Thermal insulation material, refrigerator, and manufacturing method of heat insulation material

A heat insulation material and manufacturing method technology, which is applied in the direction of household refrigeration equipment, refrigeration equipment isolation, lighting and heating equipment, etc., can solve the problems of thinning, reduced air tightness of outsourcing parts, and reduced heat insulation of heat insulation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

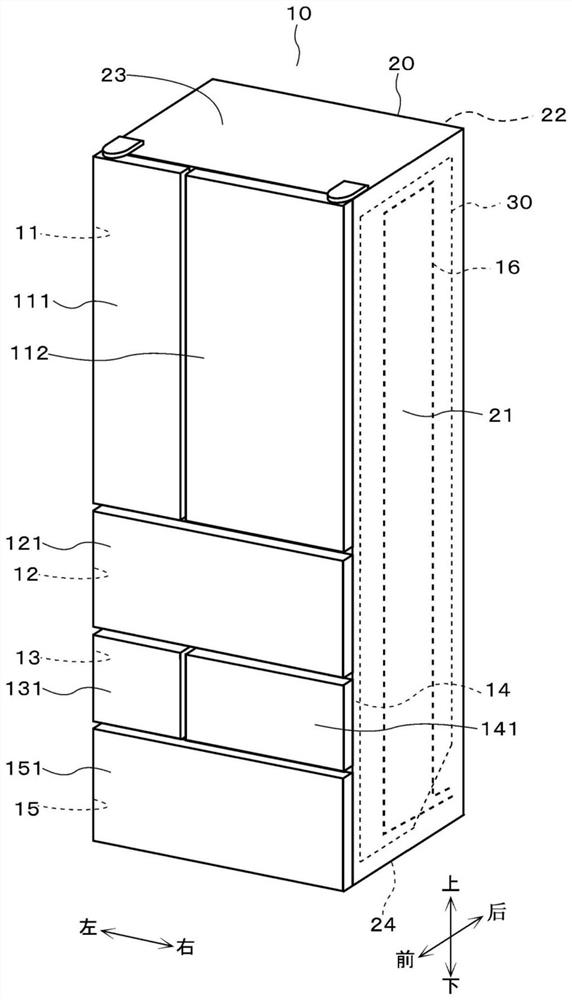

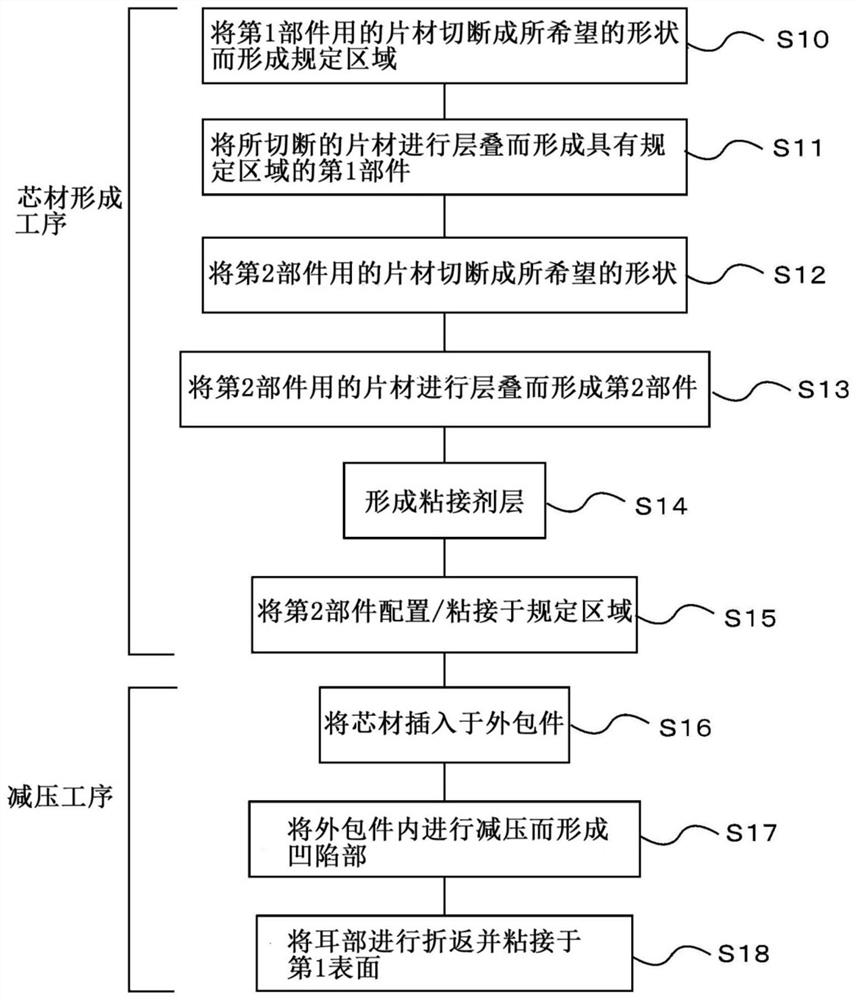

[0031] First, refer to Figure 1 to Figure 5 , and the first embodiment will be described. Such as figure 1 As shown, the refrigerator 10 is configured by having a plurality of storage chambers in a longitudinally long rectangular heat-insulating box 20 with an open front surface. In the following description, the opening side of the refrigerator 10 is referred to as the front side of the refrigerator 10 , and the side opposite to the opening is referred to as the rear side of the refrigerator 10 . In addition, after setting the refrigerator 10 to figure 1 When the refrigerator 10 is installed on the ground, the up-down direction corresponding to the direction of gravity is defined as the up-down direction of the refrigerator 10 . In addition, when viewed from the front side figure 1 In the case of the refrigerator 10, let the left-right direction be the left-right direction of the refrigerator 10. In addition, regarding the refrigerator 10, the inside of each storage roo...

no. 2 Embodiment approach

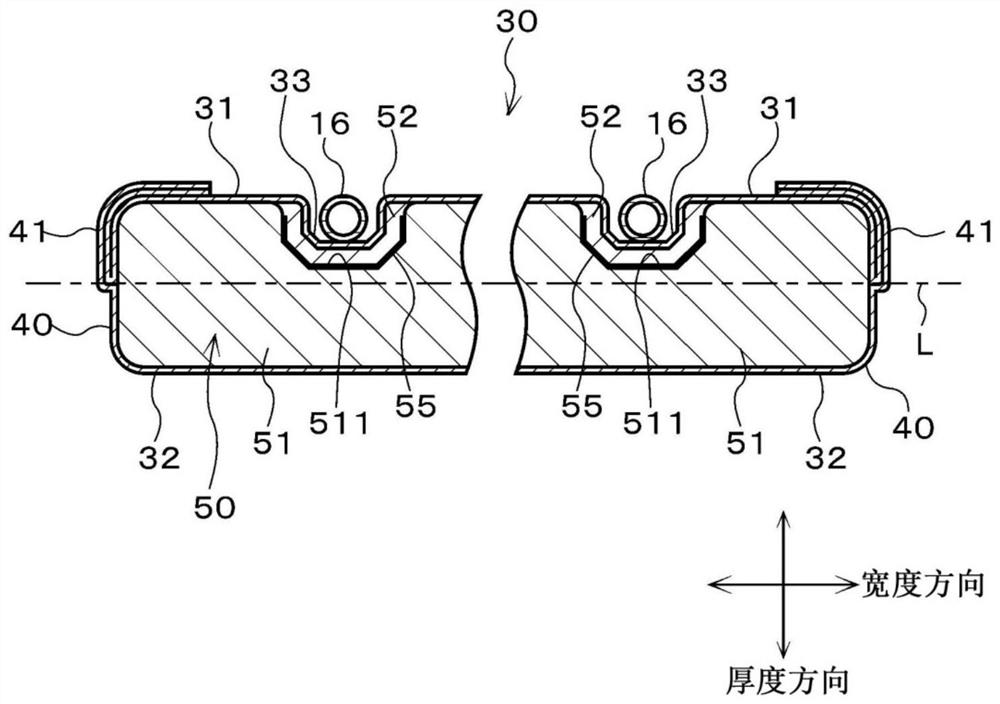

[0083] Next, refer to Figure 6 ~ Figure 8 , and the second embodiment will be described. In this embodiment, the vacuum insulation panel 30 further includes the third member 53 . The third member 53 is formed in a plate shape, and is composed of another member different from the first member 51 and the second member 52 . The third member 53 is provided on the first surface 31 side of the first member 51 and is in contact with the peripheral portion 512 which is a portion adjacent to the recessed portion 33 . In this case, the third member 53 is arranged to constitute a plane parallel to the first surface 31 and the second surface 32 . The third member 53 and the peripheral portion 512 may be bonded together with an unillustrated adhesive.

[0084] The third member 53 is configured to have lower compressibility than the first member 51 and the second member 52 . In other words, the third member 53 is configured to be more rigid than the first member 51 and the second membe...

no. 3 Embodiment approach

[0091] Next, refer to Figure 9 , and the third embodiment will be described. Such as Figure 9 As shown, the outer cover 40 has a first portion 401 and a second portion 402 . The first portion 401 is provided in a portion of the outer cover 40 covering at least a part of the peripheral portion 512 of the first member 51 . The second portion 402 is provided in a portion of the outer case 40 that covers the second member 52 .

[0092] The rigidity of the first part 401 is higher than that of the second part 402 . In the present embodiment, for example, the first portion 401 is configured to increase the rigidity by increasing the thickness of the cover material 40 to be thicker than the thickness of the second portion 402 . That is, it is configured such that a resin film is attached to a portion corresponding to the first portion 401 of the outer cover 40 from the outside. In addition, the first part 401 can be configured to increase the rigidity by increasing the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com