Speed change mechanism for achieving automatic gear shifting through output speed and vehicle

A technology of automatic gear shifting and transmission mechanism, which is applied in the direction of automatic clutch, mechanical equipment, transmission device, etc. It can solve problems affecting riding experience, transmission mechanism failure, and affecting service life, so as to improve riding experience, ensure reset, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

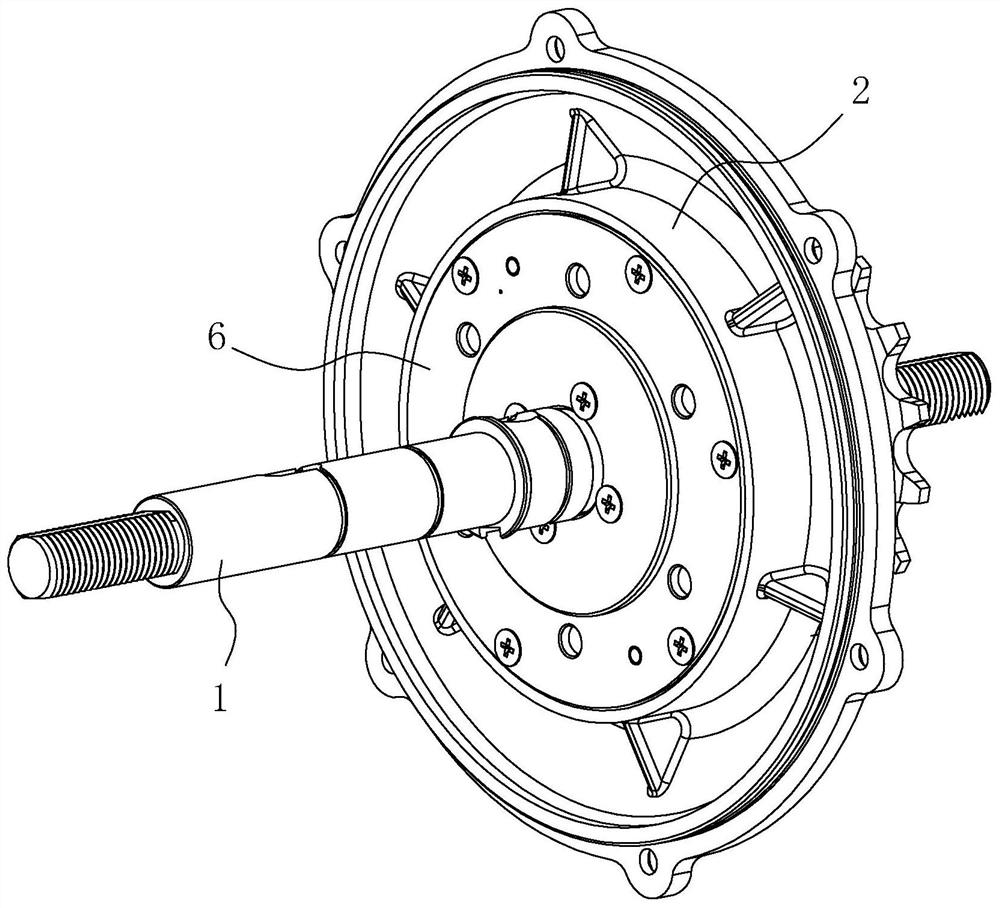

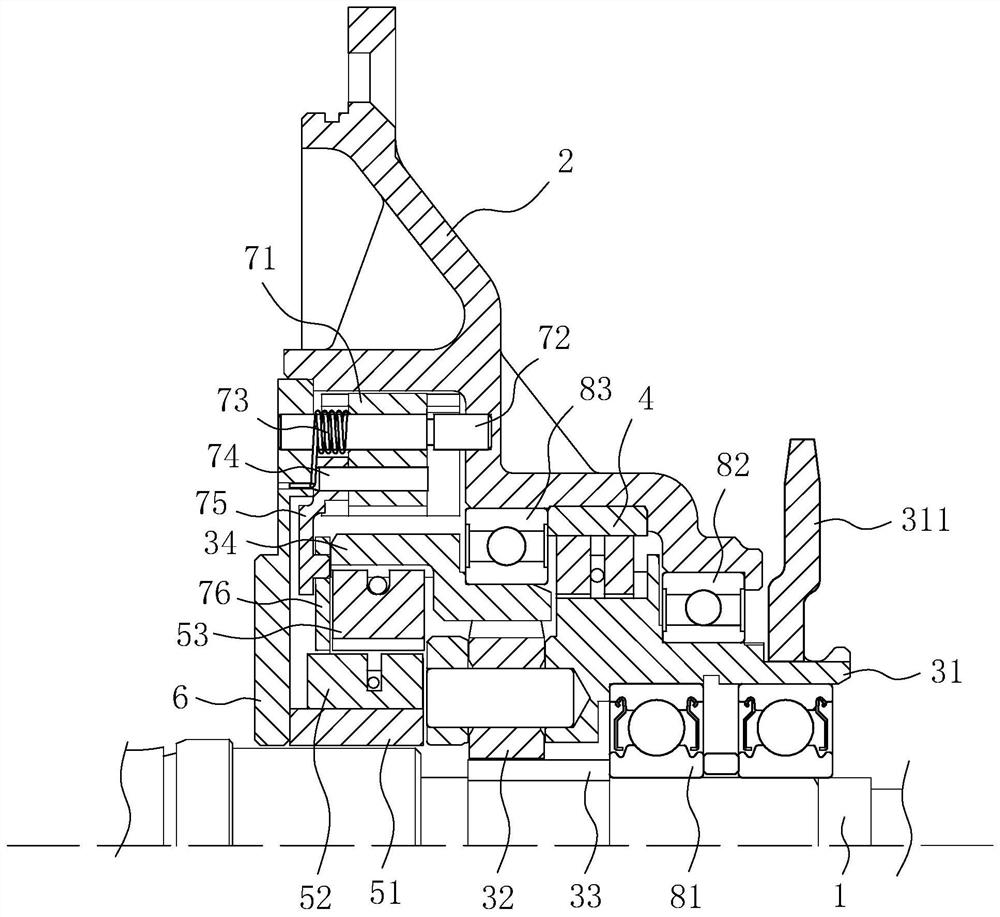

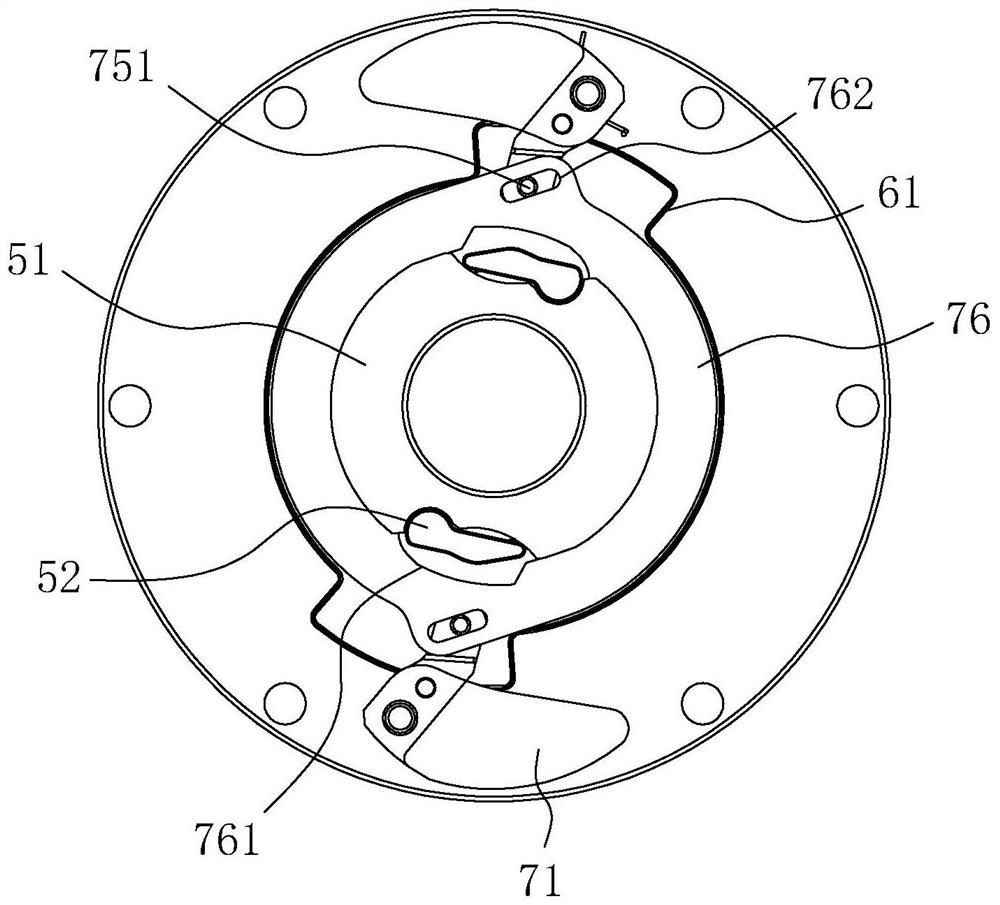

[0037] A speed change mechanism that uses output speed to realize automatic shifting, refer to figure 1 and figure 2 , which includes a power output unit and a power output unit; the power input unit includes a first input member and a second input member, and the rotation speed of the second input member is higher than that of the first input member; between the first input member and the power output unit A first clutch assembly is provided, a second clutch assembly is provided between the second input member and the power output unit, and the power output unit is provided with a centrifugal drive assembly for controlling the second clutch assembly; wherein, the speed of the power output unit is lower than When the value is set, the centrifugal drive assembly restricts the second clutch assembly, so that the speed of the second input cannot be transmitted to the power output unit through the second clutch assembly. At this time, the speed of the first input is transmitted t...

Embodiment 2

[0051] A vehicle including the transmission mechanism in Embodiment 1.

[0052] The vehicle in this embodiment may be a bicycle, an electric power-assisted bicycle or other vehicles that need to change speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com