A method for optimizing the production process of pc solid sheet and its multifunctional coating comprehensive performance detection device

A multi-functional coating, comprehensive performance technology, applied in the field of solid board, can solve the problems of not considering scattering intensity, backward production process, lack of intelligent instruments, etc., to save order completion time, save communication costs, and improve customer experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

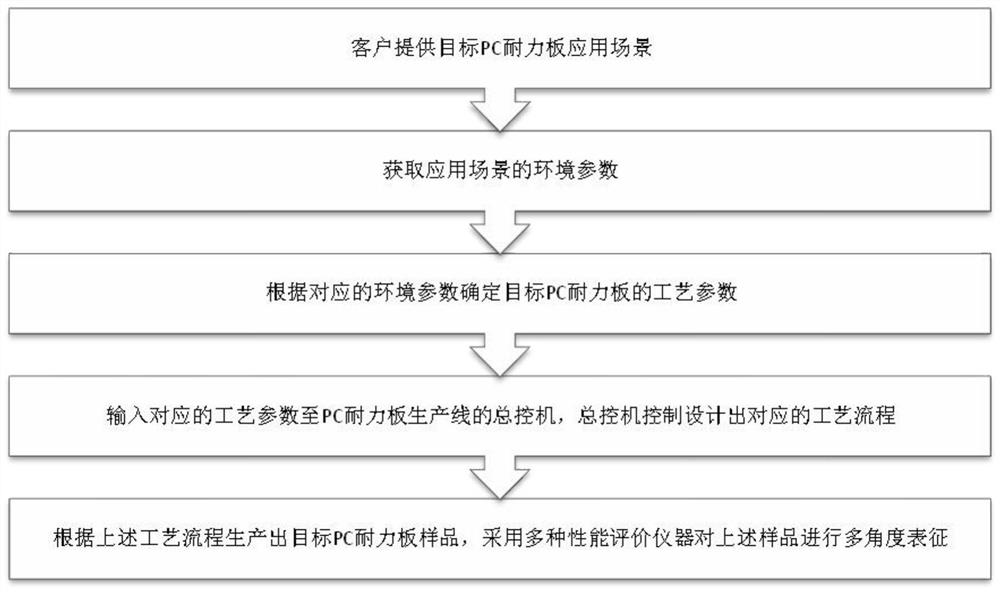

[0060] The user receives an order intention from a certain area near the equator. The target product of the order customer is a PC endurance board for seaside resting pavilions. That is to say, the target application scenario can be determined at this time - the seaside, and the environmental parameters of the application scenario can be determined, including Its UV intensity and PM value, temperature, humidity, and corrosion index. The above-mentioned environmental parameters can be measured on the spot by instruments and equipment, or can be provided by the customer, can also be generated from the historical data of the local meteorological station, or provide the environmental parameters of the same or similar environment through the historical order data.

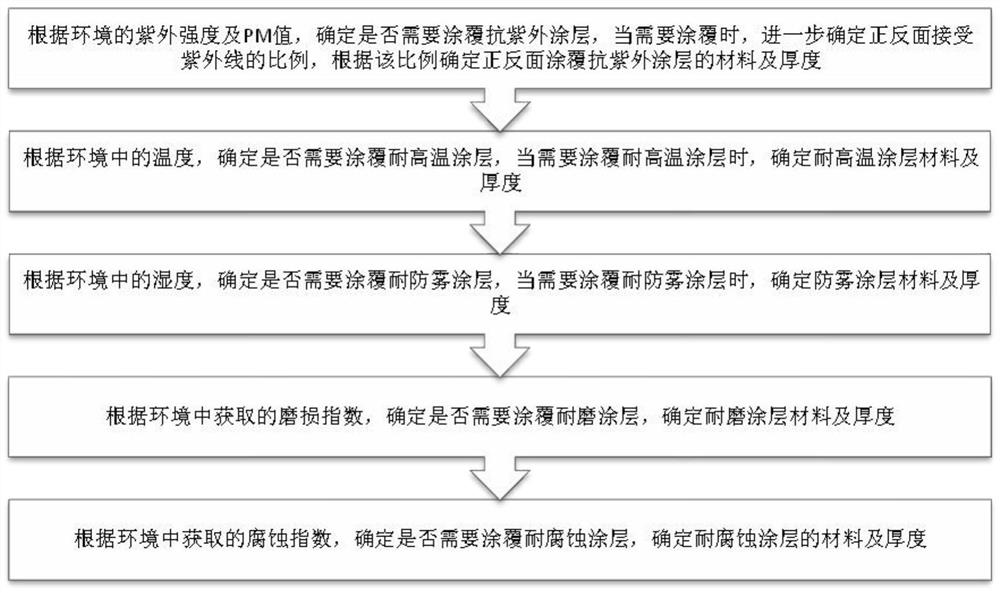

[0061] Determine the process parameters of the target PC solid sheet according to the corresponding environmental parameters; the process parameters include: anti-ultraviolet coating material and thickness, heat-resistan...

Embodiment 2

[0086] The definite process parameter in embodiment 1 is selected as:

[0087] a. According to the ultraviolet intensity and PM value of the environment, determine whether it is necessary to apply an anti-ultraviolet coating, further determine the proportion of the front and back receiving ultraviolet rays, and determine the anti-ultraviolet coating material and its content on the front and back according to this ratio;

[0088] b. According to the temperature in the environment, determine whether it is necessary to apply a high-temperature resistant coating, and when it is necessary to apply a high-temperature resistant coating, determine the high-temperature resistant coating material and its content;

[0089] c. According to the humidity in the environment, determine whether it is necessary to apply anti-fog coating, and when it is necessary to apply anti-fog coating, determine the anti-fog coating material and its content;

[0090] d. According to the wear index obtained i...

Embodiment 3

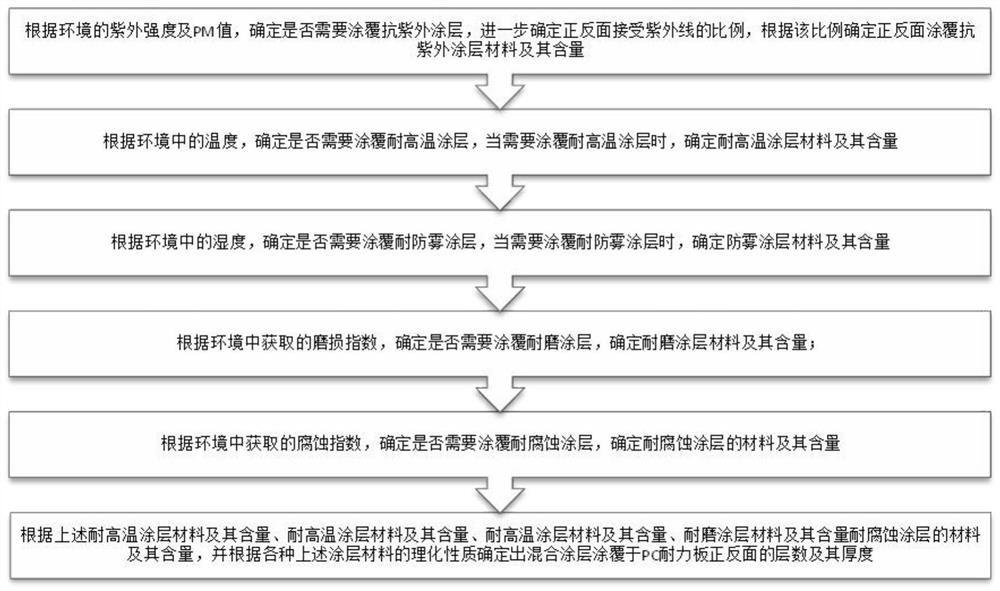

[0094] The determination process parameters in Example 1 are selected as: a, according to the ultraviolet intensity and PM value of the environment, determine whether it is necessary to coat an anti-ultraviolet coating, further determine the ratio of front and back sides receiving ultraviolet rays, and determine the front and back side coating according to this ratio Anti-ultraviolet coating material and its content;

[0095] b. According to the temperature in the environment, determine whether it is necessary to apply a high-temperature resistant coating, and when it is necessary to apply a high-temperature resistant coating, determine the high-temperature resistant coating material and its content;

[0096] c. According to the humidity in the environment, determine whether it is necessary to apply anti-fog coating, and when it is necessary to apply anti-fog coating, determine the anti-fog coating material and its content;

[0097] d. According to the wear index obtained in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com