate beam

A technology for generators and slab girders of hydropower stations, which is applied in hydropower, hydropower stations, and earthquake prevention, can solve problems such as floor vibration and column fatigue damage, reduce impact, facilitate use, and reduce the risk of column fatigue damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-5 The application is described in further detail.

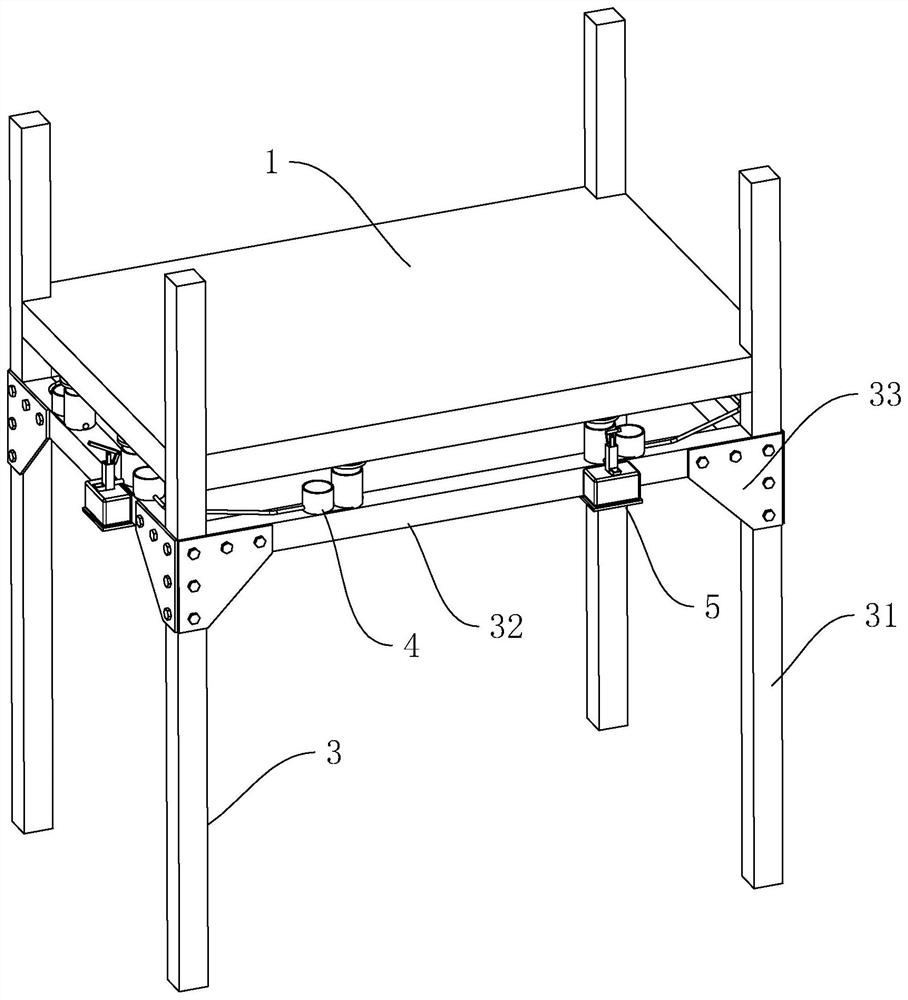

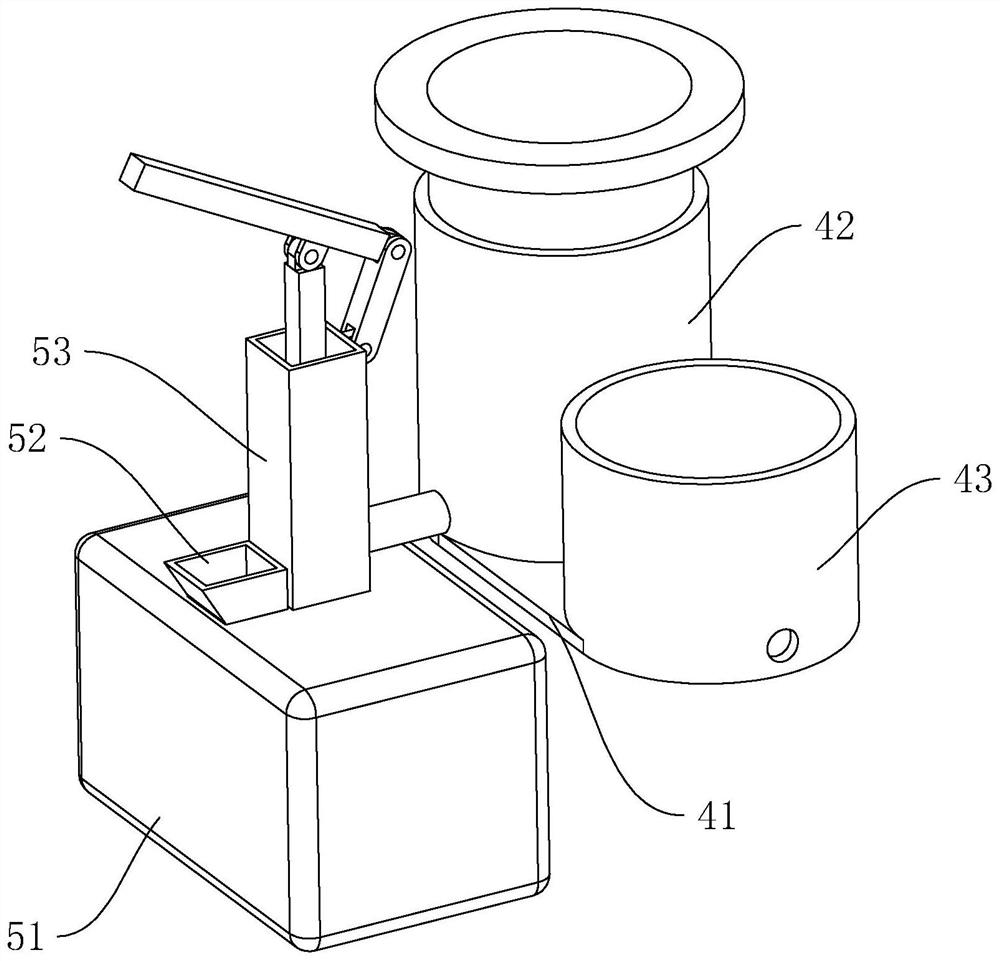

[0034] The embodiment of the present application discloses a damping structure for the deck beam of a hydroelectric power station generator. figure 1 , including a prefabricated floor 1 and a frame assembly 3 for supporting the prefabricated floor 1 , the prefabricated floor 1 is used for installing a hydroelectric generator set, and a shock absorbing assembly 4 is arranged between the prefabricated floor 1 and the frame assembly 3 .

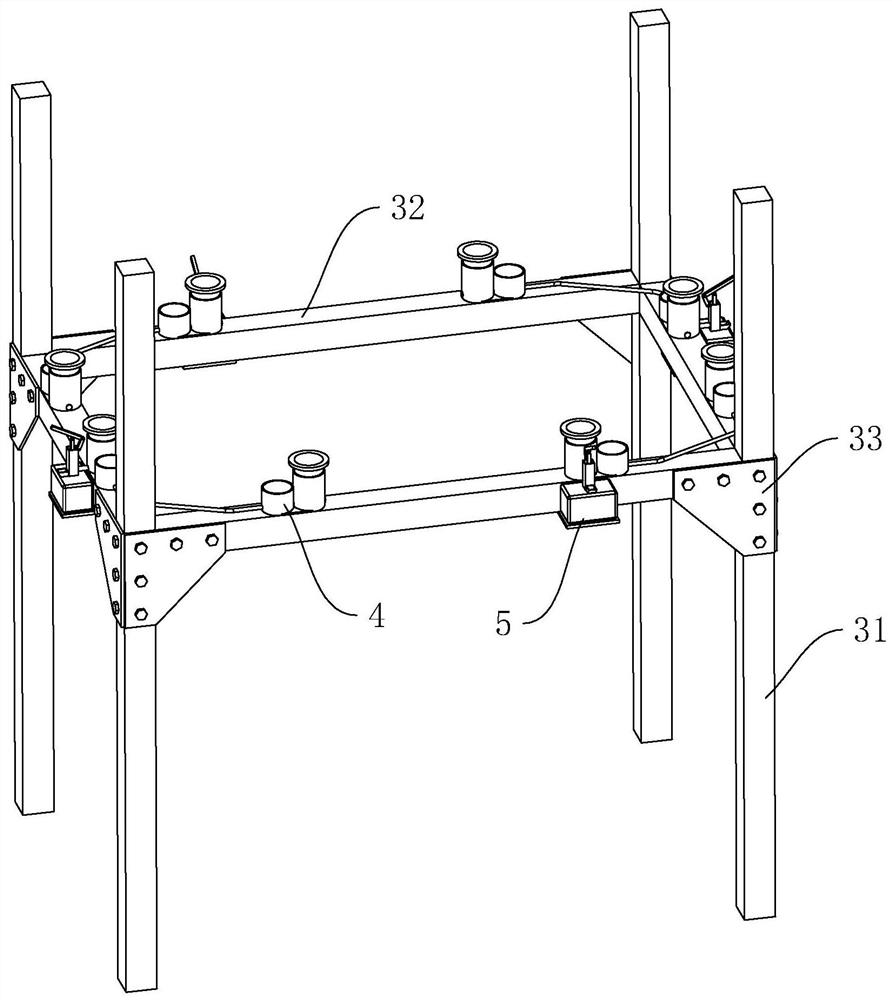

[0035] refer to figure 1 and figure 2 , the frame assembly 3 includes at least three uprights 31, which can be three, four or more, preferably four in this embodiment, the uprights 31 are vertically fixed on the ground, and adjacent uprights 31 are fixed with The crossbeams 32, four groups of crossbeams 32 are at the same height, forming a rectangle. A support plate 33 is provided at the joint between the beam 32 and the column 31 , the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com