Method for testing fluidity gradual loss of grouting slurry stratified flow cone

A test method and fluidity technology, applied in the measurement of DC flow characteristics, etc., can solve the problems of inapplicability and the deviation of test results from the actual situation, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

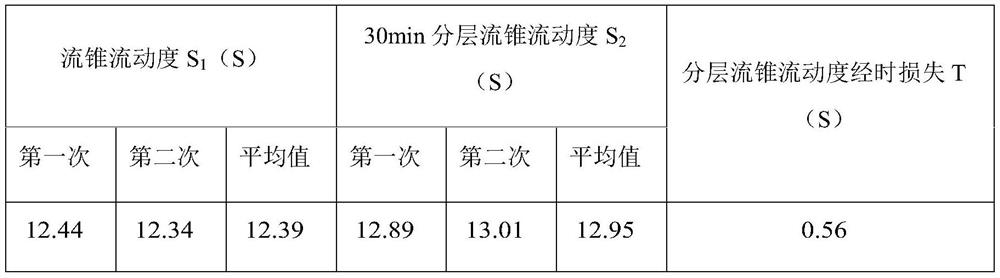

[0062] Mix the grout according to the synchronous grouting slurry mix ratio shown in Table 1, and use the flow cone fluidity tester to detect the flow cone fluidity S of the grouting slurry in the initial state 1 , and then put the slurry into the mortar stratification meter, vibrate on the concrete vibrating table for 5s, and then let it stand for 30min. The vibration frequency of the concrete vibrating table is 2860 times / min, and the amplitude is 0.3-0.6mm. The vibrator power of the concrete vibrating table is 0.55kw. 100kg. Pour the 100mm slurry from the lower part of the mortar stratification meter into the container, stir it quickly with a small spoon, then quickly pour it into the flow cone fluidity tester, and measure the fluidity S of the stratified flow cone of the grouting slurry for 30 minutes 2 .

[0063] Calculate the time-lapse loss T of stratified flow cone mobility. Referring to Table 2, the time-lapse loss of stratified flow cone fluidity is 0.56s.

[006...

Embodiment 2

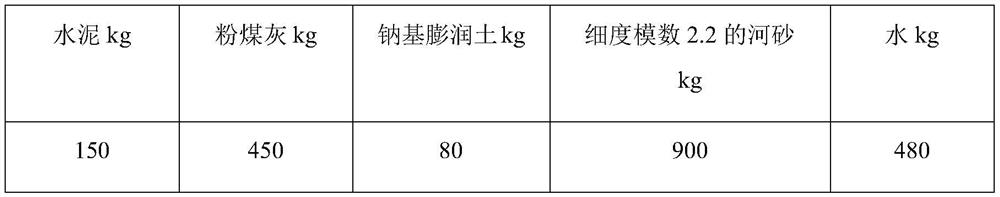

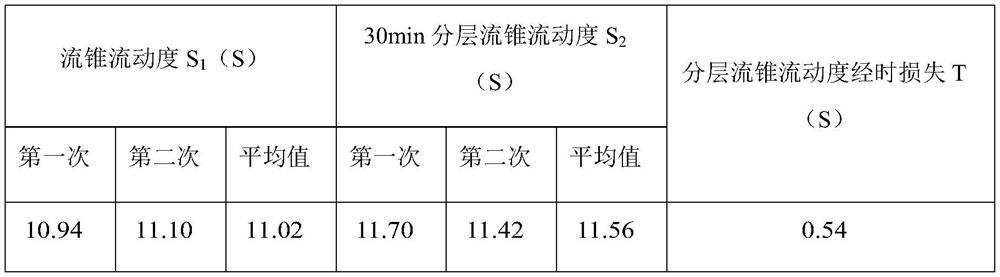

[0069] Mix the slurry according to the synchronous grouting slurry mix ratio shown in Table 3, and use the flow cone fluidity tester to detect the flow cone fluidity S of the grouting slurry in the initial state 1 , and then put the slurry into the mortar stratification meter, vibrate on the concrete vibrating table for 10 seconds, and then let it stand for 30 minutes. The vibration frequency of the concrete vibrating table is 2860 times / min, and the amplitude is 0.3-0.6mm. The vibrator power of the concrete vibrating table is 0.55kw. 100kg. Pour the 100mm slurry from the lower part of the mortar stratification meter into the container, stir it quickly with a small spoon, then quickly pour it into the flow cone fluidity tester, and measure the fluidity S of the stratified flow cone of the grouting slurry for 30 minutes 2 .

[0070] Calculate the time-lapse loss T of stratified flow cone mobility. Referring to Table 4, the loss of stratified flow cone fluidity over time is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com